Heating a Greenhouse with Data Centre Waste Heat

Image purchased on Istock.com. Copyright.

Infrastructure expansion required for data management brings a steady increase in energy requirements for data centres. Data centre operation produces a significant amount of waste heat that could be recovered, for example, to heat Quebec greenhouses in winter. This study presents the energy consumption and greenhouse gas (GHG) emissions associated with heating a greenhouse with a heat recovery system from a data centre equipped with a heat pump. The heat pump is needed to raise the air temperature rejected by the data centre to an adequate level to heat a greenhouse (60° C). The energy and environmental performance of this innovative greenhouse is then compared to a conventional greenhouse equipped with a propane unit heater. The heat recovery system reduces energy consumption by 66% and, considering the low GHG emissions from electricity produced in Quebec, reduces GHG emissions associated with the greenhouse operation by 91%. Keywords: greenhouses, data centre, heat recovery, dynamic thermal simulation.

Energy Consumption Associated with Greenhouse Heating in Quebec

In Quebec, the production period for small-scale greenhouses is often limited to seven months (April to October) due to significant energy consumption caused by heating and artificial lighting in winter (MAPAQ, 2018). An IRDA report (2017) notes that a 1750 m2 greenhouse in St. Hyacinthe, Quebec, requires 730 kWh.m-2 annually in heating to maintain the indoor air temperature at 18 ℃.

In addition, systems providing heat to greenhouses are generally powered by fossil fuels, which significantly increases the ecological footprint of the Quebec greenhouse sector (MAPAQ, 2018). Also according to the IRDA report (2017), GHG emissions caused by heating a 1750 m2 St. Hyacinthe greenhouse at 18 ℃ with propane are about 200 kg CO2 eq.m-2. The availability of a clean electricity grid could be leveraged to reduce energy costs and the environmental impact of greenhouses in Quebec.

Waste Heat Produced by Data Centres

Equipment (servers) installed in data centres produce enough heat to require the use of dedicated cooling systems. In Canada, data centres consume about one percent of all the annual electricity consumed, 40% of which is used to cool the spaces (Natural Resources Canada, 2016). Servers can be cooled by air convection or water-cooled components (Oró, Allepuz, Martorell, & Salom, 2018; Oró, Taddeo, & Salom, 2019). In all cases, it is technically possible to recover the waste heat generated.

Using Data Centre Waste Heat for Greenhouses

In this case study, a dynamic thermal simulation model of a greenhouse’s energy performance was developed in TRNSYS to evaluate the potential of using waste heat from a data centre server room to heat a greenhouse. The data centre and greenhouse are located in Baie-Comeau, Quebec (49.2° N, 68.2° W). The greenhouse is a 153 m2 gothic-arched structure with a two-ply polyethylene film envelope. The maximum heating capacity of the greenhouse is estimated at 96 kW (Cousin & Lekounougou [2020]).

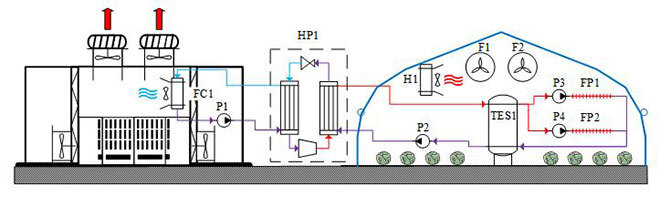

Cooling the servers in the data centre is done through cool air convection and hot air is evacuated through exhaust stacks. A server room produces 1 MW of waste heat (Cousin & Lekounougou, 2020). It is proposed to recover this waste heat with a recovery system as shown in Figure 1. The system consists of a hydronic fan coil unit (FC1) connected to the water-to-water heat pump evaporator (HP1). The heat pump raises the water temperature to 60 ℃ to heat the greenhouse air using the condenser water loop. The produced heat is stored in a hot water tank (TES1) located in the greenhouse. The stored hot water feeds two finned pipe networks (FP1, FP2) that provide heating to the greenhouse air when needed.

Figure 1: Proposed data centre heat recovery system

The impact of crops on the greenhouse energy balance is also considered since evapotranspiration cools the air in the greenhouse. In this study, the energy model of lettuce is integrated to the greenhouse model developed to represent this impact (Talbot & Monfet, 2020).

Comparison Between Operating the Recovery System and the Propane Unit Heater

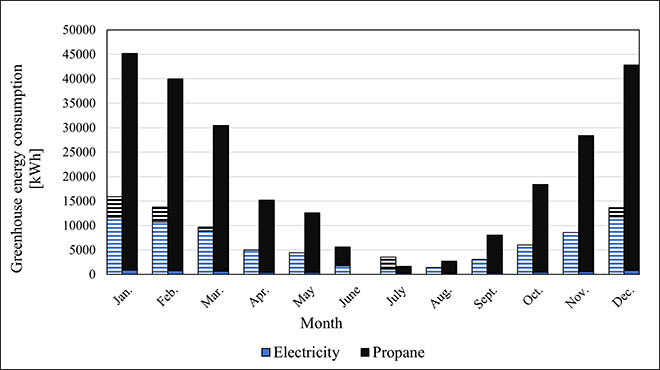

Figure 2 shows the monthly energy consumption per energy source associated with operating the two heating systems to maintain the greenhouse air temperature at 20 ℃ during the day and at 18 ℃ at night. In the developed model, the heat recovery system is considered unavailable during periods when peak load shaving of the data centre is required by the electricity supplier. These periods are characterized by outdoor temperatures below -15 ℃ during peak hours (6:00-9:00 a.m. and 6:00-8:00 p.m.). During these periods, the propane unit heater is used as a backup heating source.

Figure 2: Energy consumption of a greenhouse heated by a data centre heat recovery system (hatched) and a propane unit heater (solid)

Using the data centre heat recovery system reduces greenhouse energy consumption by 66% compared to using a propane unit heater. These reductions are achieved through the use of a heat pump to raise the temperature of the data centre’s exhaust air so that it can be used to heat the greenhouse. GHG emissions[1] are reduced by 91% by recovering waste heat from the data centre (31 kg eq. CO2/m2) compared to using a propane unit heater (348 kg eq. CO2/m2) to heat the greenhouse.

Other Considerations

Results of this comparative study have made it possible to evaluate the advantages of using data centre waste heat to heat a greenhouse in Quebec, compared to the usual heating approach using fossil fuels.

However, a financial analysis and a life cycle analysis (LCA) would provide a better evaluation of the investments and GHG emissions associated with installing all the equipment of a heat recovery system. This is worth studying since the proposed system is much more complex and still requires the installation of a backup heating system.

Moreover, heating greenhouses in winter in Quebec is not relevant if there is not enough light to ensure photosynthesis in plants. The energy impact of artificial lighting must be considered to evaluate the competitiveness of a winter greenhouse in the Quebec context (MAPAQ, 2018). A dynamic thermal simulation greenhouse model developed in the context of this study was also used to evaluate the energy consumption of a minimal artificial lighting system for photosynthesis in lettuce during winters in Baie-Comeau. A trade-off between heating and artificial lighting set points could be defined for lettuce to maximize the energy efficiency of the greenhouse (kg produced per kWh consumed).

For more information, please contact the authors.

[1] The emission factors used are 0.0345 kg eq. CO2/kWh for electricity (Levasseur, Mercier-Blais, Prairie, Tremblay, & Turpin, 2021) and 0.181 kg eq. CO2/kWh for propane (Eggleston, Buendia, Miwa, Ngara, & Tanabe, 2006).