The Digital Human and its Use in Workplace Design and Ergonomics

In an age when the digital modeling of complex systems continues to evolve, the ultra-complex machine that is the human body is also subject to the digitization of reality. Research areas and challenges are numerous when reproducing only a few aspects of the human sensory and motor functions with a virtual simulation tool:

- From the skeleton to the physical envelope;

- From the postural prediction to the dynamic prediction;

- From the user experience to the autonomy of the digital human in a given situation.

The digital mannequin, or avatar, are terms used when referring to the digitized human in many fields such as medicine, industry, ergonomics, arts, and video games. This article will be dealing with the field of virtual ergonomics and DHM (Digital Human Modeling), with the Smart Posture Engine project. This project was initiated by Professor Rachid Aissaoui’s team, from the laboratory LIO (Laboratoire de recherche en imagerie et orthopédie), and in collaboration with the 3DS company (Dassault Systems).

Figure 1 Sia and Teo are the new DELMIA V6 mannequins for virtual 3D ergonomic analysis

3DS has specialized for the past 20 years in computer-aided design software (CAD) and Product Lifecycle Management solutions (PLM). One of their products, DELMIA, is a series of digital solutions created to simulate the environment of a factory and virtually define, plan, design, monitor, and control all production processes. Essentially, DELMIA can assist in creating a 3D model of the complex processes in manufacturing facilities such as those of Bombardier, Boeing, Airbus, Honda, Toyota, etc.

Virtual Ergonomics in Aviation

Virtual Ergonomics in Construction

The goal of the Smart Posture Engine project is to improve the positioning of the DELMIA’s mannequins by integrating physiological behaviors based on the latest developments in biomechanics. A multidisciplinary team is involved in the project: students and researchers from the École de technologie supérieure (ÉTS), in Montréal, the École Polytechnique de Montréal, and the 3DS virtual ergonomics team.

The main phases of the project are:

- Thorough analysis of the current DELMIA positioning engine to pinpoint the limitations and make improvements.

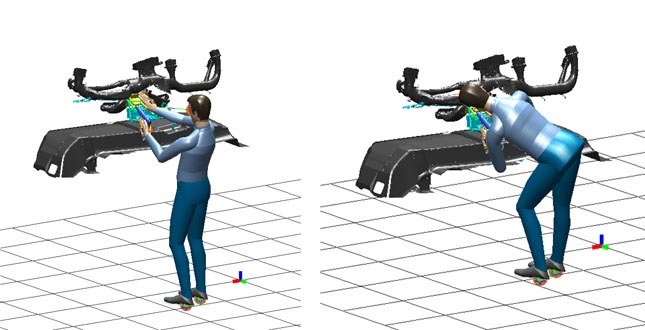

- Designing, with Matlab software (Mathworks, USA), a testing environment replicating DELMIA’s mannequin to program and test the various features of the positioning engine.

Figure 2 DELMIA V5 Mannequin using the Matlab environment for development and testing

- Thorough study of the body joints, adding constraints on multi-joint coordination (e.g. shoulder motion dynamics, vertebral coupling) for more realistic postures which will help solve several problems identified by the 3DS team.

(Left) current V5 DELMIA clavicula bone, characterized by exaggerated mobility, and lack of coordination between clavicula bone and upper arm bone. (Right) Clavicula bone with clavicula and upper arm bone coordination, and a more realistic mobility, reducing redundancy in the kinematic chain and the clavicula bone oscillation

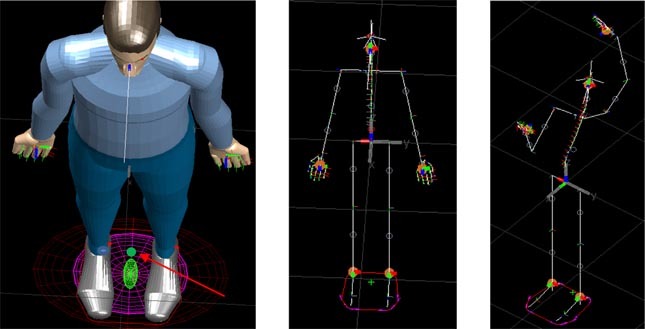

- Creating a balance index of the mannequin to quantify the stability of the predicted posture.

