Self-Healing Concrete Using Superabsorbent Polymer

Provided by the authors. CC License

Concrete is so sensitive to tensile stress that cracking is common in reinforced concrete structures, such as buildings and bridges. Cracking in concrete affects the performance and durability of structures. Repairing cracked concrete is costly and remains inefficient in many cases. To ensure good performance, initial cracks should be controlled and, if possible, repaired at their earliest stage. This research studies smart concrete, using a superabsorbent polymer (SAP) to seal and heal cracks autogenously. An extensive experimental program including pull-out tests on different concrete mixes was carried out to study the healing of concrete at rebar-concrete interfaces. Results show the promise of significant strength recovery using SAP to partially seal and heal cracks. Keywords: cracked concrete; self-healing; superabsorbent polymer; crack-sealing

Intelligent Concrete

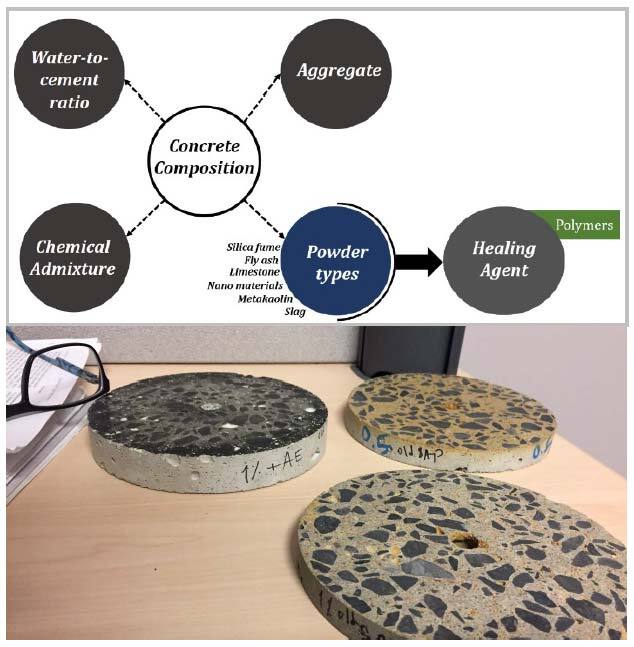

A reinforced concrete (RC) structure can be exposed to different loading conditions and exposures during its life cycle, causing varying levels of internal damage (Mousavi et al., 2019b). If these initial cracks are not controlled, the performance and security of concrete structures can be compromised, while repairing such cracks is generally inefficient or too costly. Concrete cracking significantly affects the mechanical characteristics of RC members, especially reinforcing bar-concrete bond behaviour and strength (Mousavi et al., 2020a). Hence, researchers have been working on a new generation of concrete mixture, known as “smart concrete”, to detect any internal damage intelligently, and then control the existing condition to impede the unexpected failure. This intelligent concrete mixture gradually controls damage as cracks emerge. Concrete composition plays a major role in this new generation of concrete (Mousavi et al., 2017; Mousavi et al., 2016) and can also be used to control internal damage by the appropriate use of healing agents within the mixture. The concrete composition is defined by four important parameters including admixtures, aggregate, water-to-cementitious material ratio, and powder (Figure 1). Changing each of these factors in both areas of quality and quantity can significantly affect the mechanical characteristics (Sfikas and Trezos, 2013).

Figure 1: Concrete composition as a key parameter in a self-healing method

Autogenous Self-Healing of Concrete

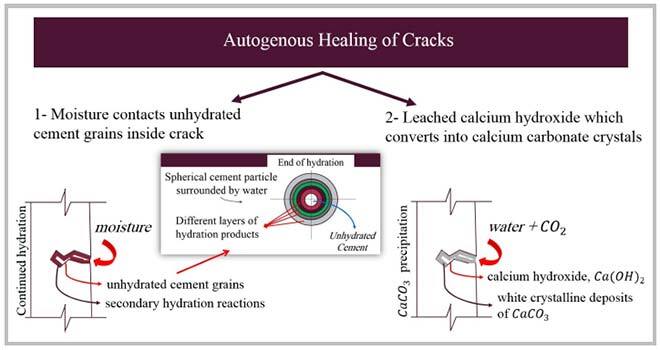

Combining cement and water produces an efficient binder of the aggregate in concrete; this is called the “hydration process” and the cement particles are called “hydrated particles”. However, some unhydrated particles always remain in the mixture, due to a lack of accessibility of water content. These particles can be useful to heal and seal potential cracks. The procedure of using these particles for healing cracks is called the “self-healing” or “autogenous healing” method. This ability is a promising solution to alleviate internal damage. The self-healing method can be mainly attributed to two mechanisms (Figure 2) including (1) hydration of unhydrated cement particles, and (2) dissolution and subsequent carbonation of Ca(OH)2. However, regarding crack width there is a serious limitation as to the efficiency of autogenous healing of concrete with no healing agents within the mixture (Mousavi et al., 2019a). As water is always needed for autogenous healing to occur, different types of water supply like superabsorbent polymers (SAP) have been used to accelerate the healing process.

