Digital technologies are rapidly transforming modern supply chains, influencing how products are produced, transported, and delivered. Among these innovations, the Digital Twin (DT) has emerged as a powerful tool for improving visibility and decision-making. A DT is a virtual model that updates in real time as physical conditions change. Once considered advanced or experimental, DTs have become increasingly accessible thanks to improvements in sensors, connectivity, and data analytics. This article explains what DTs are, why they matter, and how they can support more resilient and efficient supply chains.

What Is a Digital Twin?

A DT can be thought of as a living digital replica of a physical asset or process. It continuously receives data from machines, vehicles, warehouse systems, and sensors. As the physical environment changes, the DT updates automatically, allowing users to visualize performance, test scenarios, and identify improvements without disrupting daily operations. An everyday example can clarify this. A navigation app updates your route based on traffic. A DT works the same way, but instead of helping one driver, it helps entire supply chains. It can show how a delay at a port, a machine failure at a factory, or a sudden shift in demand will affect downstream operations.

Brief History of Digital Twins

Although the term “Digital Twin” is relatively new, the concept dates back more than 50 years. In 1970, NASA used a virtual replica of the Apollo 13 spacecraft to diagnose problems from the ground during the mission. In 2003, the idea expanded to product lifecycle management to help engineers simulate and optimize complex products.

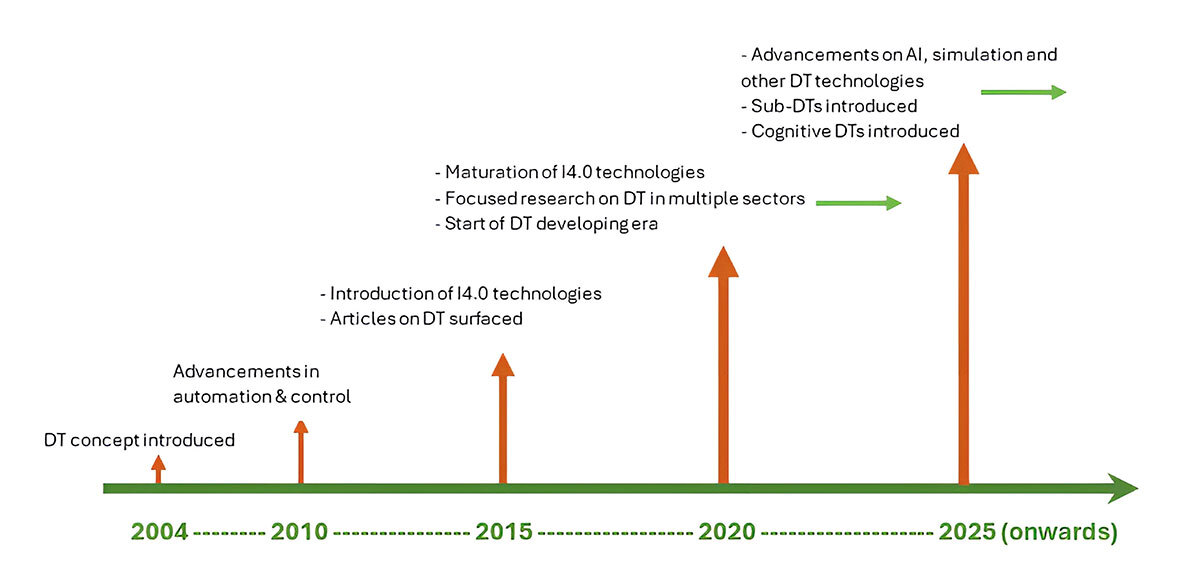

Figure 1 shows the DT progression timeline from 2004 to 2025 and beyond. It begins with early advances in automation and control, followed by the introduction of Industry 4.0 (I4.0) technologies around 2010, when DT-related articles first appeared. By 2015, I4.0 technologies had begun to mature, and DT research expanded across multiple sectors, marking the beginning of active DT development. Around 2020, DT adoption accelerated, and its applications grew across industries. The field is progressing toward advanced forms of DTs, including sub-DTs and cognitive DTs, driven by innovations in AI, simulation, and related digital technologies.

