The Shortcomings of Isolated Industrial Robots

In modern manufacturing, robotic arms have become the backbone of several production pipelines. However, most industrial robots currently operate in isolation; one robot is permanently assigned to one limited task (i.e. single machine tending). In the context of batch-one, customizable production pipelines, this setup is not flexible enough; if a machine finishes its task early, the robot sits idle, and if a robot breaks down, that entire production line stops.

While researchers have tried to use teams of mobile robots to address this, most current systems rely on a central management unit to tell each robot where to go and what to do. This creates a single point of failure: if the central server goes down, the entire factory floor freezes. To build a truly resilient and adaptive factory, we need robots that can think for themselves and adapt to changes dynamically.

Decentralized Learning for Cooperative Robot Swarms

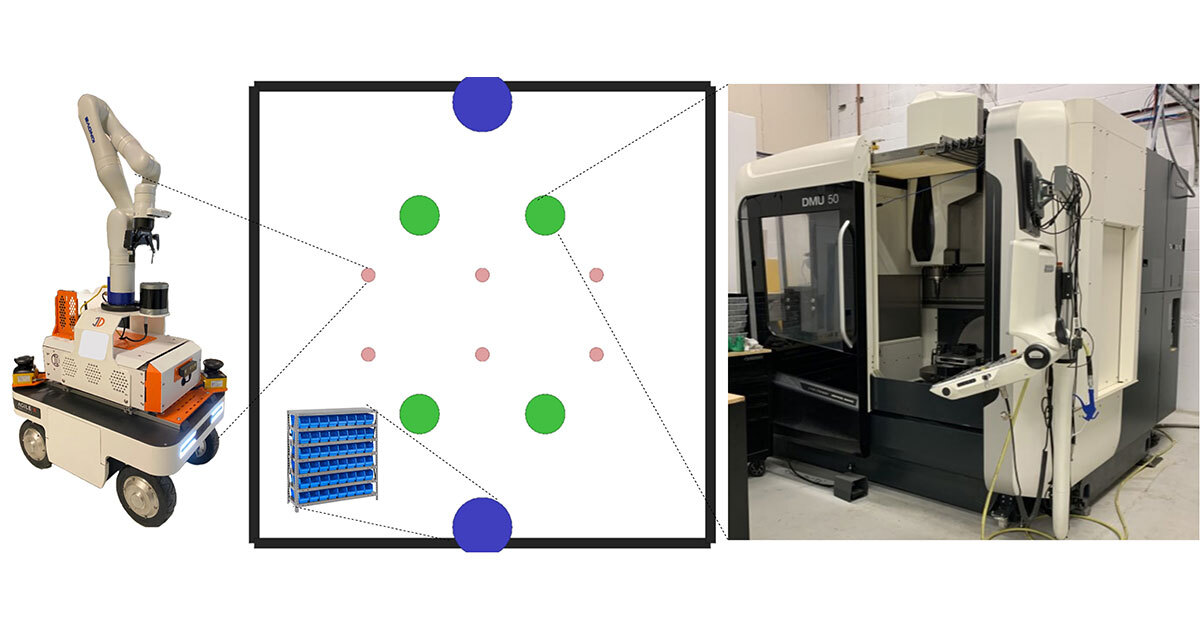

Our recent works (AB-MAPPO [1] and SMAPPO [2]) explored using AI to enable decentralized multi-robot task assignment and navigation. This means that in a factory setting, a swarm of mobile manipulators (unmanned ground vehicles with robotic arms) can attend to multiple production machines. Each robot makes its own independent decisions based on its observation of the factory, on which machine to go to and how, to take a ready part, and where to drop it.