Figure 2: Self-healing process in cracked concrete

Superabsorbent Polymer

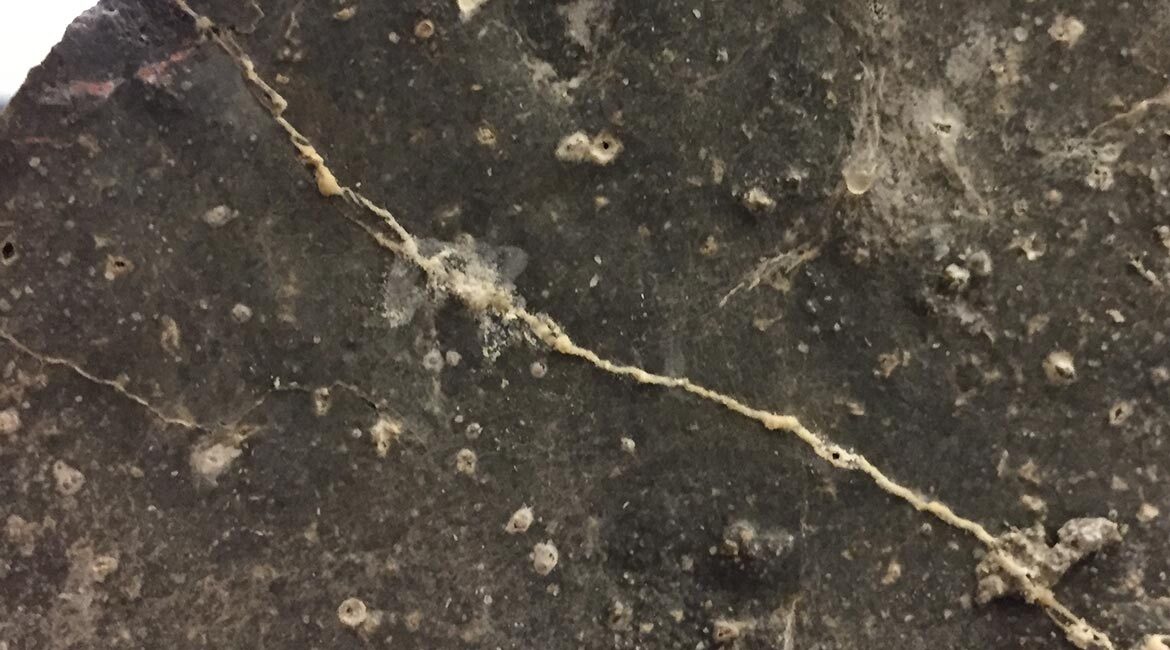

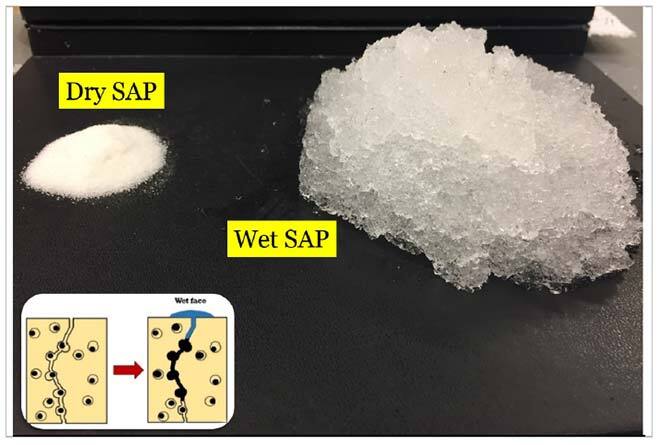

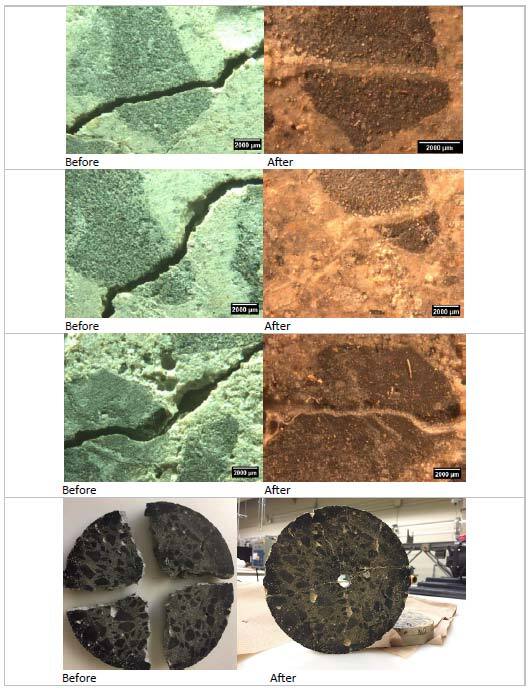

Hydrogels, or superabsorbent polymers (SAPs), have the ability to absorb a significant amount of water from the surrounding environment and to retain water within their structure without dissolving (Figure 3) (Mousavi et al., 2020b). SAP particles gradually release the absorbed water, reactivating the hydration process through the mixture, in other words, hydrating the unhydrated binder (cement) particles. SAP particles promote self-healing by providing water to crack formations, which results in a visual crack closure and gains in mechanical properties. As shown in Figure 4, primary results of the present research confirm that SAP-containing concrete has a high potential to seal crack width. However, different healing periods were considered for the specimens, shown in Figure 4.

Figure 3: Swollen SAP particles (with a diameter of 0.5 mm) after water absorption (the same weight is used for both dry and swollen SAP, 5 gr)

Figure 4: Healed specimens before and after healing periods

Research Parts

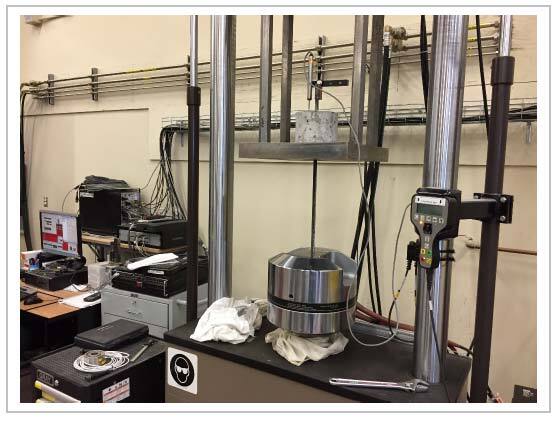

Crack sealing means closing the width of the initial crack to impede penetration of chloride ions and other corrosive agents. However, crack healing is the process of strength recovery after the initial damage. To measure strength recovery (regaining strength), reinforcing bar-concrete interface bond behaviour was considered in the present research through pull-out testing (Figure 5).

Figure 5: Pull-out test set-up

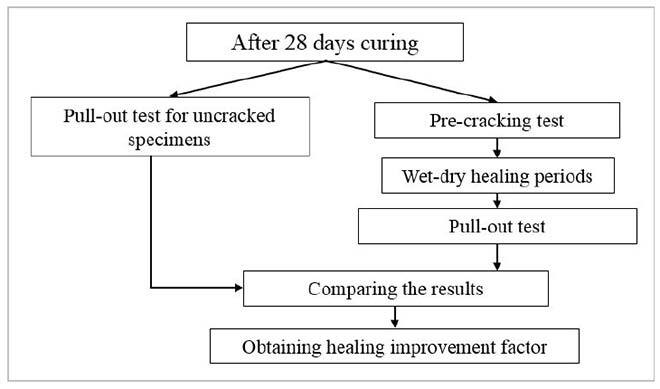

