Disordered Metals: Materials with Unique Properties

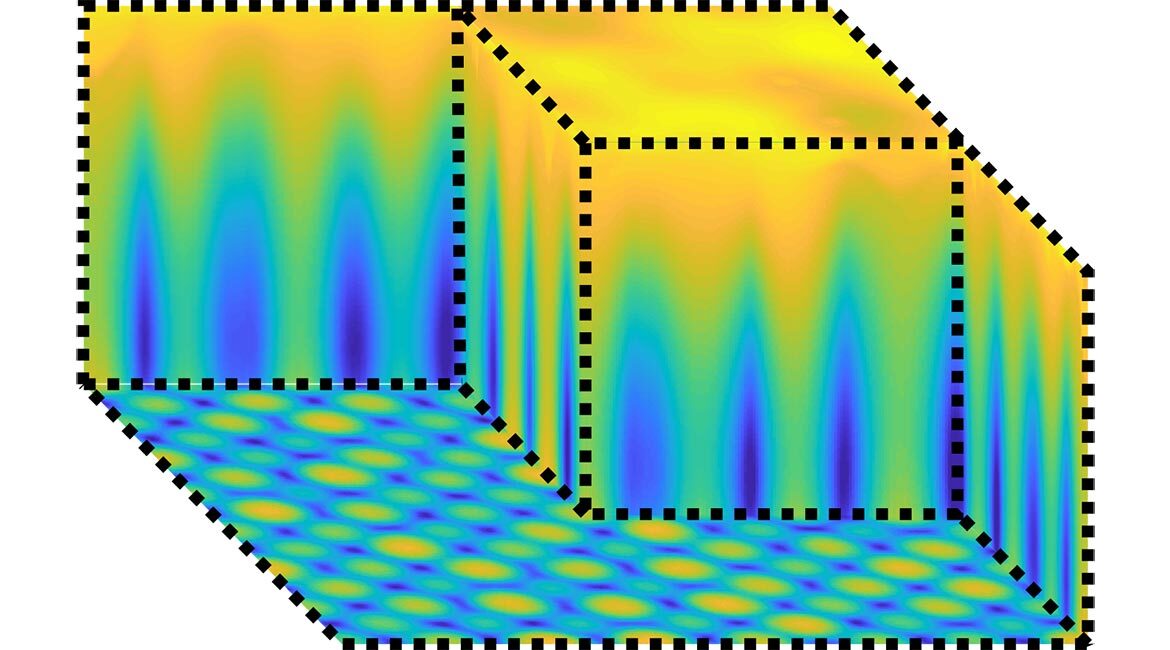

Property characterization of a material. @Omur Dadgeviren.

The atoms of the various metals and alloys that surround us are usually positioned at the lowest possible level of energy within a crystalline structure. This crystalline structure, although very stable, limits the mechanical properties that can be achieved, such as ductility, strength, and Young’s modulus, hence the interest in dismantling it and adjusting the materials to new application requirements.

Since the 1960s, researchers have been able to form amorphous alloys, i.e., alloys with a non-crystalline structure. One method used to achieve this is to cool very quickly the mixture of metals that will form the alloy, not giving the atoms time to reorganize. This rapid drop in temperature forces the atoms to stay put producing a bulk metallic glass.

Customized Properties

Disordered metal alloy compounds such as bulk metallic glasses, i.e., amorphous metals with no periodic crystal structure, are truly out-of-the-box materials because they combine properties in an unusual way. For example, they can be easily formed by molding, like plastics, but their strength is greater than iron. Strength, flexibility, and ductility can be increased at the same time. This combination of properties leads to many potential applications, in both the research and manufacturing fields. Characterization of these new materials becomes crucial in defining the optimal proportion of each component for the desired use.

