Abstract

Walk into a modern factory and you’ll see the future of work in action: operators wearing smart glasses and gloves that guide their hands, and sensors connecting equipment/tools/humans on an assembly line. This is the promise of Industry 5.0, a world of greater precision, faster results and fewer errors.

But behind this promise lies a critical challenge. With every new device, we introduce a new layer of complexity. How do we ensure these technologies support and empower workers, instead of quietly creating new risks (including occupational health and safety)?

This is the question driving our research. We found that the traditional risk assessment tools wouldn’t be enough. So we improved qualitative risk assessment approaches to emerging complex systems, and proposed a new class of hybrid and quantitative tools to manage risk in these complex environments, especially where people and smart technologies interact. We developed prototypes and tested STPA-PSO and FRAM-PSO across three realistic case studies in industrial assembly and disassembly.

What we’ve discovered is that it’s possible to design a safe system from the ground up—and that smarter risk management goes hand-in-hand with sustainability.

Hybrid Tools for Hybrid Workplaces!

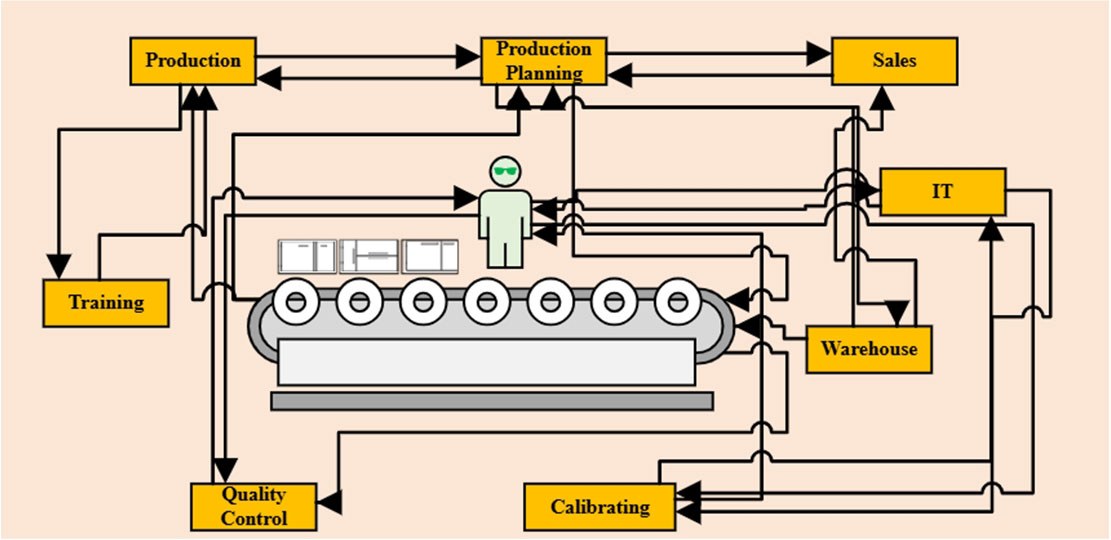

Smart wearables, like data glasses or sensor gloves, are becoming increasingly common in manufacturing. They guide workers, gather data and facilitate the manufacturing process. But they also add complexity. If a device delays, distracts, or confuses, the consequences can ripple through the entire production system and have negative impacts on workers.

The problem is, traditional risk assessment tools were never built for this. They excel at analyzing mechanical failures or isolated events, not in the complex, dynamic interactions between people, machines, tools, software, instructions and the environment.

This is where our hybrid and quantitative prototype tools come in. We created our risk assessment prototype tools by blending human insight with the analytical power of AI to give us a much deeper understanding of workplace risks. Two of the key prototype tools we’ve developed are STPA-PSO and FRAM-PSO. Our prototype tools combine two parts:

- Emergent systemic qualitative risks assessment approaches (STPA, FRAM): in other words, how workers, machines, tools, software, instructions and the environment all interact.

- AI optimization (PSO): specifically, to quantify and prioritize risks, and to help decision-makers focus on what matters most.

While these terms might sound technical, the idea behind them is simple:

First, we use systemic approaches (STPA and FRAM) to map out the entire work process. This isn't just a simple flowchart; it’s a dynamic map that shows how workers’ actions, the technology they use, the instructions they receive, and the factory environment influence each other. It helps us see hidden connections and understand how one issue can trigger a chain reaction.

Then, we bring in AI. An algorithm called Particle Swarm Optimization (PSO) analyzes this complex map. It breaks down the data to quantify and prioritizes the biggest risks, so we can focus our attention where it really matters.

These hybrid and quantitive prototype tools allow us to move towards real, preventative solutions. Our prototype tools aren't black boxes; we designed them to support decision-makers, engineers and managers, with visual, understandable and actually useful results during the design phase, when it’s easier and more efficient to shape outcomes. We tested this approach across three distinct realistic industrial settings: an assembly shop, a complex disassembly line and an assembly line.

But identifying risks was only the first step. It led us to a deeper question: What kind of workplace are we trying to build?

Beyond Occupational Health and Safety: Designing for Sustainability

For us, a truly advanced workplace is a sustainable workplace, and that means looking after people and the planet, as well as profits! Our prototype tools are designed to embed sustainability into every decision. When a risk is identified, we don't just ask, "How do we fix this?" We ask, "How do we fix this in a way that’s good for our workers, our business and our environment?"

- Social sustainability: It's all about the worker. Are the smart glasses causing eye strain? Is the workflow creating stress? Our prototype tools help pinpoint and reduce these OHS risks, leading to a healthier and more productive workforce. It’s about supporting and empowering people with technology, not overwhelming them.

- Environmental sustainability: It's all about our planet. The solutions weren’t just about OHS risks, but also about designing environmentally sound processes, promoting recycling and minimizing waste.

- Economic sustainability: By preventing errors, reducing material waste, and streamlining task flows, our prototype tools improve both OHS and productivity. The result? Smarter planning, lower costs and a more resilient operation.

Ultimately, our work is about fostering true collaboration between people and technology. Industry 5.0 is not about replacing humans, but about putting them back at the center, supported and empowered by intelligent tools. With approaches and new prototype tools like STPA-PSO and FRAM-PSO, we can design systems that are not only efficient but also safe, resilient and sustainable, right from the start.

This is our fundamental belief: Health, safety and sustainability aren't costs to be managed; they are outcomes to be designed. And with the right tools, we can build a future that’s not only smarter, but more human-centric.

Additional Information

To learn more about this research, please read the following research papers:

Karevan, Ali and Nadeau, Sylvie. 2024. “FRAM effectiveness in the era of Industry 4.0: A dual perspective review”. In Proceedings of the IISE Annual Conference and Expo (Montreal, QC, Canada, May 18-21, 2024) Institute of Industrial and Systems Engineers, IISE

Karevan, A. and Nadeau, S.. 2024. “Fostering AI-human collaboration in industry 5.0 manufacturing”. In 22nd Triennal Congress of the International Ergonomics Association (IEA) (Jeju Island, Korea, Aug. 25-29, 2024) International Ergonomics Association (IEA)

Karevan, Ali and Nadeau, Sylvie. 2024. “ A comprehensive STPA-PSO Framework for quantifying smart glasses risks in manufacturing”. Heliyon, vol. 10, nº 9.