Figure 3 DELMIA Mannequin using Matlab with balance index (green dot) and support polygon (magenta area)

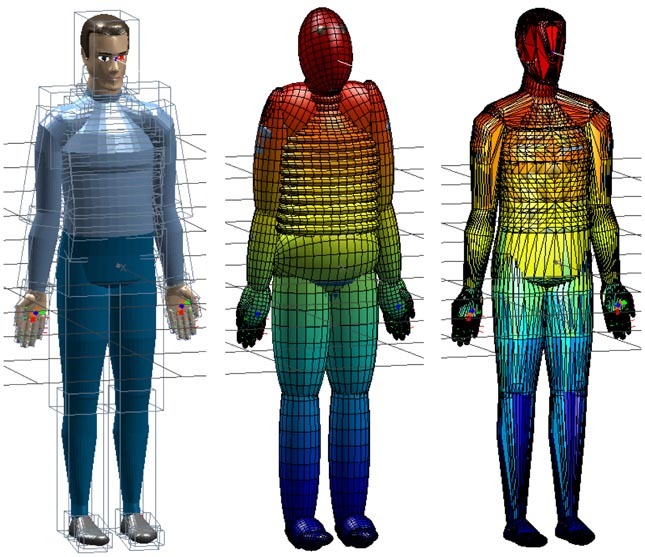

- Developing a method to avoid collisions with the mannequin itself and with its environment.

Figure 4 DELMIA Mannequin using Matlab with volumes for collision testing: OBB (left), ellipsoids (center), and convex hull (right).

- Creating a vision index of the virtual mannequin based on the visual acuity established in the field of optometry.

Figure 5 DELMIA Mannequin using Matlab. Left, line of sight (in cyan), near vision volume (in magenta) where the mannequin can be positioned to see the letter E (in black on the white square). Right, constraint in clear vision of a 9 mm object.

- Studying the link between the hand of the mannequin and the objects to grasp; define the types of grasps.

- Recognizing and characterizing the items to be grasped by the mannequin.

Two post-doctoral students of the LIO, Arnaud Barre and Pierre-Olivier Lemieux, are working together on the key components of the project. Five masters’ students in health technology (Benjamin Milluy, Matthew Cauffiez, Niels Eilstein, Quentin Bourret, and Yann Halgand) are conducting, or have already conducted, their 15-credit projects on the 3DS premises.

To learn more on the subject of Digital Human Modeling, please attend the DHM2016 conference, to be held on June 15, 16, and 17, 2016, at the ÉTS.

[accordion title=”Partners and stakeholders” close=”1″]

LIO (Imaging and Orthopaedics Research Laboratory)

LIO Team

Project manager: Rachid Aissaoui

Professor at the Automated Manufacturing Department-GPA ([email protected])

Co-researchers: Nicola Hagemeister et Jacques de Guise

Professors at the GPA department

Laetitia De Polo, project coordinator, École de Technologie Supérieure (ÉTS)

Arnaud Barré, post-doctoral researcher, GPA, École de Technologie Supérieure (ÉTS)

Pierre Olivier Lemieux, post-doctoral researcher, GPA, École de Technologie Supérieure (ÉTS)

Benjamin Milluy, masters’ student in engineering, health technology, École de Technologie Supérieure (ÉTS)

Niels Eilstein, masters’ student in engineering, health technology, École de Technologie Supérieure (ÉTS)

Matthieu Cauffiez,masters’ student in engineering, École de Technologie Supérieure (ÉTS)

Quentin Bourret, masters’ student, École de Technologie Supérieure (ÉTS)

ÉTS

Louis Rivest, Professor at the GPA Department

Yann Halgand, masters’ student, École de Technologie Supérieure (ÉTS)

Polytechnique Team

Daniel Imbeau, Professor

Sahar Arab, PhD student

3DS (Dassault Systèmes), DELMIA

3DS team

Julie Charland, Director, Virtual Ergonomics, 3DS

Jean-François Veaux-Logeat, R & D Director of Ergonomics Applications, 3DS

Hugues Carron

David Brouillette

[/accordion]