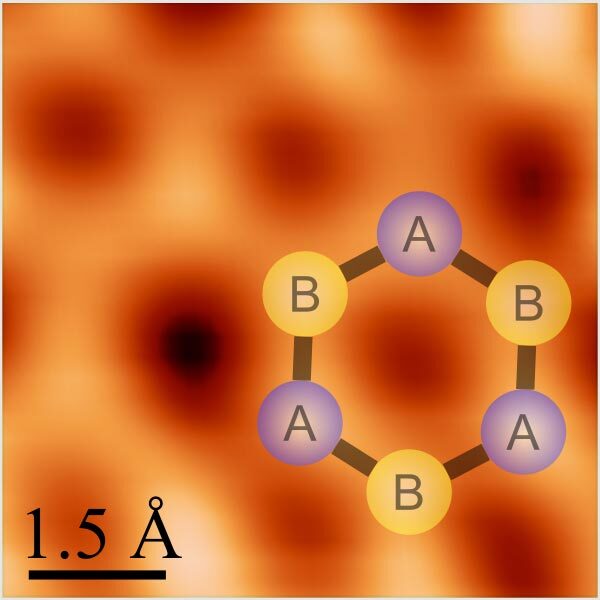

High resolution image of a material

Scanning Probe Microscope: An Investment of More than $1 Million

Thanks to a major investment by Canada Economic Development, ÉTS will acquire a state-of-the-art scanning probe microscope, specifically an atomic force microscope, and the first device of its kind in Canada. There are very few examples of this equipment in the world, given its high cost and the fact that it requires a specialist to operate.

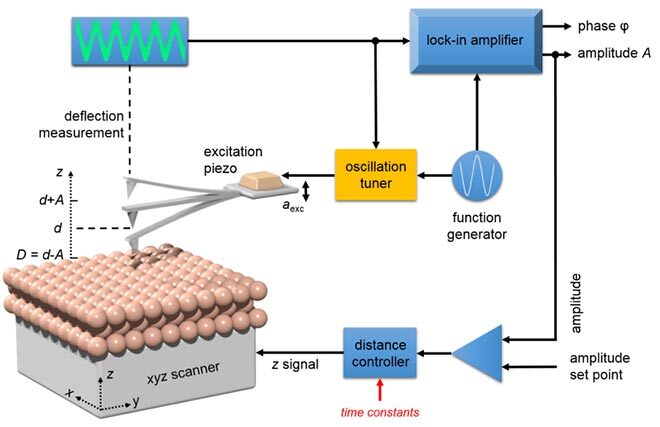

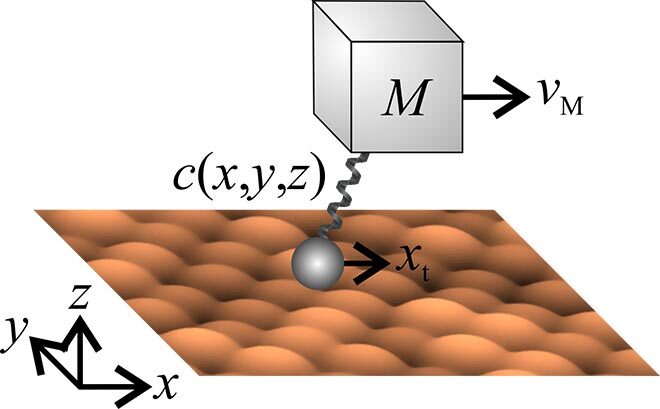

The device measures chemical, mechanical, and electrical properties at the same time using a small probe that oscillates very slightly, in the angstrom range (10-10 m). As the probe approaches the material to be characterized, it interacts with its surface, which can influence the resonance frequency, as well as the amplitude and phase of the oscillation. The material properties are obtained by correlating this information. The selected device is equipped with a closed refrigerant recirculation system to allow it to reach its operating temperature of 9 K, without having to use liquid helium. Another feature is that it operates very close to the absolute vacuum.

Scanning Probe Microscope operation

Scanning of the material surface.

This scanning probe microscope can analyze samples with up to four metals and will help industries create new materials, as well as meet more basic research needs. It will provide a unique competitive advantage to Canadian companies.

The Advanced Materials Characterization Laboratory is actively seeking Ph.D. students:

Characterization of Materials for Renewable Energy Applications

Nanoscale Characterization and Aim-Specific Design of Amorphous Materials

Interested parties may see the details of current projects and write to the author.