General Information on Resin Printing

3D printing does not yet allow for the creation of all shapes and can sometimes be difficult to use in a production line.

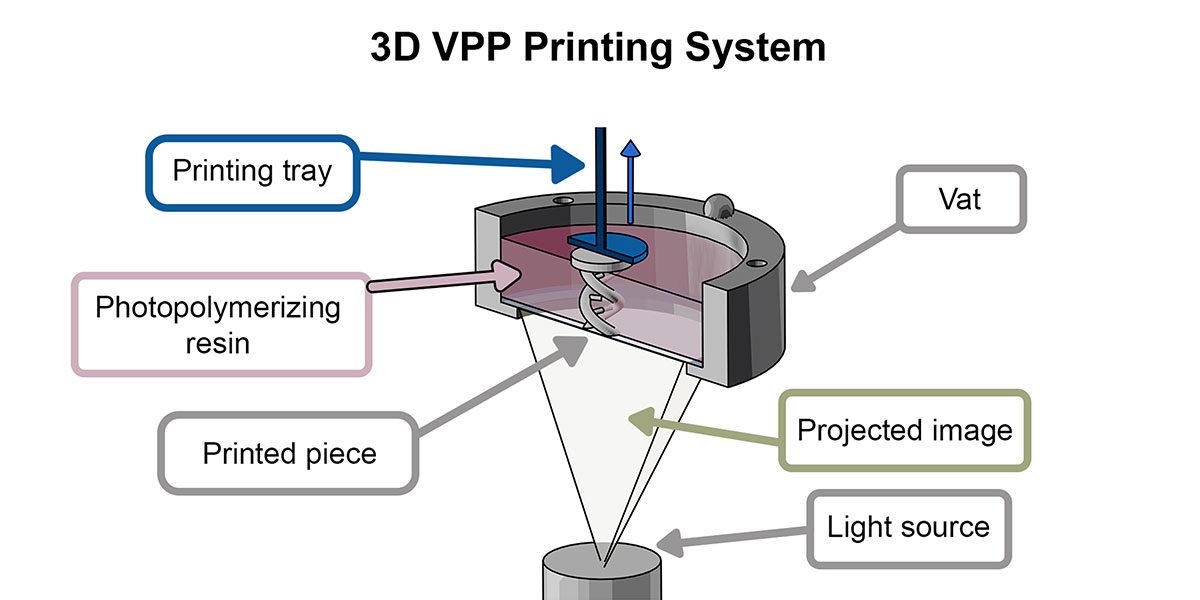

Liquid resin polymerization printing uses a resin bath with a transparent bottom, under which a light source is installed. A tray is placed in the resin and held at approximately 0.1 mm before the light source projects an image onto the bottom of the tank. This allows the resin to be selectively polymerized and form a solid resin layer with the desired shape. The tray is then raised by 0.1 mm and another image is projected. By repeating this movement in combination with image projections, a solid resin object with the desired shape is obtained. Finally, this object must be cleaned and then treated with ultraviolet light to complete the polymerization of the entire piece and prepare it for its final use.

Current Limitations of 3D Printing by Vat Photopolymerization

Not all objects can be printed using this method. The exclusively vertical movement of the platform limits the possibilities, namely due to gravity, which requires each polymerized layer to be attached to the previously solidified layer.

Its implementation in a production line is also hampered by the tasks that must be performed on the part before it can be of use. These include post-processing steps that require the part to be placed in other production cells, as well as the fact that the part is attached to the platform and must be removed with special care.