Reinforcing bar-concrete bond strength and behaviour play a major role in the structural performance of RC buildings and bridges (Guizani et al., 2017). In order to simulate internal damage, a pre-cracking process was considered in the experimental plan, followed by healing periods to seal and heal the cracks. Then, a comparison study was conducted between intact concrete, cracked, and healed specimens. Different concrete mixtures and SAP ratios were tested in the present research. A simplified experimental plan of the present research is shown in Figure 6. Similar to crack sealing (Figure 4), promising results were obtained for crack healing after healing periods. This research aims to identify a novel self-healing solution, more adapted to reinforced concrete, for self-repair infrastructure.

Figure 6: Simplified experimental plan of the present research

Additional Information

Summary of our results can be found in these recently published papers:

Mousavi, S., Ouellet-Plamondon, C., and Guizani, L. (2019a). Effect of superabsorbent polymer on mitigating damages at steel bar-concrete interface. In “CSCE Annual Conference”, Laval (Greater Montreal).

Mousavi, S. S., Guizani, L., and Ouellet-Plamondon, C. M. (2019b). On bond-slip response and development length of steel bars in pre-cracked concrete. Construction and Building Materials 199, 560-573.

Mousavi, S. S., Ouellet-Plamondon, C. M., Guizani, L., Bhojaraju, C., and Brial, V. (2020b). On mitigating rebar–concrete interface damages due to the pre-cracking phenomena using superabsorbent polymers. Construction and Building Materials 253, 119181.

Partnership

The authors would like to thank SNF CANADA and BASF for providing the superabsorbent polymers used in the current study.