Simulating Strengthened Reinforced Concrete Beams

Provided by the authors. CC License.

Shear failure in reinforced concrete (RC) beams has always been a major concern for engineers, particularly in deep beams such as RC girders. Using externally bonded (EB) fibre-reinforced polymer (FRP) composites for shear strengthening of RC beams requires knowledge and experience, given the probable premature bond failure, the complex behaviour at the interface between FRP composites and concrete substrate, as well as the fracture mechanics of concrete that does not contain homogeneous materials. The aim of this research is to gain an in-depth insight into the maximum load transferred through interface layers and, consequently, the ultimate load carried by RC beams strengthened in shear with EB-FRP composites through analytical and finite element (FE) approaches.

The Finite Element Approach

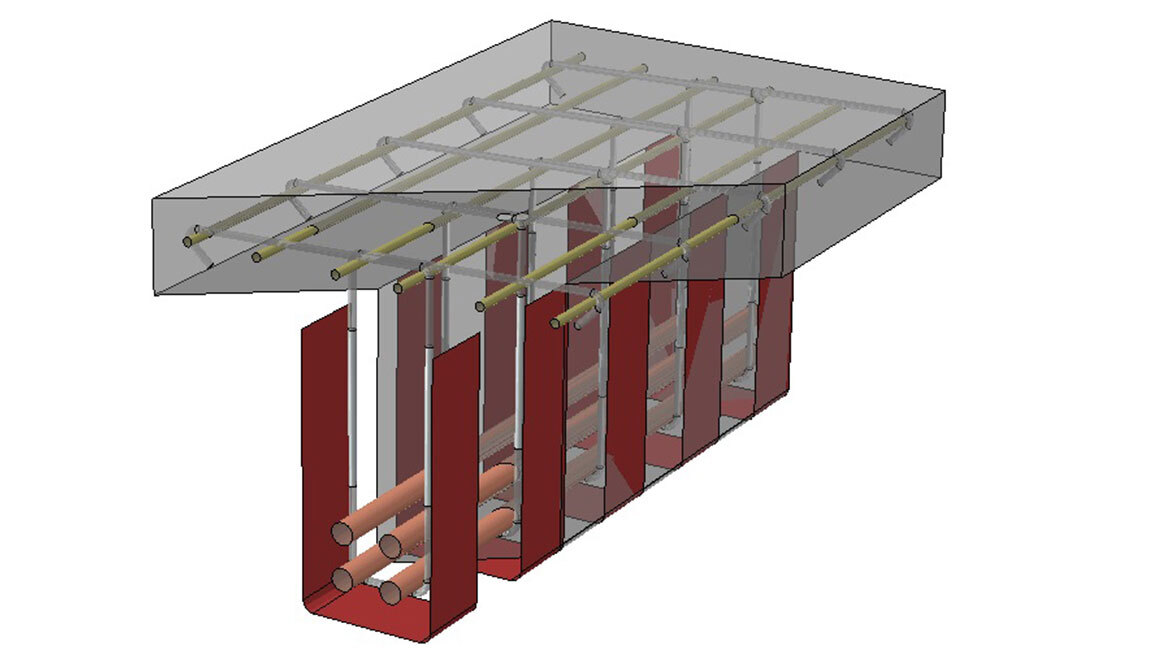

In the last two decades, very few FE studies have been dedicated to RC beams strengthened in shear with EB-FRP or any type of strengthening with composite materials [1] made of carbon fibre-reinforced polymer (CFRP) [2,3]. However, due to the lack of appropriate constitutive laws at the time, these early FE studies did not take into account the contact between concrete and FRP, nor did they replicate the interaction between concrete and steel reinforcement.

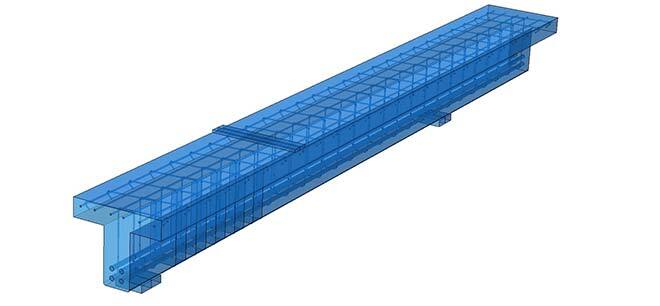

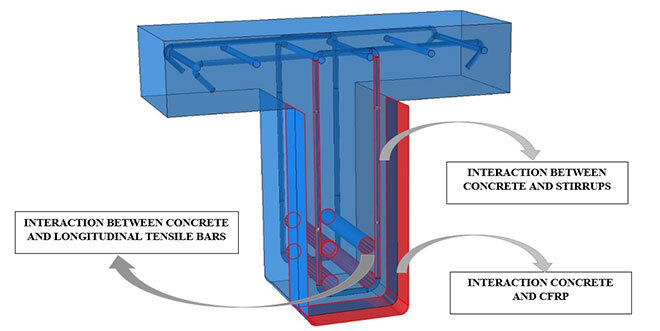

Figure 1. RC beam strengthened in shear with EB-CFRP simulated in ABAQUS and Interaction between main components

