Building Trust in Wind Turbines with AI-Based Condition Monitoring

Purchased from Gettyimages. Copyright.

This article introduces an innovative condition-monitoring approach for wind turbines. It includes early detection and diagnosis of abnormal conditions. The approach applies an artificial intelligence model called Variational Autoencoder embedded with a classifier. It translates complex operational data into interpretable health indexes and actionable information. The proposed model includes a built-in visualization tool that enhances trust in the outcomes and facilitates clearer communication among analysts, operators, and technicians. The proposed approach was validated with real-world case studies and was shown to outperform competing approaches in the detection and diagnosis of critical conditions. Key Words: wind turbine; data-based condition monitoring; interpretable AI; visualization tool.

Building and Maintaining Trust in Wind Turbines Are Key!

In the fight against climate change, wind turbines stand out as a major technological solution. The wind energy sector is forecasted to generate over 35% of global power needs by 2050 [2]. Nevertheless, the path to scaling up wind turbine infrastructure worldwide hinges on public acceptance, competitive costs, financial drive, and stimulative government policies. All these requirements are strongly related to the trust of stakeholders in wind turbines as reliable and profitable assets. In this context, condition monitoring of wind turbines is paramount. Detecting and diagnosing abnormal conditions as soon as possible allows for the planning and effective implementation of interventions such as emergency shutdowns, inspections, and repairs. By resolving degradations before they become severe failures, operators ensure safety, reliability, and cost effectiveness throughout the wind turbine’s lifetime. Thus, condition monitoring models are key leverages to build trust in wind energy as a solution for a sustainable future [3].

Data-Driven Condition Monitoring of Wind Turbines: From Data to Actionable Insights

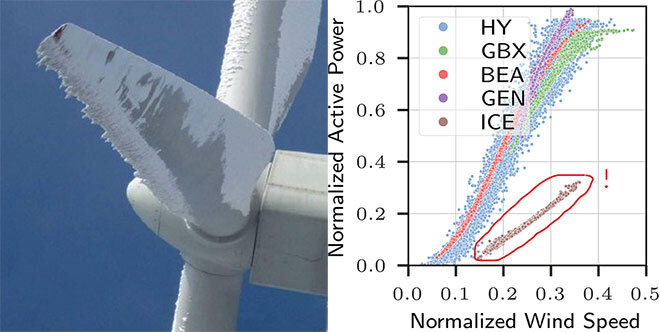

Modern wind turbines are equipped with a large number of sensors—typically, a large 5 MW unit includes over a hundred measurement channels [4]. Measures from these sensors give a detailed description of the wind turbines’ physical state. Operators currently leverage this data to analyze the health condition of wind turbines. Figure 1 shows two examples of critical abnormal conditions and the respective signatures in physical space measures.

Figure 1 Critical abnormal conditions in wind turbines. (a) Ice accretion on blades [5]. (b) ICE condition signature in wind speed versus active power plot.

(c) Main bearing with sheared-off and plastically deformed cage bars [6]. (d) BEA condition signature in rotor speed versus main bearing temperature plot.

Standard condition monitoring models focus on few measures, therefore missing out on much of the available data. Recent advances in computational power and artificial intelligence (AI) brought new possibilities in leveraging the ever-expanding wind turbine operational databases. Despite very promising results from AI models, their practical use is limited by concerns over interpretability and trust [7]. Our work [1] introduces a novel AI-based condition monitoring approach with a built-in visualization tool. Our aim is to convert raw data into interpretable and actionable insights for wind turbine operation.

A New AI-Based Condition Monitoring Approach for Wind Turbines

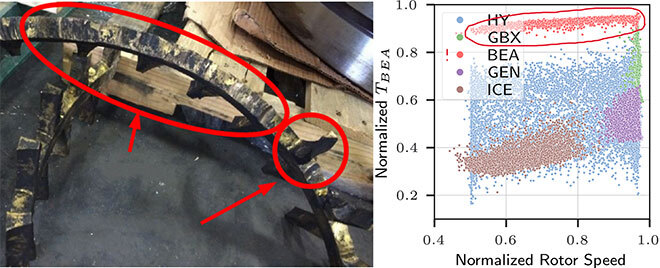

The realm of AI is diverse and rapidly progressing. Our work explored a specific AI model, the VAEC (Variational Autoencoder embedded with a classifier). This powerful model stands out in its ability to project a complex high-dimensional system into a low-dimensional representation space, typically a 2D space. This representation is called latent space and reveals the physical properties of the original physical space [8,9]. Operational data from a large wind farm allowed training of the VAEC model. Figure 2 depicts the corresponding latent space, where z1 and z2 are the latent variables. In this space, the HY cluster corresponds to a healthy operation. The other clusters are a projection of abnormal conditions such as BEA (main bearing overtemperature) and ICE (ice accretion on blades).

