Special Optical Fibres and Doughnut-Shaped Beams—New Photonic Tools

Header image bought from Istock.com: copyright.

Single-mode optical fibres are currently used to carry data by light over thousands of kilometres. The rapid growth in data carried over the Internet in recent years is gradually bringing us closer to the physical limits of existing networks. Eventually, new specialty optical fibres will be needed to support higher data rates and avoid failures in the global telecommunication network. Specialty optical fibres are also increasingly being used in the design of all kinds of devices useful in many areas of industry and health technologies. Also, it is now possible to produce doughnut-shaped light beams, giving them outstanding properties and increasing opportunities for new light-matter interactions. On February 7, 2018, Professor Bora Ung of the École de technologie supérieure (ÉTS) in Montréal and ÉTS postdoctoral researcher Yann Facchinello will give a lecture on specialty fibres, doughnut beams and their applications in telecommunications, laser machining, sensors and health technologies at ÉTS in Montréal. This article is an overview of the different active research efforts and their areas of application in various fields.

Introduction—Conventional and Specialty Optical Fibres for Telecommunications

Optical fibres were developed in the 1970s by Corning. A very fine glass strand can guide light over very long distances and be used to transmit data [1]. However, these standard optical fibres, operating in single mode, will no longer be able to meet users’ ever-increasing needs. Several experts predict that the current telecommunication network will reach its data transmission limit in the next decade or so. To meet this challenge, special optical fibres that can carry more data than the conventional single-mode fibres are the object of several research and development studies in many countries. In Quebec, researchers from ÉTS and Université Laval are collaborating in this area of research.

This article presents different types of specialty optical fibres being investigated at ÉTS, namely multi-core, multi-mode, and fibres that can carry doughnut beams.

Although single-mode optical fibres do not belong to the special optical fibre category, we provide a short description below to highlight the differences between this type of conventional optical fibre and specialty optical fibres.

Single-Mode Optical Fibres (conventional)

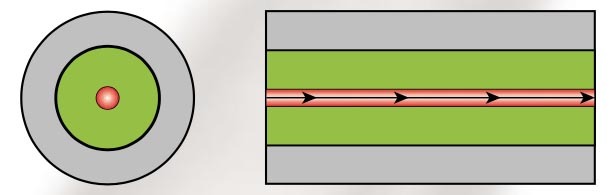

Single-mode optical fibres guide a light beam into the glass core (shown in red below) with a higher refractive index than the cladding (green), covered with a protective polymer coating (gray). The fibre’s core measures approximately 9 microns in diameter within a structure that in total measures less than 500 microns in diameter.

Figure 1: Single-mode optical fibre

The light beam guided in the fibre core has a Gaussian intensity profile that facilitates coupling of light emitted by laser sources.

Advantages and Disadvantages of Single-Mode Optical Fibres

Single-mode optical fibres can carry data over thousands of kilometres at the speed of light. Since only one light beam (i.e. one mode) is being guided, there is little chance of modal dispersion and crosstalk that would disrupt the signal during its propagation. Therefore signal transmissions in this type of fibre are relatively stable and the data rate is limited only by the physical capacity of the single-mode fibre.

Multicore Optical Fibres

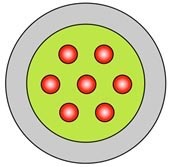

Figure 2: Multicore optical fibre

This type of fibre is made up of several cores—surrounded by cladding and a protective coating—that can carry one or more light beams.

Multicore optical fibres work on the same principle as a single-mode optical fibre. Over a dozen independent transmission channels can be integrated within adjacent cores. However, this type of fibre has a slightly larger diameter than conventional optical fibres. With its multi-core geometry, telecommunication links can be denser than with conventional single-mode fibres.

Multimode Optical Fibres

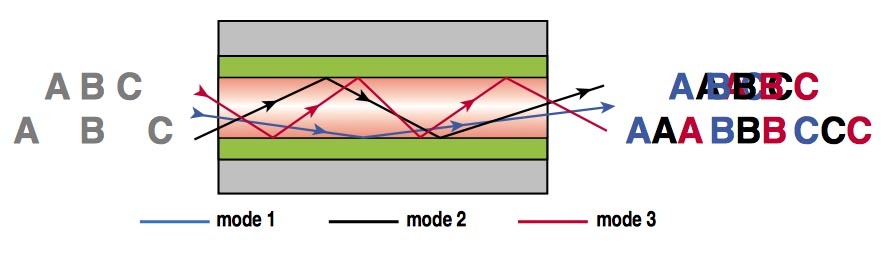

Since the advent of multimode optical fibres—in which each guided mode acts as an independent transmission channel—much higher spatial densification of communication links is now possible. In this type of fibre, several light beams (i.e. modes) run in parallel within the same core. In theory, the number of modes that can be injected into a multimode fibre is unlimited, which is very appealing. However, one major challenge in this geometry is the significant probability of interference between the copropagating modes, creating errors and signal losses, a phenomenon known as “crosstalk”. Another challenge comes from the slight differences in mode propagation speeds, known as “modal dispersion”.