It has been established that when the beam size is increased, the shear strength decreases due to the so-called size effect [4,5,6]. Many parameters, such as the rigidity of FRP sheets [7], affect the size effect, either mitigating or amplifying it by controlling the width of the diagonal shear crack. Even though comprehensive studies have been carried out on the effect of size in RC beams, research studies related to the size effect on RC beams strengthened with EB-FRP are limited. FE analysis can be implemented instead of experimental testing to obtain an inside view of the shear-stress profile variation along the interface layer and the distribution of stress on the fibres during loading. The FE method is a cost-effective and precise tool for replacing experimental tests as long as the models are simulated based on reliable and logical assumptions and validated with experimental results.

Validation with Experimental Tests

Experimental Tests on Concrete Reinforced with Composite

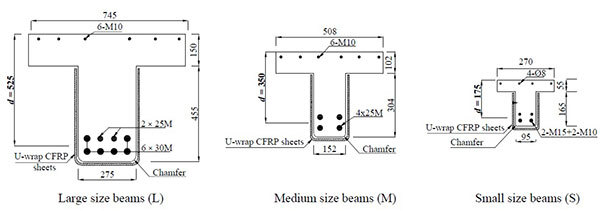

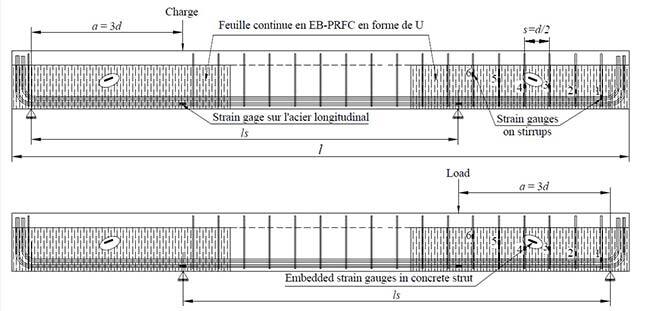

Nine RC T-beams without steel stirrups were selected from the experimental tests (control and strengthened) using EB-CFRP conducted by [7] to investigate the size effect by means of FE analysis (FEA). In addition, this study assessed the impact of increasing the rigidity of EB-CFRP on its contribution to the shear resistance of RC beams. Details of geometry, steel reinforcement position, and configuration of EB-CFRP are provided in Figure 2. The results are presented in terms of: (1) load-deflection responses; (2) strain profiles along the normalized diagonal shear cracks; (3) strain profiles along the fibre direction; and (4) variation of interfacial shear stress profiles along the cohesive layer.

(a)

(b)

Figure 2. Details of beams: (a) Cross-sections of geometrically similar T-beams (mm); (b) Typical elevation and internal instrumentation

Evaluation of Stirrup Interactions through Simulations

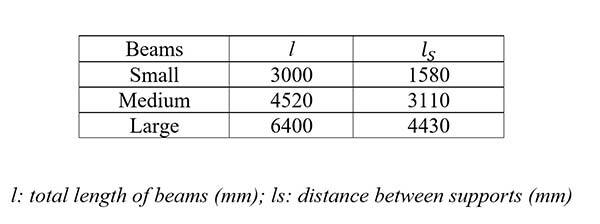

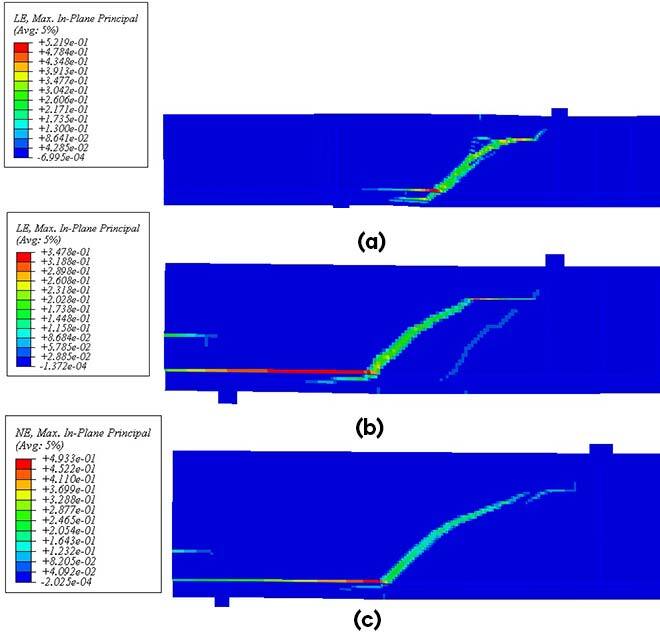

Since the aim of this research is to restrict shear cracks in concrete with the assistance of EB-FRP composites, the first issue would be to identify the beam region where shear cracks occur. By defining concrete damage plasticity in ABAQUS (FE software), the number and orientation of the cracks can be recognized. Therefore, by finding the crucial area in the RC beam where shear cracks occur, the design of CFRP composites would be optimized. Based on the maximum plastic strain in the plane of the concrete, ABAQUS identifies the stiffness degradation in the concrete and, thereby, helps to detect the plane and orientation of the cracks.

