Green hydrogen and the key role of membranes

To produce green hydrogen capable of powering fuel-cell cars already on the market—such as hydrogen models from Toyota, Hyundai, and BMW—proton exchange membrane water electrolyzers (PEMWEs) split water into hydrogen and oxygen using renewable electricity. These electrolyzers contain a thin polymer membrane that allows only protons to pass through while keeping the gases separate.

The challenge is that this membrane is both the electrolyzer’s core component and its weak link. Continuously exposed to chemical degradation, mechanical stress, and thermal cycling, it can thin, crack, or even perforate over time. In the worst cases, hydrogen and oxygen can mix, compromising safe operation and overall performance.

In industry, Nafion® 115 is the standard membrane thanks to its strong chemical stability. However, to make electrolyzers truly durable, its mechanical and thermal resistance must be improved without compromising electrochemical performance.

A thin graphene-oxide layer deposited by ultrasonic spraying

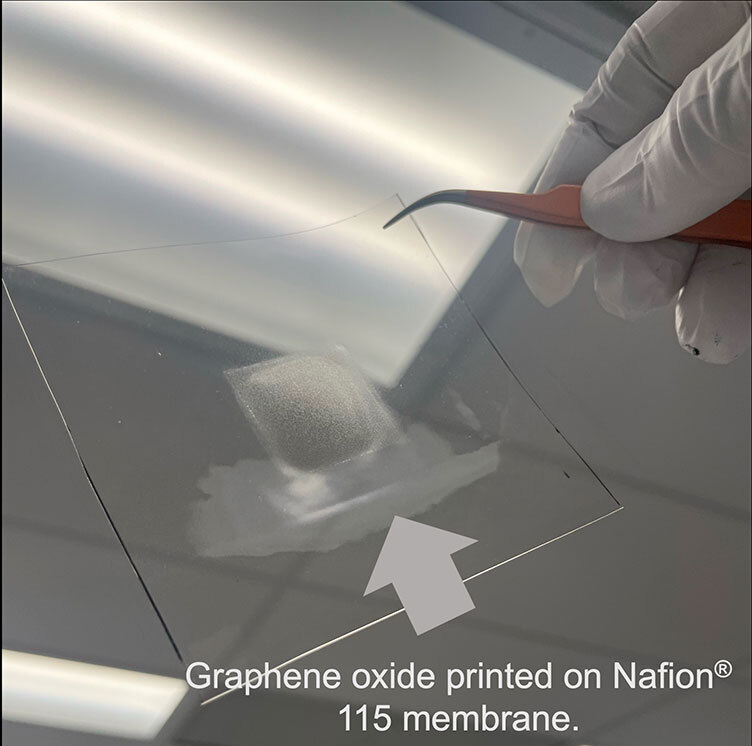

Instead of starting from scratch by developing a new membrane, the ÉTS research team and its partners opted for an approach more in line with industrial realities: starting with a commercially available Nafion® 115 membrane, and adding a thin composite layer of Nafion® and graphene oxide (GO).

Graphene oxide is derived from graphite, known for its high mechanical strength and exceptionally high surface area. It is primarily an electrical insulator, which is essential for a membrane that must conduct protons while blocking electron transport. Its surface, rich in oxygenated groups, also makes it highly hydrophilic.

We first formulated a stable Nafion-GO ink, then deposited it by ultrasonic spraying on one or both sides of the membrane, depending on the configuration being studied. This technique, widely used in industry for the manufacture of electrodes, offers precise control of thickness, producing a uniform layer about 20 µm thick, added to the Nafion® 115 membrane’s 127 µm thickness.

Rougher, more hydrophilic, and more resistant membranes

Once the composite layer was deposited, the membranes were heat-treated and characterized using various advanced techniques (AFM, SEM, PiFM, tensile testing, thermogravimetric analysis, etc.).

Observations show that adding GO makes the surface more textured and much rougher. This roughness increases the contact area between the membrane and the catalytic layer, which is conducive to electrochemical reactions.

Contact angle measurements also confirm that Nafion–GO membranes become more hydrophilic than pure Nafion®. This increased hydrophilicity is important because proton conduction depends on the presence of water in the membrane: the better the membrane retains water, the more efficiently protons can flow.

In mechanical terms, results are even more telling. Membranes containing GO could withstand significantly higher stresses and strains than the control samples. In some cases, tensile strength and elongation at break more than doubled. In other words, the reinforced membrane is much more resistant to stress without tearing.

Finally, thermogravimetric analyses show that degradation of the perfluorinated matrix begins at higher temperatures with GO. Depending on the processing conditions, the main decomposition temperature is shifted upward by about 30 °C, indicating improved thermal stability.

Maintaining electrochemical performance despite a thicker membrane

Reinforcing a membrane is beneficial, but it must not compromise the performance of the electrolyzer. However, increasing the thickness by 15% to 30% generally increases the resistance to proton transport.

To verify this, we tested the membranes in a PEM electrolyzer under realistic conditions (80 °C, up to 2 A·cm⁻²). Three configurations were compared to unmodified Nafion® 115:

- Nafion–GO layer on the cathode side;

- Nafion–GO layer on the anode side;

- Nafion–GO layer on both sides.

Key result: when the composite layer is deposited on the cathode side, the polarization curve is virtually identical to that of the original commercial membrane, despite the increase in thickness. The current density at 2.0 V is similar, and stability over 14 hours of testing is comparable.

However, when the layer is placed on the anode side or on both sides, performance drops by approximately 9% to 15%. As a result, the increased thickness and the modified anodic interface appear to hinder proton transport and reactions at the anode.

Towards more sustainable electrolyzers for green hydrogen

This study shows that it is possible to mechanically and thermally reinforce a Nafion® 115 membrane while maintaining electrochemical performance, provided that the Nafion–GO layer is correctly positioned on the cathode side.

Given the outlook for large-scale electrolysis plants—to power hydrogen buses, trains, or industrial processes—extending the life of membranes could reduce maintenance costs and improve system reliability.

The proposed approach has another advantage: it is based on an ultrasonic spraying technique already used in industry, and can therefore be easily integrated into existing processes. The next steps will be to further optimize ink formulation, layer thickness, and heat treatment conditions, as well as to conduct long-term durability tests.

In a nutshell, a handful of graphene oxide nanoflakes, well dispersed in the right layer and in the right place, can help make PEM electrolyzers more robust—and green hydrogen a little more accessible.

Additional Information

For more information on this research, please refer to the following paper: Ceballos-Alvarez C, Maziar J, Moradizadeh L, Siaj M, Shahgaldi S, Izquierdo R. Enhanced Graphene Oxide-Nafion® membranes for proton exchange membrane water electrolysis. Journal of Membrane Science. 2025 Oct;734:124267. doi: 10.1016/j.memsci.2025.124267.