Abstract: This article describes research on the configuration of a reverse logistics network. Reverse logistics refers, among other things, to recycling materials at the end of product lifecycle [1]. Given the importance of environmental issues, improving material recycling opportunities has become crucial to sustaining the planet’s resources for future generations. The Quebec construction sector consumes a lot of materials of all kinds, including an impressive quantity of wood [2]. However, at the end of building lifecycles, most of this wood is disposed of in landfills, although it is an easily recyclable material. The objective of our research is to propose a way to optimize lumber recycling in Quebec.

Research Problem

Today, the major role of recycling in preserving the environment is well established. However, although this finding is obvious in theory, its implementation can prove more complex. One of the main reasons for this is the great uncertainty in recycling activities: how much material will be recovered? What will the quality of these materials be and what will they be used for? Therefore, choosing a logistic network configuration to optimize recycling operations, in particular for wood, is a highly complex, yet critical, strategic issue. Right now in Quebec, disposing of wood in landfills is financially more profitable than the recycling option. Part of the problem is that the reverse logistics network in the construction sector is inadequate, and the excessive cost of recycling materials encourage their disposal.

Methodology: Developing a Decision-Making Tool

In our work, a mathematical model was developed to optimize timber revaluation processes. The proposed optimization model makes it possible to consider multiple scenarios for the coming years and take into account a large number of possibilities, which will help make the best decision by knowing all the risks [3]. We considered three types of uncertainties recurrent in the Quebec construction sector:

- quantity of collected wood,

- wood quality,

- location of collection sites.

This led to the development of different scenarios, and the model can identify recycling centres to relocate, considering adjustments of capacities allocated to each centre. It also determines whether an existing recycling centre needs to be closed, and optimizes all recycled wood transport flows to minimize recycling costs and makes this option more attractive than disposal, which remains financially profitable for the time being when compared to recycling.

Results of the Experiments

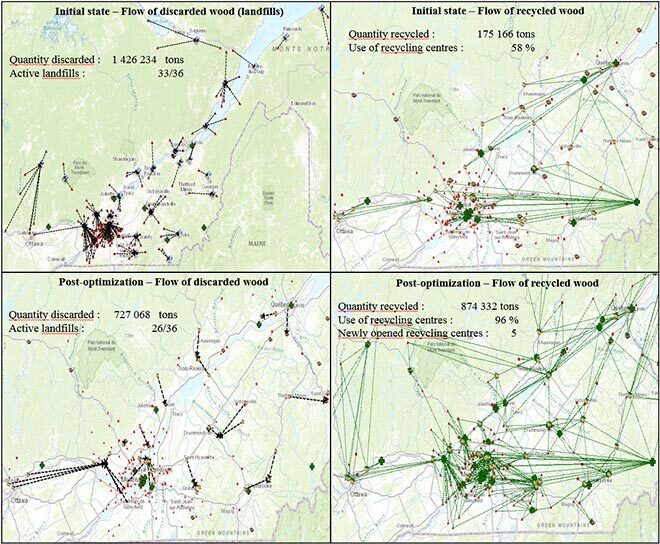

The optimization model developed in this article has been applied to a case study in the province of Quebec. The data include information on actual locations of the infrastructure as well as quantities of wood recovered at local construction, renovation and demolition sites. In Figure 3 below, the upper portion representing the base scenario (average quality and volume of wood collected) shows the drastic improvement brought about by the mathematical model’s suggested adjustments (lower portion).

In total, 26 recycling centres see an adjustment of their capacity or are relocated and 5 new centres opened to accommodate additional wood volumes. With the logistics network optimization, 874,332 tons of wood can be recycled compared to only 175,166 tons initially, while the quantity going to landfills can be cut in half. This is partly due to the optimization of transport flow in the network. In fact, in the optimized scenario, the average distance travelled to recycle a ton of wood is 75.4 km vs 116 km in the initial scenario. Also, the capacity adjustments lead to a recycling centre utilization rate of 96% vs 58% previously, as well as the closure of 7 out of the 33 landfills used initially. In scenarios where collection site locations, wood quality and collected volume vary, the model suggests the best adjustments to the reverse logistics network in order to recycle as much wood as possible.

Conclusion

This research involved the development of an innovative decision-making tool to optimize the reverse logistics network in revaluing materials at their end of the lifecycle. We applied this optimization model to the Quebec construction sector to optimize the wood recycling process and make it more attractive than landfill disposal. This research considers several limitations of current decision-making tools, including:

- dynamic supply sources in developing the reverse logistics network;

- specificities as opposed to generalities of the wood recycling sector [4].

- discussions on a reverse logistics network configuration, a rare approach in the construction sector and non-existent for recycled wood.

Additional Information

For more information on this research, please refer to the following paper:

Trochu, J., Chaabane, A., & Ouhimmou, M. (2018). Reverse logistics network redesign under uncertainty for wood waste in the CRD industry. Resources, Conservation and Recycling, 128, 32–47.