Protecting Parts Where They Are Most Stressed

Modern mechanical parts are subjected to increasingly complex environments. In addition to achieving lighter structures, they must also withstand increasing mechanical stresses. These parts often fail due to fatigue caused by repeated and varying stresses, with cracks appearing on the surface where stress is at its peak.

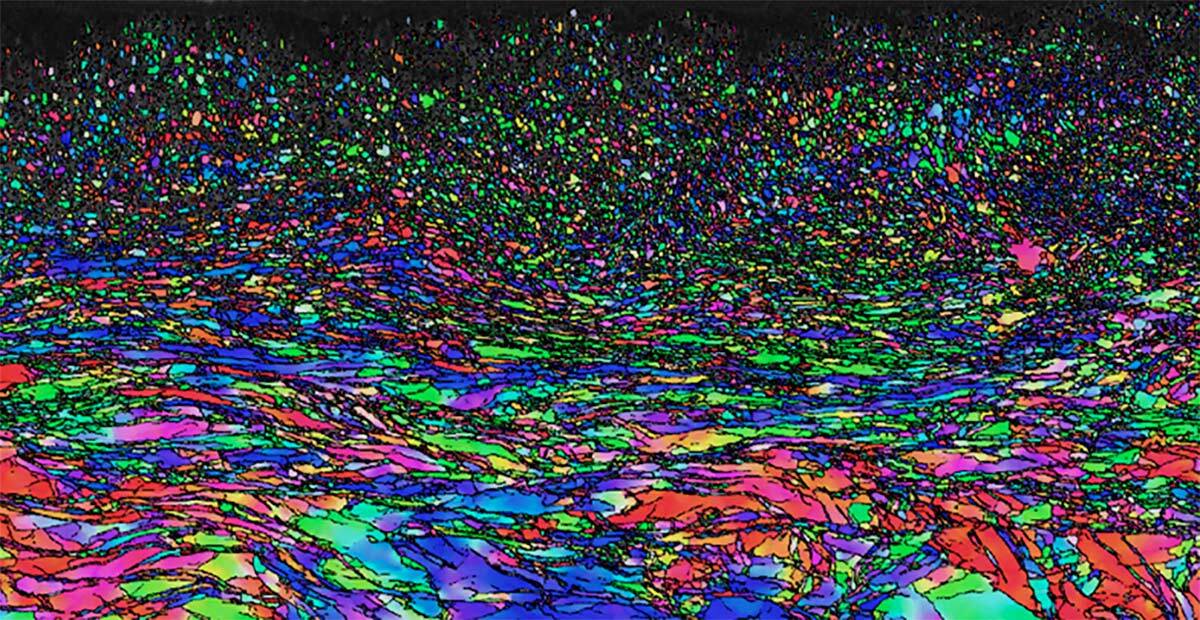

To improve fatigue resistance, an effective method is to strengthen the material's surface using ultrasonic shot peening. This technique involves propelling spinning beads using an ultrasonic frequency vibrating base in a closed chamber. This treatment, derived from conventional shot peening, induces significant plastic deformation on the surface, causing work hardening of the microstructure and generating residual compressive stresses, known to delay the onset and propagation of cracks. This improves surface properties while maintaining good ductility at the core of the material.

However, modern materials, which are often stronger and less ductile, are more difficult to deform, which can lead to cracks or defects during processing. This is where temperature becomes a promising avenue: by modifying the shot peening temperature, it is possible to facilitate plastic deformation, activate different deformation mechanisms, and form new microstructures on surfaces with new mechanical properties.

But what exactly is the role of temperature in this process? And how can it be used to adapt the material's performance to the growing demands of industrial applications? The objective of our study was to answer these questions by exploring the effect of ultrasonic shot peening at different temperatures on 316L austenitic stainless steel. However, this material, widely used for its corrosion resistance, has limited mechanical properties, which can be improved through work hardening, i.e., hardening resulting from plastic deformation that modifies the material's microstructure. This makes 316L an ideal candidate for shot peening.

Deformation Mechanisms that Evolve with Temperature

Temperature has a significant influence on the deformation of a metal, specifically by altering its stacking fault energy, an essential property that controls the deformation mechanisms activated in 316L stainless steel.

