The Industry 4.0 to Aerospace 4.0 Transition: How it’s Being Done

The featured image was bought on Istock.com. Copyrights.

Industry 4.0: History

The term “Industry 4.0” first appeared in 2010 as part of a strategic high-tech project prepared by Acatech, the German Academy of Science and Engineering, at the request of the German government. The purpose of this project was to promote computerization in the manufacturing industry [1].

Unlike other industrialized countries, Germany has managed, over the past decade, to stabilize employment in the production sector, despite higher wages. Due notably to its medium-sized but highly innovative manufacturing industry, this country has had better control than many others over the economic impacts of the financial crisis [2]. Germany wanted to play a key role in implementing the fourth manufacturing revolution, Industry 4.0. The project was first presented to the public in 2011 at the Hanover Trade Fair, the world’s largest industrial technology exhibition.

On April 8, 2013, at the suggestion of the Federal Ministry of Education and Research (BMBF), Acatech presented the final project report at the Hanover Fair, which became the Industry 4.0 platform and included recommendations for its implementation as well as the associated research program [3].

Industry 4.0 in 100 Countries Worldwide

On January 12, 2018, the World Economic Forum published the first issue of a report describing the readiness of countries around the world [4]:

[This report] evaluates the readiness of 100 countries for the future of production based on 59 indicators covering two main components: the structure of production and the drivers of production. The global benchmark and related analysis presented in this report are intended to highlight the development of modern industrial strategies by showing strengths, weaknesses, trends and opportunities linked to the changing nature of production.

(Source : http://www3.weforum.org/docs/FOP_Readiness_Report_2018.pdf – pp. 3, 11)

World Economic Forum

The top 25 countries most ready to transition to Industry 4.0 are (in alphabetical order): Austria, Belgium, Canada, China, Czech Republic, Denmark, Estonia, Finland, France, Germany, Ireland, Israel, Italy, Japan, Malaysia, Netherlands, Poland, Republic of Korea, Singapore, Slovenia, Spain, Sweden, Switzerland, the United Kingdom and the United States.

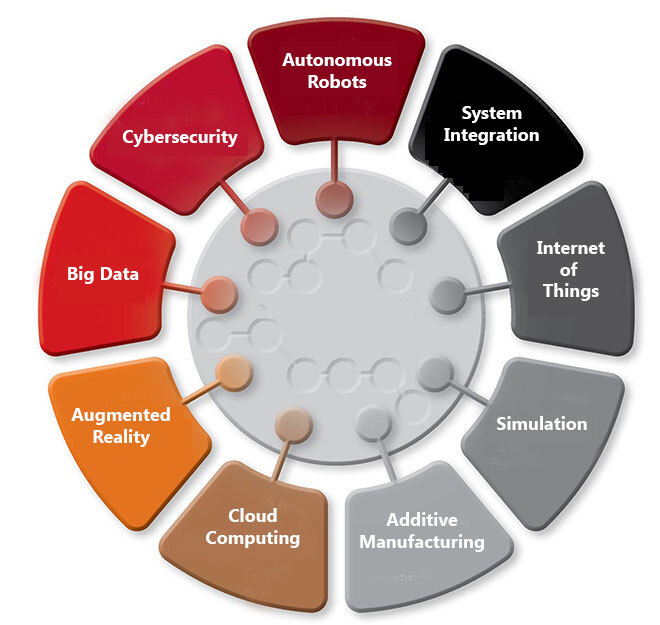

Industry 4.0: Nine Related Technologies

Industry 4.0 encompasses nine technologies that combine to revolutionize manufacturing production.

A description of these technologies is provided in the article “Aerospace 4.0: The Fourth Industrial Revolution Applied to Aerospace,” published on Substance, February 27, 2018.

New Skills Required

Implementing these nine new technologies will oblige many companies to train their employees, technicians and engineers. According to a study by the MMB Institute, about 30% of German businesses believe that their employees do not have the proper skills to successfully transition to Industry 4.0 [5]. Since 2015, the MMB Institute has completed 26 studies, analyses and research reports on the required skills. These skills have been classified into four categories:

- Technical skills: basic and specialized skills.

