We use 74% more resources than the planet’s ecosystems can generate, or 1.7 times the resources produced by the Earth. And the total amount of solid waste we generate is only increasing. From 2012 to 2018, this waste increased by 16%, the equivalent of 35.6 million tonnes. In 2018, only 28% of the material generated was diverted from our landfills.

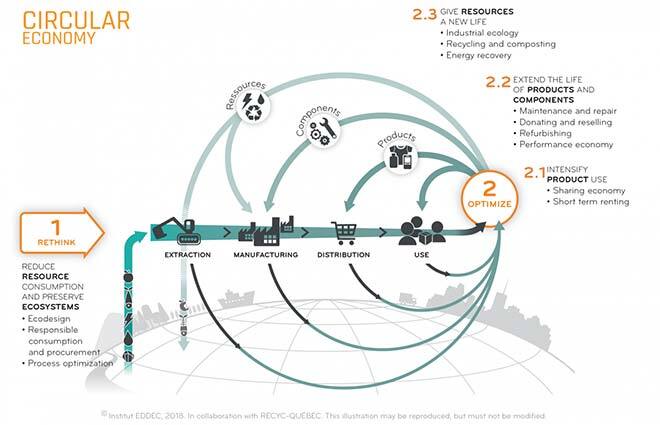

We need to rethink the economy and optimize flows in a circular way. In other words, we need to harness waste materials and reintegrate them into the production chain.

However, waste management presents a number of challenges. First, waste is made up of many different materials, each requiring a different packaging and recycling method. Second, demand is different for each of these materials. What’s more, the cost of virgin material is sometimes lower than that of recycled material. Even worse, we are woefully short of data on the volumes involved.

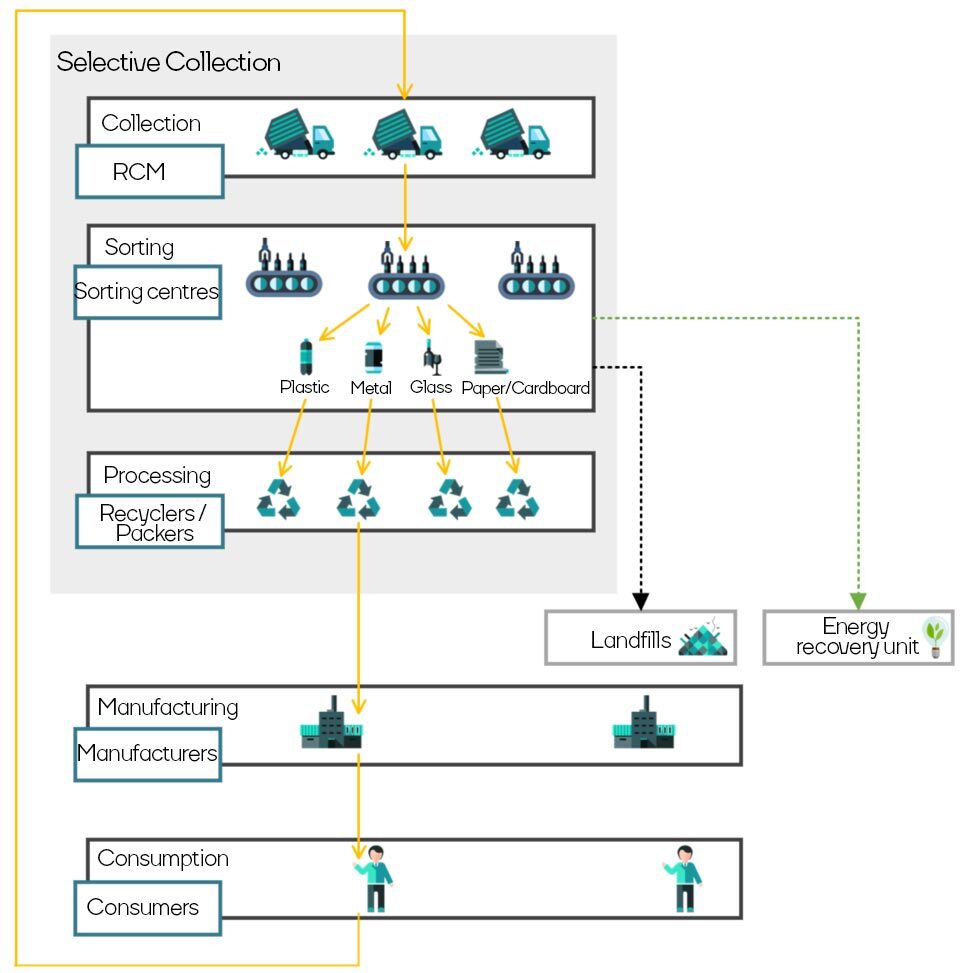

Waste Supply Chain

The chain begins with selective collection, where the contents of our blue bins are collected and taken to sorting centres. At these facilities, the materials are separated according to their type—plastic, metal, glass, cardboard. Some materials, like plastic, must undergo additional sorting according to resin and color, for example. Following these operations, part of the waste is sent to recyclers/packers, who process some materials so that they can be returned to the production system. The remainder is destined to energy recovery or ends up in landfills.

Our research focuses on optimizing the supply chain to minimize its economic, social and environmental costs. To achieve this, we must take into account material flows, transportation, and location of the various processing technologies.

We are working on three main areas of research:

- Quantifying manageable waste

- Examining new Industry 4.0 technologies

- Optimizing waste supply chains

Unknown Quantities of Waste

At present, the data available to us is tainted with a great deal of uncertainty, since no single organization has an overview of all the data. The data is fragmented among the various stakeholders, making it difficult to reach decisions and adopt the best strategies.

A new program, the Extended Producer Responsibility (EPR) program, is likely to change all that in the next few years. Managed by Éco Entreprises Québec, this program will make each producer responsible for managing the waste generated by its products. All data on the flows between stakeholders will be in the hands of a single organization.

Although implementing integrated management facilitates data access and chain management, uncertainty surrounding the generated quantities and quality of waste remains problematic. To address this, we are developing predictive models to accurately quantify the volume of the different materials to be managed. These models rely heavily on artificial intelligence, and take into account factors such as population density, seasonality, etc. A good approximation of the volume of materials to be managed is essential to optimizing the supply chain.

Industry 4.0: A Wealth of Potential Information

New smart garbage bins equipped with Internet of Things (IoT) sensors are showing up, bringing a number of opportunities. The garbage bins can assess their fill and the percentage of each material they contain. This information paves the way for better characterization of waste quantity and content. What’s more, applications like on-demand collection could be developed, with trucks picking up only garbage bins that are 70% full or more, for example.

Optimized Logistics Chains

Based on the quantities generated as calculated above, the aim here is to optimize transport and determine the best possible locations for sorting centres and the technologies involved in recycling materials. The objective is to increase yield and efficiency while minimizing economic, environmental and social costs.

A More Circular Supply Chain

Reintegrating residual materials into our production chains is one solution that must be put forward to counter the climate crisis. While a product is being designed, we must think about its end-of-life, thereby facilitating recycling of its components.