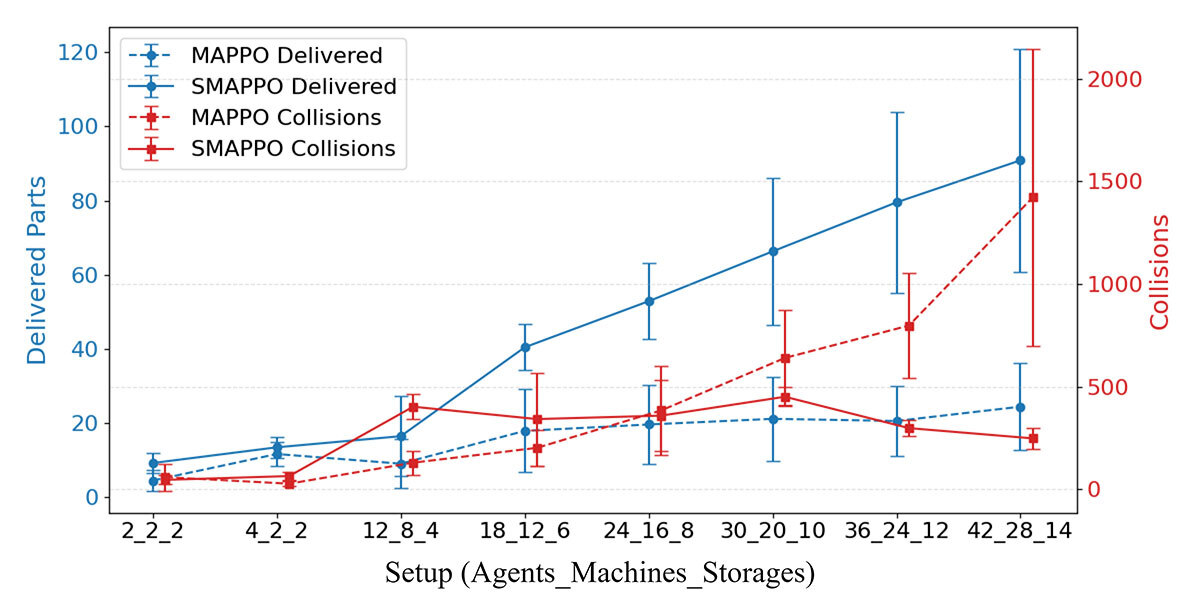

AB-MAPPO uses an interactive learning technique called MARL, a process where a group of AI agents learn through interaction with their environment, receiving rewards for delivering parts and penalties for colliding with walls or teammates. Up to now, learned models have been largely limited to unrealistic simulation and toy problems. The lack of realism was often related to assumptions made to simplify the model's observations of the world. Our work (AB-MAPPO) first introduced a novel information encoder based on an AI technique called "multi-head attention" that helps a system focus on the most important parts of the information it observes, much like humans pay attention to what matters most and ignore the rest. Extensive evaluations showed that with this addition, the model not only addresses the problem but also achieves more deliveries and better resource utilization, while still being safer than the state-of-the-art multi-agent learning technique (MAPPO).

One Learning Framework for Any Factory Size

However, scalability to different fleet scales was not robust enough. Our work (SMAPPO) introduces a significant breakthrough with an input-size invariant model. Previously, if you trained an AI to operate in a factory with five machines and then added a sixth, the trained model would "break" because the amount of incoming data changed. This meant spending weeks retraining the system from scratch. SMAPPO developed a novel observation encoder that allows it to handle any number of robots, machines, or storage areas without needing to be retrained, while remaining decentralized.

To achieve this flexibility, instead of trying to memorize the entire factory floor, the SMAPPO encoder groups objects by type: "fellow robots," "production machines," and "storage zones". The system uses a separate encoder for each entity type, where the encoder learns to focus only on the most relevant information in that group and summarize it into a fixed-size representation regardless of the number of members in the group. The system then combines these concise mental maps to make informed decisions. This allows the robot to maintain a fixed-size overall mental map, regardless of how many robots, machines, or storage areas are in the room.

To demonstrate the potential of these contributions, the researchers optimized a high-speed simulator (VMAS) to run complex scenarios with up to 100 robots at a time. Compared to MAPPO, SMAPPO showed massive productivity gains: an increase in part delivery of up to 61% in the large-scale scenario. In addition to unmatched scalability, in zero-shot tests where the model was placed in significantly larger-scale scenarios that it had never seen before, SMAPPO performed almost 4 times the deliveries made by the default MAPPO. On top of that, SMAPPO exhibited superior safety, with fewer than one-fifth of the collisions observed with MAPPO, which would correspond to significantly fewer safety-stop activations in real-world deployment.

Toward Flexible, Safe, and Truly Adaptive Smart Factories

This research takes AI beyond simple toy problems (like StarCraft or digital soccer) and into realistic, industry-oriented scenarios. Because SMAPPO can scale up or down instantly, it allows a factory to grow or shrink based on market demand without expensive reprogramming. By creating robots that are both independent and collaborative, this work paves the way for a future where a swarm of autonomous assistants can navigate a busy factory floor, delivering materials and managing tasks as naturally as a team of human experts.

References

[1] Abdalwhab, A. B. M., Beltrame, G., Kahou, S. E. & St-Onge, D. (2025). Attention-Based Multi-Agent RL for Multi-Machine Tending Using Mobile Robots. AI, 6(10). doi: 10.3390/ai6100252.

[2] Abdalwhab, A. B. M., Beltrame, G. & St-Onge, D. (2026). Scalable Multi-Agent Reinforcement Learning Framework for Multi-Machine Tending. IEEE Robotics and Automation 11(3), pp. 3135-3142. doi: 10.1109/LRA.2026.3655200.