A New Approach: The Robotic Arm

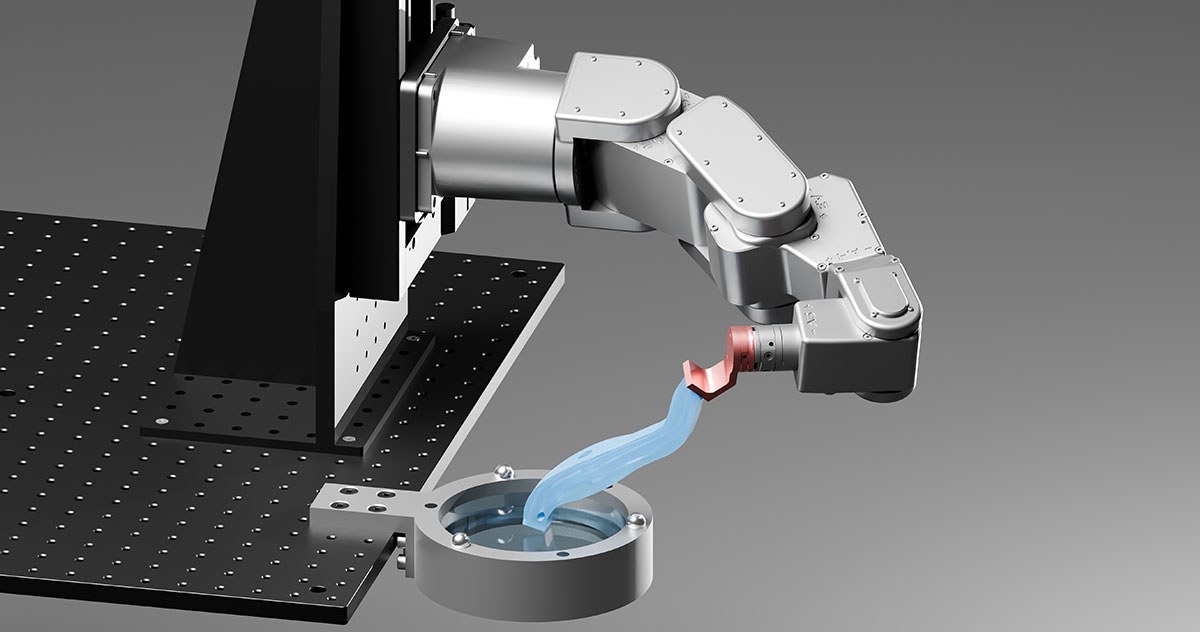

The solution described in this article involves the use of a robotic arm to which the printing plate is attached.

This increases the plate’s range of motion, making it easier to print more complex shapes. It also adds the ability to automate plate changes, enabling the continuous creation of parts without human intervention, in order to integrate this manufacturing process into a production line.

The main limitation that has prevented the use of a robotic arm until now is the accuracy of its spatial positioning. Indeed, all robotic arms are imperfect when they leave the factory. They are often highly repeatable—they can reposition themselves in the same place after a movement—but cannot accurately reach a defined target in space.

However, in the context of 3D printing, it is essential to be able to position the plate with the accuracy of around 0.1 mm (average height of the resin layers), otherwise the part will be distorted.

Robot Calibration

Fortunately, robot errors can be corrected by calibration. Calibrating a robot allows it to be modelled with its defects—axis offset, angular error in zero position, initial positioning error in the workshop, etc.—in order to improve its accuracy. Note that robot calibration must be repeated several times during use, as natural wear and tear on its components alters its geometry and therefore the positioning of its tool.

This step is comparable to the human body acquiring proprioception. Without knowing the exact length of each bone in our arm, if we know the angles of each joint (from the shoulder to the last phalanx), and we can see the position of our fingertips (through our eyes), by repeating the movement over and over again, we can generalize the geometry of our arm to the point where we can press a key on our keyboard without looking.

The same applies to a robotic arm, where the eye is replaced with an extremely accurate measuring instrument, and the fingertip corresponds to the robot’s tool. The idea is to measure the position of the tool for 50 to 100 different positions of the robot. On this basis, we can accurately identify the robot’s actual characteristics - segment lengths, joint angles, even deformations due to the weight of the robotic arm itself. This provides a realistic model of the robot, including its imperfections, and is then used to control it during the manufacturing process.

Calibration processes already exist, but are generally very expensive. For example, the most commonly used method requires measurements using a laser tracker, an instrument that costs over $100,000 and requires human intervention. And yet, it is important to calibrate the robot regularly to maintain its level of accuracy.

In this article, we propose a solution for calibrating a robotic arm using a more affordable method (~$5,000) that can be easily repeated without human assistance.

Additional Information

For more information on this research, please see the following paper:

Evan Rolland, Yasser Krim, Ahmed Joubair, Ilian A. Bonev, Evan Jones, Pengpeng Zhang, Cheng Sun, Nanzhu Zhao, Novel calibration method for robotic bottom-up vat polymerization additive manufacturing systems, Robotics and Computer-Integrated Manufacturing, Volume 97, 2026, 103059, ISSN 0736-5845.