Figure 3. Propagation of flexural and shear cracks in RC beam with increasing load

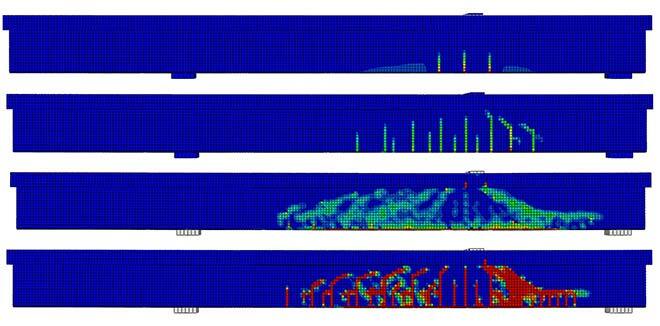

For the interaction between stirrups and concrete in this specimen, a cohesive layer was defined, after which the property of the CEB-FIP (design code for concrete structures) bond-slip model was assigned to this cohesive layer. The bond between longitudinal tensile bars and concrete was considered as perfect in order to exclusively evaluate the effect of stirrup interactions. For this comparison, only those stirrups located in the same area as CFRP strips will be evaluated (Figure 4).

Figure 4. (a) Distribution of Von Mises stresses on steel reinforcement; Position of CFRPs; and (b) Stirrups toward each other in the simulated specimen

Validation of the Model

As previously noted, the experimental tests conducted by [7] were used to validate the simulated model. The beams of one- and two-layer strengthening and the control beam had discretization elements in sizes of 5 mm, 10 mm, and 10 mm for small, medium, and large beams, respectively. Comparison of numerical and experimental results have yielded high agreement for all these sizes.

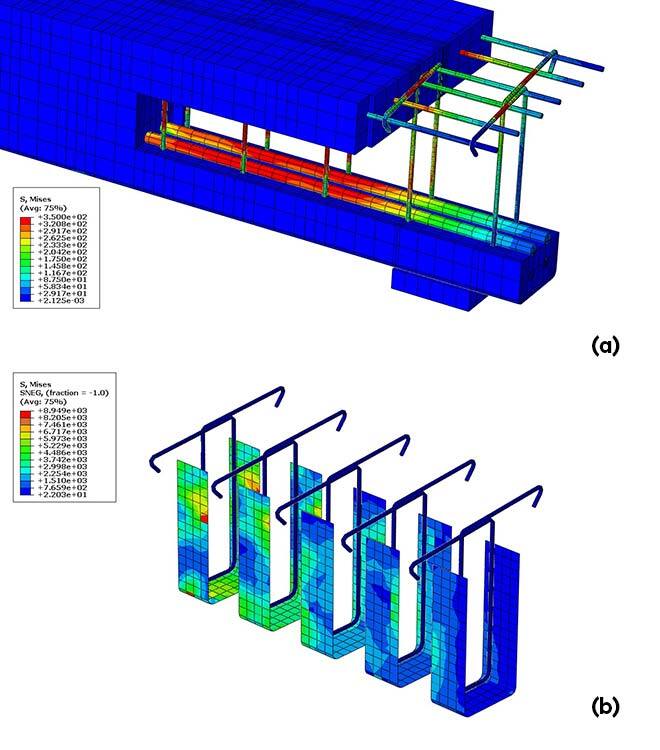

A single diagonal shear crack appeared as a crack band at the centre of the web and spread toward the web soffit (support) and the flange (stress point of application) of the control beams during experimental tests on small, medium, and large beams. The largest crack angle, as depicted in Figure 5, was at the midpoint of the beams, and gradually decreased as the fracture moved toward the support and the load application zone. The crack patterns predicted by numerical analysis and the corresponding experimental results were in agreement (Figure 5 a–c).

Figure 5. Crack pattern obtained from FEA and experimental testing for control beams at ultimate states: (a) S.0L.Con; (b) M.0L.Con; and (c) L.0L.Con

Conclusions

With an emphasis on the size effect on shear resistance of RC beams shear-strengthened with EB-CFRP, this research study has reported on advanced FE modelling of RC beams strengthened in shear with EB-FRP fabrics. The FEA results and the experimental results were in agreement. Nine RC-T beams were simulated in ABAQUS, including three control beams and six strengthened beams in shear with EB-FRP. If the assumptions are correctly defined, the numerical results from the FE model that were related to the shear crack pattern show that the suggested FEA is capable of accurately capturing the reaction of RC-T beams strengthened with EB-FRP.

Additional Information

For more information on this research, please read the following articles: Abbasi, A., Benzeguir, Z. E. A., Chaallal, O., & El-Saikaly, G. (2022). FE modelling and simulation of the size effect of RC T-beams strengthened in shear with externally bonded FRP fabrics. Journal of Composites Science, 6(4), 116.