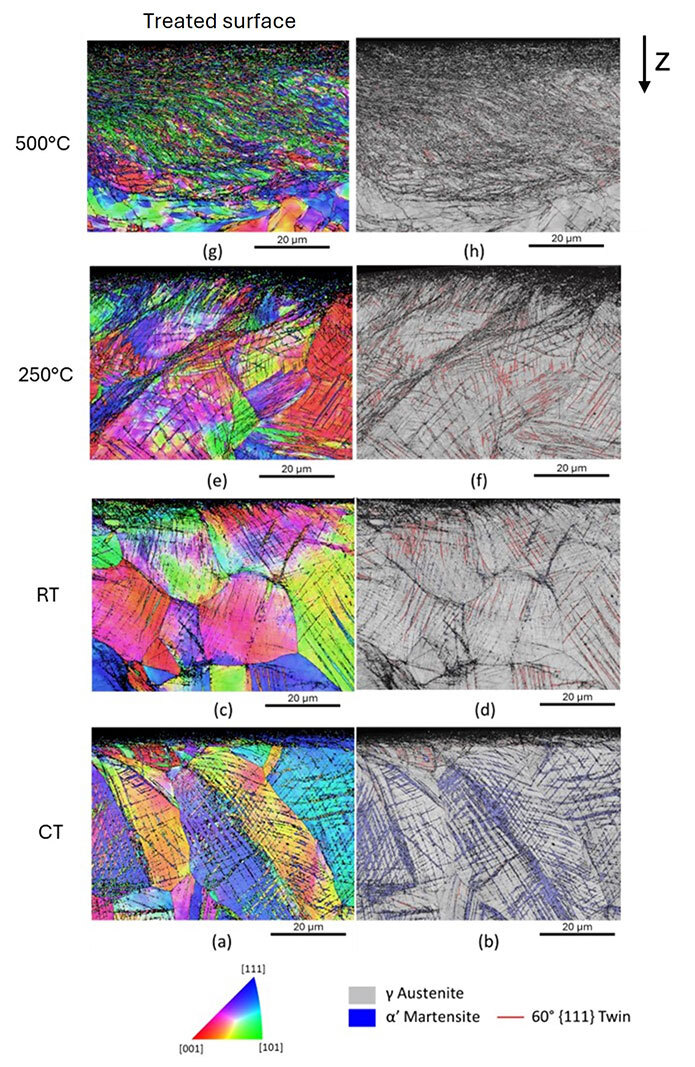

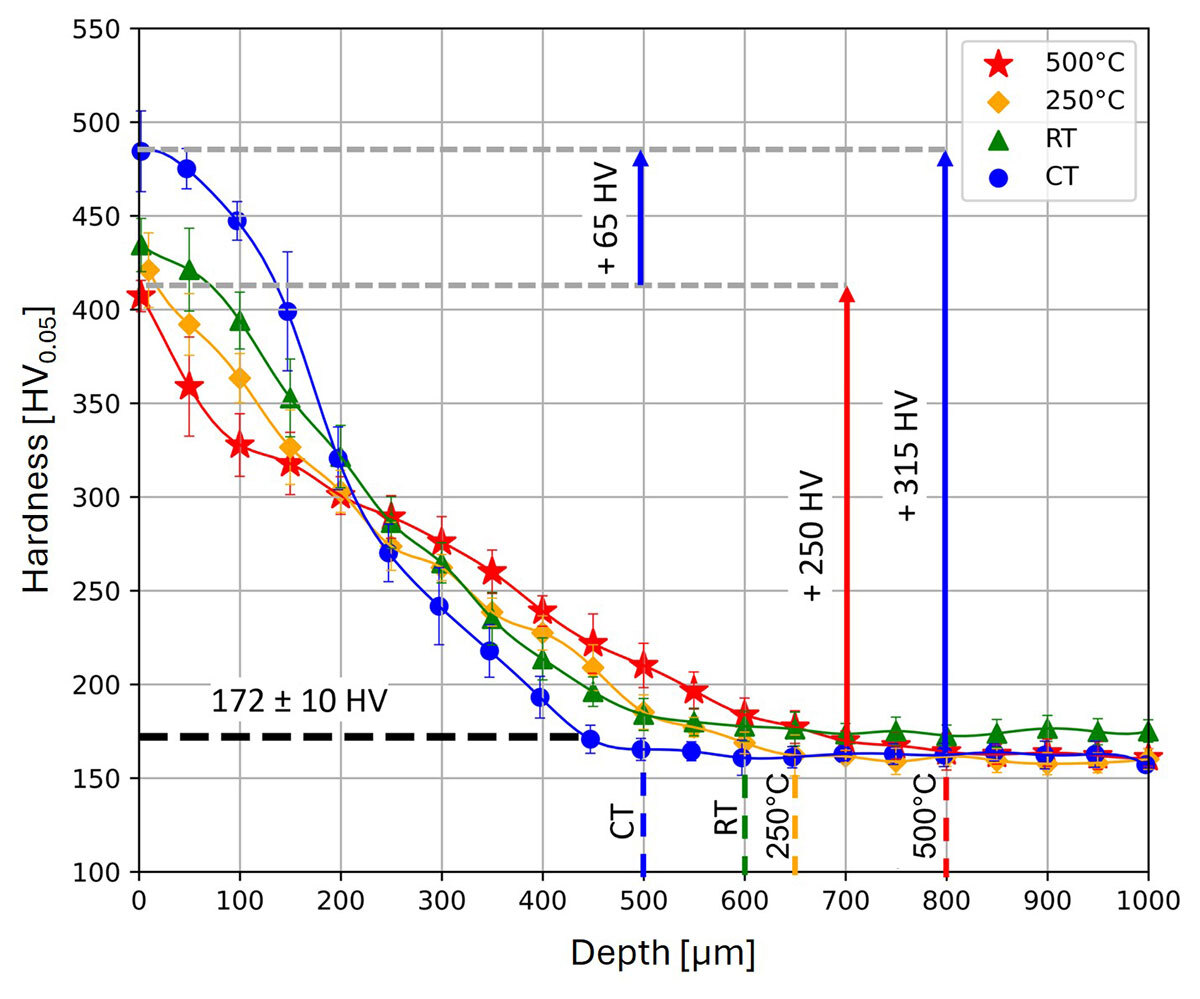

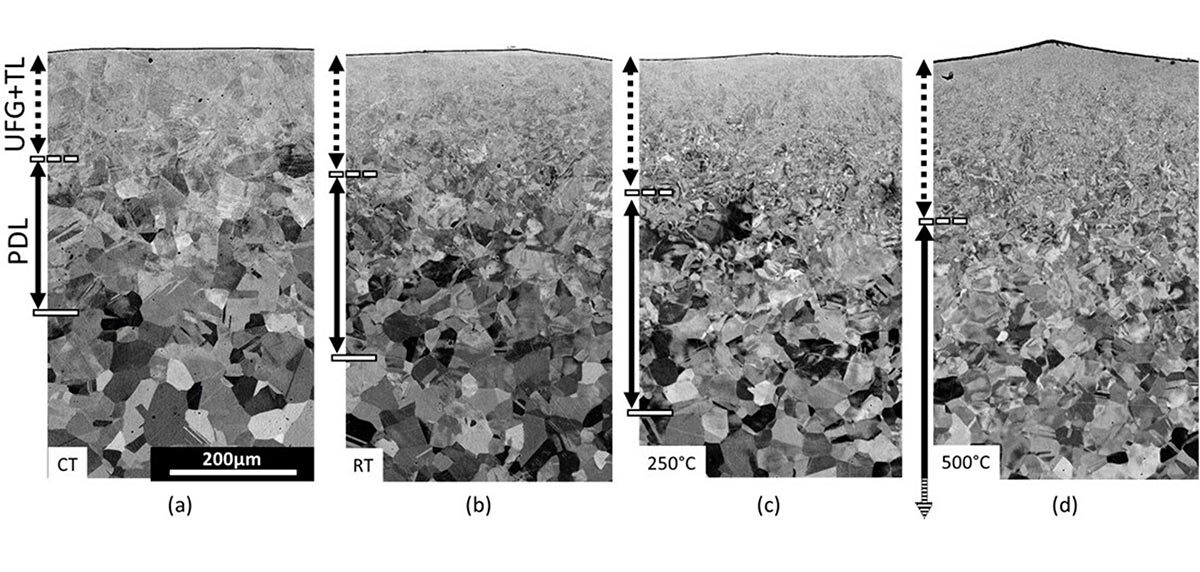

At ambient temperature, this energy is relatively low. The steel then deforms mainly through the formation of defects called twinning. This results in increased hardness and the appearance of compressive stresses on the surface. However, these effects remain limited in depth.

At very low temperatures (-130°C), the stacking fault energy decreases even further, activating another mechanism: martensitic transformation, a phase change in the crystal structure. This phenomenon causes a significant rise in surface hardness and an increase in residual compressive stresses at the expense of the affected depth.

When shot peening is performed at high temperatures (500°C), the stacking fault energy of the material increases and dislocations—crystalline defects responsible for the plasticity of the metal—become more mobile. Under the combined effect of temperature and deformation, these dislocations slide, interact, and reorganize, a phenomenon known as dynamic recrystallization. This process leads to the formation of a new, more stable microstructure with fewer defects.

This reduces surface hardening but significantly increases the depth affected by the process. Indeed, at this temperature, the material's yield strength decreases, making it easier to deeply deform under impact.

Adapting Material Performance to Its Use

This study shows that by adjusting the temperature during ultrasonic shot peening, it is possible to customize the properties of the material. Cryogenic (cold) treatment is ideal for increasing surface hardness on thin sections, which is useful for parts subject to wear. Conversely, heat treatment promotes deep mechanical strengthening, with the formation of a more stable recrystallized microstructure, potentially better suited to fatigue stresses and offering greater resistance to cumulative damage.

Conclusion

Temperature is a key parameter for controlling the effects of ultrasonic shot peening on 316L stainless steel. Acting on the activated deformation mechanisms makes it possible to modulate the microstructure, hardness, and residual compressive stresses of the material. This method opens up new prospects for surface engineering, particularly in demanding sectors such as aeronautics, biomedicine and energy.

Additional Information

For more information on this research, please refer to the following article:

Yann Austernaud, Marc Novelli, Philippe Bocher, Thierry Grosdidier, Effect of shot peening temperature on the microstructure induced by surface severe plastic deformation on an austenitic stainless steel, Journal of Materials Processing Technology, Volume 339, 2025, 118823, ISSN 0924-0136,