How can aerial exploration unfold in underground or cluttered environments where drones struggle to navigate, and humans cannot safely reach?

This question prompted research in the design and fabrication of a robust yet ultra-light membrane, allowing lighter-than-air vehicles to move safely among obstacles while carrying useful payloads in confined spaces. How delicate polymer films can remain flexible, repairable, and responsive even under mechanical stress was explored through a process combining materials experimentation, structural analysis, and iterative fabrication.

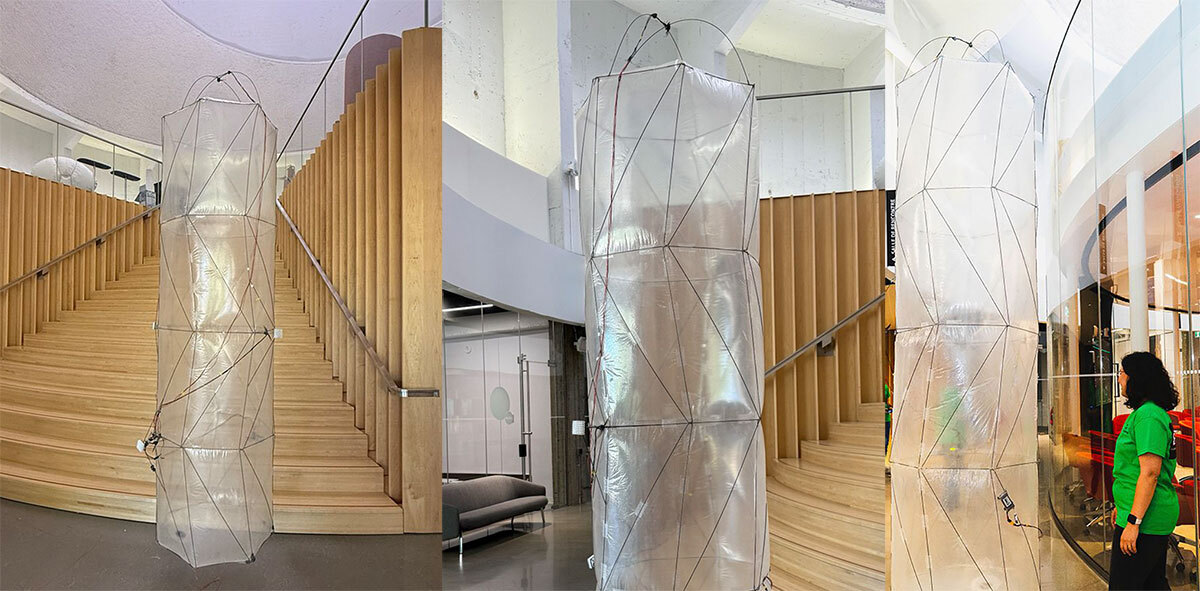

The resulting prototype (a helium-filled indoor airship) was tested in Montréal’s Saint-Léonard Cave on September 2024, where its flexible, translucent envelope reacted to air currents, humidity, and pressure with subtle pulsations. Inside this environment, engineering function and aesthetic perception merge: structural resilience becomes a visible rhythm, and the physics of buoyancy takes on the quiet cadence of breath.

Project Description

Just as centuries of flight have been devoted to mastering the skies, there was a parallel need to explore the vast, overlooked spaces beneath, underground cavities and architectural interiors where air, gravity, and light behave differently. To navigate safely in these delicate environments, flight had to become gentler, slower, and more adaptive, carried by materials capable of withstanding contact and compression rather than resisting them.

Outdoor aerostats are designed to resist wind loads, ultraviolet radiation, and large thermal gradients; they prioritize aerodynamic stability, weather resistance, and heavy payload capacities. Indoor and underground missions, by contrast, demand a radically different approach. They unfold in confined, GPS-denied environments where walls, stalactites, and narrow passages leave little margin for collision. In these conditions, safety and maneuverability outweigh aerodynamic efficiency. Designs must emphasize extreme lightness, responsive control, and impact tolerance, while operating within strict mass constraints that limit payload capacity. Typical applications include mapping, inspection, and human-robot interaction in architectural and natural interiors, where propeller-based drones often fail.