These two factors currently limit the effective multimode transmission lengths with this new type of fibre. Researchers in this field are working hard on a global scale to solve these problems and to eventually develop practical and viable solutions that will have an impact on the fluidity of future telecommunication networks.

Figure 3: Multimode optical fibre

Doughnut Beam Multimode Fibres

The fibre laser market is closely linked with the progress of industrial laser systems.

Fibre laser technology has matured in recent years, providing cost-effective and reliable solutions integrating high-quality, high-power laser beams into a growing range of industrial and medical applications. Yet, transmitting doughnut beams in an optical fibre is not easy given the significant crosstalk within these fibres. Therefore, it is necessary to design multimode optical fibres specially adapted to doughnut-beam transmission. As part of ÉTS research activities, a new special fibre for doughnut beams has been developed and will soon be tested for applications in industrial lasers, multimode telecommunications and biomedical imaging [2].

In a Gaussian beam, maximum intensity is found in the centre, whereas in a doughnut beam, the maximum intensity is on its periphery, while its centre has practically no intensity (as shown in the above-mentioned video).

Doughnut Beam Multimode Fibres

The fibre laser market is closely linked with the progress of industrial laser systems.

Fibre laser technology has matured in recent years, providing cost-effective and reliable solutions integrating high-quality, high-power laser beams into a growing range of industrial and medical applications. Yet, transmitting doughnut beams in an optical fibre is not easy given the significant crosstalk within these fibres. Therefore, it is necessary to design multimode optical fibres specially adapted to doughnut-beam transmission. As part of ÉTS research activities, a new special fibre for doughnut beams has been developed and will soon be tested for applications in industrial lasers, multimode telecommunications and biomedical imaging [2].

Doughnut Beams in Super-Resolution Microscopy

In 2014, a Nobel Prize was awarded to E. Betzig, W.E. Moerner and S. Hell for their design of a super-resolution microscopy system called STED (STimulated Emission Depletion Microscopy) [3]. The key element of this innovation stems from the use of a doughnut beam. With the STED microscope, it is now possible to see biological structures measuring only a few nanometres, an accuracy greater than the diffraction limit of light, considered until recently as an inaccessible frontier.

Despite the undeniable power of STED microscopy, systems currently on the market are very costly, restricting this technology to specialized medical and pharmaceutical research institutes. Research is being done at ÉTS to democratize STED technology through the use of specialty optical fibres.

Optical Fibres as Sensors

Optical fibres can also be used as sensors in numerous manufacturing and biomedical areas: measuring temperature, humidity, mechanical stresses and biomedical parameters. Note that optical fibres have certain advantages over electronic sensors:

- No electromagnetic field emissions and impervious to them

- Thin and compact

- Low power requirements

- Large bandwidth

- Biocompatible and low cost

Distributed Sensors

A distributed sensor is an optical fibre that can measure physical disturbances along its entire length (from a few metres to several kilometres). With a few milliwatts of optical power injected into the core, the fibre can measure constraints applied to it as well as their specific location. A large number of electronic sensors would be needed to have the same effectiveness as a distributed fiber-optic sensor.

Research is underway at ÉTS to develop distributed fibre sensors that take advantage of the modal diversity in multimode fibres.

Biomedical Fibre Optic Sensors

A multidisciplinary team from ÉTS, bringing together professors Bora Ung (Electrical Engineering), Éric Wagnac (Mechanical Engineering), and postdoctoral researcher Yann Facchinello, in collaboration with hospital stakeholders such as Dr. Jean-Marc Mac-Thiong, orthopedic surgeon at the Sacré-Coeur Hospital in Montreal, are conducting research in the development of fibre-optic sensors and, more broadly, optoelectronic sensors, for biomedical applications.

Image 1: Optical fibers inserted into an artificial spinal cord

The team designed a deformation sensor made of a thin optical fibre implanted in an artificial spinal cord (image below) [4]. The goal of this research is a better understanding of the complex dynamical biomechanisms that occur in spinal fractures and their impact on the nervous system.