- Computer and analytical skills, data management: skills linked to management, use and verification of data-driven systems, including analysis, security and protection of data.

- Social skills: interdisciplinary cooperation, project management, communication skills, organizational and leadership skills, decision-making skills.

- Personal skills: self-learning skills, analytical thought, problem solving, abstract thought, openness, flexibility.

Aerospace 4.0™

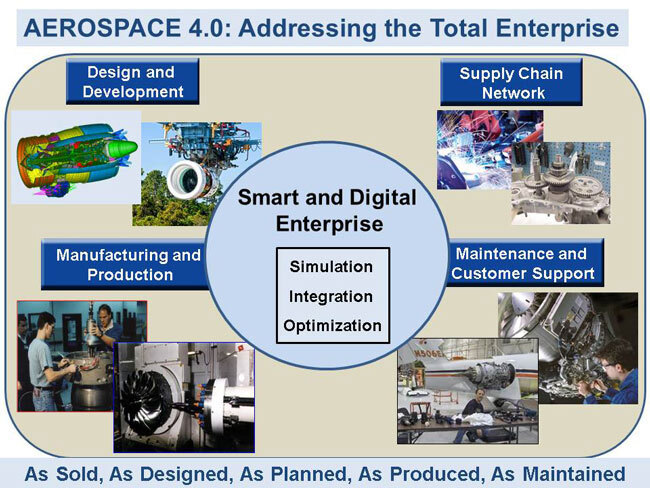

In 2016, the AÉROÉTS group at the École de technologie supérieure (ÉTS) of Montréal created an integrated research and teaching program called Aerospace 4.0™. The objective of the program is to support Canadian aerospace industry businesses in the transition to Industry 4.0 technologies. Aerospace 4.0TM is not only focus on factories and production, it addresses the entire business, from design to customer service, including supply chain, development, manufacturing, production, and maintenance [6].

Lately, Quebec media have been giving more attention to the issues surrounding “Industry 4.0”, but ÉTS professors have been conducting research in the technological areas associated with this topic for many years. For example, the NUMÉRIX laboratory, launched in 2013, brings together a dozen experts who focus on sustainable supply and value chain engineering, integrated digital enterprises and enterprise engineering for innovation.

In addition, launching the Aerospace 4.0TM program in 2016 made it possible for ÉTS to involve a greater number of stakeholders in developing an integrated approach to research and teaching specific to the challenges of the aerospace industry.

Over the last two years, several companies in the sector have been contacted to better define their needs and develop new research collaborations. These steps have proven fruitful, namely through the launch of four key projects.

Aero 4.0 Performance Indicators

In collaboration with Hamburg Aviation (Germany) and the Aéro Montréal cluster, this project will define Aerospace 4.0 performance indicators based on eight elements:

- multidisciplinary design optimization,

- simulation and test data management,

- multidisciplinary factory optimization,

- product development process,

- enterprise resource planning,

- customer relationship management,

- supply chain management,

- product lifecycle management.

MACH FAB 4.0

This project, led by the Aéro Montréal industrial cluster, will raise Quebec SMEs’ awareness of the realities of the fourth industrial revolution. MACH FAB 4.0 will conduct a diagnosis of the technological maturity level of participating SMEs in relation to 4.0 technologies, allowing the leaders to develop an action plan to meet the challenges of transitioning to 4.0.

Research Project with Siemens

An ambitious research program with Siemens is being launched in 2018. It will involve some twenty professors from ÉTS, Concordia University and McGill University over the next five years. The three main subjects will be:

- Digital multidisciplinary analysis and design optimization

- Advanced manufacturing automation, digitization and optimization

- A digital technology platform for supply chain.

Aside from these 3 projects, discussions are ongoing with various companies interested in the expertise of ÉTS, including Pratt & Whitney and Bombardier.

Aerospace 4.0 Training

New short-term training sessions are offered in the spring of 2018 for engineers and professionals who wish to learn more about the Aerospace 4.0 subjects, through the Centre for Aerospace Professional Education (a collaboration between ÉTS and McGill University). Other academic initiatives will be announced in the coming months.