These environmental, structural, and operational constraints became the foundation for a new line of inquiry: how to create an ultra-light, airtight, airship envelope that is resilient enough to enable delicate autonomous flight in subterranean or industrial environments. Existing materials on the market or commercial films, such as polyurethane (PU) and Mylar, proved too stiff, too heavy, or too gas-permeable for such conditions. The challenge called for genuine material innovation.

Developing an Ultra-Light Membrane

This pursuit led to the creation of a novel ultra-light polymer film-based membrane with a tailored sol-gel coating, developed under the project name VELUM (Vehicle Envelope with Lightweight Ultrafilm for Minimal Leakage) and now protected by a patent application filed by ÉTS. The objective was to maintain the flexibility and foldability of thin polyethylene while significantly improving helium retention and surface durability.

To understand its behavior, the material was examined through a complete series of laboratory experiments. Each test addressed a specific question about flight feasibility and how its key behaviors differed from those of conventional materials available on the market:

- How strong is it? Tensile, puncture and tear tests stretched the films until rupture, revealing how each material—polymer film, polyurethane (PU), and Mylar—failed differently. The polymer film elongated smoothly before tearing, while PU and Mylar broke abruptly, showing their rigidity and brittleness.

- How does it react to internal pressure? Burst experiments involved inflating small, sealed cushions until they exploded. These tests mimicked the stresses experienced by a flying airship and confirmed that the new film could tolerate high surface tension without losing its flexibility.

- Can it retain its gas? Long-term leakage tests compared helium loss through the three films. The coated polymer film retained its volume much longer than PU, proving that its barrier coating was effectively sealing microscopic pores in the base polymer.

- Can it withstand handling and folding? Durability experiments mimicked the repeated actions of packaging, transporting, and reinflating an airship. While Mylar often creased permanently and PU layers stuck together under moisture, the coated polymer film recovered its form after multiple cycles.

- How does its surface interact with water? Observation of droplets on the surface revealed that the coating maintained a high contact angle, with water beading rather than spreading, demonstrating that the membrane would resist humidity and condensation in damp environments such as caves.

Together, these observations revealed not only the mechanical strength but also the material personality of the coated polymer film: soft yet strong, transparent yet protective. It combined the lightness required for controlled indoor flight with the resilience necessary for repeated use.

Compared to traditional outdoor envelope materials, which are often thick, rigid, and over-engineered for indoor conditions, this new film offered a balanced compromise, easy to handle, quick to repair, and visually unobtrusive when inflated.

From the Laboratory to the Field

Following extensive laboratory validation, the newly developed membrane was integrated into a functional airship prototype for field testing. This phase aimed to evaluate how the material’s properties, flexibility, gas retention, and resilience would perform under real environmental conditions.

Under such conditions, traditional drones quickly reach their limits: propeller turbulence disperses dust and droplets, short battery life restricts endurance, and GPS signals are nonexistent. The lighter-than-air solution offered by the Cavernautes system—built around the new membrane—enabled silent, stable, long-lasting, and low-impact flight above the river surface, safely maintaining altitude through internal pressure regulation and a lightweight control system designed specifically for LTA navigation. The envelope’s soft, flexible skin allowed gentle contact with the cave walls without damage, while its improved helium retention ensured multi-hour flight stability.

The mission demonstrated not only the material’s technical success but also its aesthetic and experiential dimensions. Under headlamps and the cave’s faint reflections, the semi-transparent film revealed layers of wrinkling and pulsation as internal pressure fluctuated with temperature and motion. These living, breathing patterns visually echoed the physical processes of the cave itself, the air, humidity, and time, turning the engineering experiment into a sensory encounter.

Beyond cave exploration, this membrane technology paves the way for new kinds of indoor aerial systems for inspection, documentation, and human-robot interaction, where minimal energy, low noise, and soft contact are essential. It represents a practical step toward sustainable, context-aware flight, an achievement rooted in empirical mechanics but open to artistic interpretation.

Acknowledgements

This project was carried out at the INIT Robots LaboratoryÉcole de Technologie Supérieure (ÉTS), under the supervision of Professors David St-Onge and Ilyass Tabiai (LIPEC Lab). It was supported by the Fonds de recherche du Québec – Nature et technologies (FRQNT, Team Grant #283381) and developed in collaboration with NXI Gestatio(Professor Nicolas Reeves) at UQAM, as part of a research-creation initiative in the arts. The author would also like to thank the Cavernautes research group.

For More Information