Figure 2 Diagram of the VAEC model. It includes the encoder, decoder, and classifier.

Once the VAEC is carefully trained and validated with a well-curated database of wind turbine operation, the projection of new data from a specific wind turbine gives information on its health state. We used the VAEC latent space to define a detection approach. Moreover, the model enabled the classification of the condition, hence the diagnosis. The proposed approach led to encouraging results, detecting wind turbine degradations earlier than competing approaches.

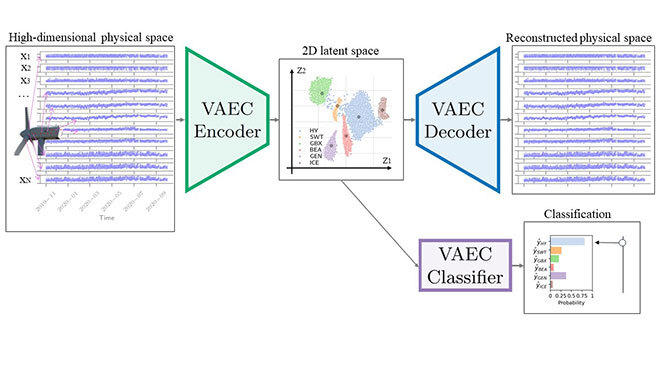

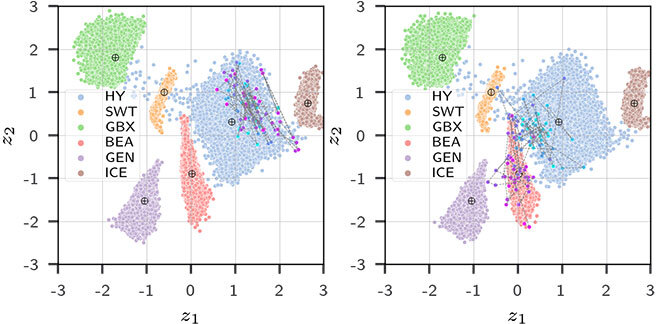

Another novelty in our proposition is using the latent space as a visualization tool. The 2D latent space makes complex data patterns understandable at a glance, enhancing the interpretability of the condition monitoring models. Figure 3 depicts the projection of two wind turbines within time.

Figure 3 Visualization tool projecting: (a) wind turbine in healthy condition; (b) wind turbine affected by the main bearing degradation.

Each projected point indicates the wind turbine condition on a given day, and the cyan-magenta colormap indicates the timeline progression. In Fig. 3 (a), the trajectory of the wind turbine remains in the HY cluster, suggesting this unit is in healthy condition during the period of interest. On the contrary, Fig. 3 (b) depicts a trajectory that starts—cyan points—at the HY cluster but later transitions toward the BEA cluster, indicating overheating of the main bearing. The authors believe this interpretable representation can enhance trust in AI model outcomes and facilitate communication between analysts, operators, and technicians. This visual representation can be a game changer in the condition monitoring of wind turbines.

Conclusion

The main contributions of our work are summarized below:

- The study presented a new approach for the early detection of abnormal conditions in wind turbines. The proposed approach applies the VAEC model to enhance interpretability and trust in the outcomes;

- A built-in visualization tool is part of the VAEC model. The representation space allows for clear and interpretable tracking of the wind turbine’s health condition over time. This enhanced interpretability eases communication and interactions between analysts, operators, and technicians;

- Real-world case studies demonstrated the effectiveness of the proposed approach in predicting and diagnosing abnormal turbine conditions earlier than competing methods;

- While the initial setup of this technology requires time and resources, once implemented, it offers a cost-effective solution for ongoing wind turbine monitoring.

For more details on the results presented in this short version, please refer to our paper [1]. Further investigation is ongoing and the results will be published soon. Stay tuned! Interested in research and coding for a sustainable energy sector? Our team is hiring! Feel free to contact us.