AI-Enhance Terahertz Imaging for Flexible Electronics

Purchased from Gettyimages. Copyright.

Today we train our fingers to design our future on a flexible caricature… Catch a dream up on the horizon and stretch it over the fabric of time”

Stretching it into the Future

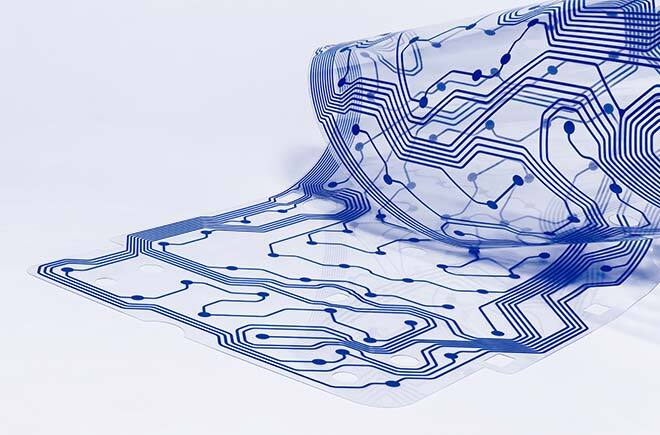

We live in a world steered by electronics. From analog to digital, from DOS to Windows, from iPhone to iPhone 14 Pro Max, we are witnessing an era of rapid electronics evolution. To keep up with increasing demand, researchers are manoeuvring their way to more convenient and efficient electronics. Printable flexible electronics (PE) are a lighter alternative to today’s electronic devices, while more economical, environmentally friendly, intelligent, power-efficient, robust, thin, and flexible. Printable electronics are circuits printed on a substrate (plastic, skin, fabric, etc.) using metallic ink. In addition to being highly flexible and lightweight, these devices have the added advantage of allowing mass production at lesser costs. From floating screens to memory implants, the future offered by printed flexible electronics is nothing less than a sci-fi fantasy.

The Lighter the Better

Technological advances in the field of medicine and surgery, consumer electronics, energy power, aerospace, healthcare, space and communication, military, etc., demand high-performing electronics with negligible weight.

Did you know, the flexible electronics market will be worth over 61B US$ by 2030?

Flexible electronics is a competitive landscape where leading manufacturers are investing in R&D for innovative products to strengthen their market position. Ever since the inception of printable electronics, its market has been growing with an annual rate of 11.8%, as reported in 2022. With products ranging from paper supercapacitors to COVID test strips and electronic printed fabrics, 2022 alone witnessed an avalanche of innovative printed flexible electronic products.

It is all Good as Gold. So what is the Problem?

The main challenge faced by printed flexible electronics is quality control. Size reduction comes at a cost relating to carrier mobility fluctuations along with temperature, carrier leaking, low noise margin, etc. The resolution of most printing processes is now between 5μm‒100μm. Increasing printing resolution while keeping parameters within optimal ranges is a technical challenge. The change in conductivity induced by bending or twisting materials should also be tracked for performance analysis.

We Have the Solution in just in One Click!

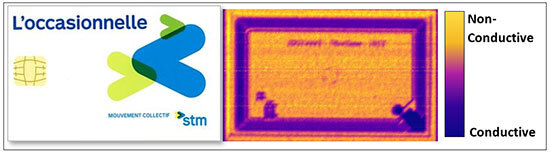

Terahertz (THz)—a frequency sandwiched between the microwave and infrared regions of the electromagnetic spectrum—can induce and probe changes in the electrical properties of matter. Therefore, THz imaging is an efficient technique in imaging the electrical properties of matter. This technique can be used for the characterization of PE. Our research group successfully developed an innovative THz source [1] as well as THz imaging techniques [2, 3]. Detection of conductivity for quality control using non-contact methods is much needed in printed flexible electronics. The first non-destructive contactless quality control technique using THz Time Domain Spectroscopy (THz-TDS) [4] was reported by our research group in 2019.

Figure 1: Visible and THz images of a transport ticket. The conductive printed circuit and the non-conductive paper is well mapped using THz. And, have you noticed the chip on the left edge is fake?

The advent of AI and IoT has revolutionized every field of research and development. With the help of deep learning algorithms, we are developing technologies that could revolutionize printable electronics production. We obtained THz images of various PE samples under different environments by using our new THz imaging techniques. We are developing machine learning models that can predict the quality of a sample and its parameters including conductivity, carrier mobility, temperature tolerance, and printing accuracy just by looking at its image! Deep CNN-based models using a few parameters can allow mapping the resulting THz image to its targeted design and detect printing variations. Real-time variation detection can be done by training a regression model to identify defects directly from captured raw images through a multilayer architecture. Feature extraction and feature matching steps are integrated into the same architecture for faster performance. Moreover, a quality prediction architecture built on target designs can help in reducing production costs by minimizing waste.

Here at TeraÉTS, we expect that our new research will celebrate the advent of future printed flexible electronics.