After 2014, advances in the Internet of Things (IoT), cloud computing, data analytics, and other I4.0 technologies accelerated the development of the DT. Today, DTs are increasingly used in manufacturing, energy, construction, transportation, and logistics, making them one of the most influential technologies shaping I4.0.

Why Digital Twins Matter for Supply Chains?

Modern supply chains are more interconnected and vulnerable than ever. They face challenges such as material shortages, transportation delays, environmental regulations, pandemics, and rapid changes in customer demand. Traditional planning tools often rely on historical data, which cannot always predict what will happen in real time.

DTs offer a solution by providing visibility and predictive capabilities. Organizations can use a DT to simulate “what-if” scenarios, identify bottlenecks, or test potential disruptions through the supply chain. For example, if a shipment is delayed, the DT can evaluate alternative routes and recommend the option that minimizes cost and service impact. If a production line slows down, it can estimate the impact on inventory levels and customer orders.

DTs also improve collaboration. When suppliers, manufacturers, and transportation partners share access to the same digital model, they gain a common understanding of system performance, reducing uncertainty and improving coordination.

How Digital Twins Work

Several technologies work together to support DT functionality:

- IoT sensors collect real-time data (location, temperature, equipment status).

- Cloud computing stores and processes large volumes of information.

- Cyber-physical systems connect physical machines with their digital replicas.

- Data analytics and artificial intelligence identify trends and predict outcomes.

- Simulation tools recreate realistic supply chain behavior in a virtual environment.

These components create a continuous feedback loop between the physical and digital worlds. The more complete and accurate the data, the more powerful the DT becomes.

A Simple Framework for Understanding Digital Twins in Supply Chains

A practical way to visualize DT operation in supply chains is through a three-layer framework:

- Physical Layer: Includes suppliers, production lines, logistics networks, and distribution centers.

- Digital Layer: Contains the virtual representation of these physical systems. It updates continuously as new data arrives.

- Data-Driven Modeling Layer: Uses analytics and simulations to test alternatives, predict outcomes, and support decision-making.

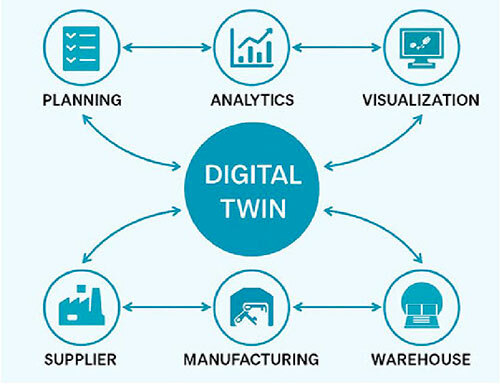

Organizations can adopt this framework gradually. They often start with a single process, such as a warehouse or manufacturing cell, and expand their DT step by step until it reflects the entire supply chain. Figure 2 illustrates how a DT acts as a central hub that connects and enhances different parts of a supply chain or industrial system. By creating a virtual representation of real-world operations, a DT supports planning, analytics, and visualization while linking key areas such as suppliers, manufacturing, and warehousing. This interconnected model allows organizations to monitor performance, predict outcomes, and make better decisions across the entire process.

Challenges and Opportunities

Implementing a DT comes with challenges. High-quality, real-time data is essential, but many organizations still rely on manual records or outdated systems. Cybersecurity is another concern, especially when data travels across multiple partners. Interoperability between different systems and employee training also require careful attention. Nevertheless, these barriers are decreasing as the technology becomes more accessible. Many companies now view the DT as an essential tool for improving efficiency, reducing risk, and enhancing sustainability.

Future of Digital Twins in Supply Chains

DTs represent an important step toward more adaptive, resilient, and environmentally responsible supply chains. They enable organizations to anticipate problems, reduce waste, and respond quickly to disruptions. As IoT devices, analytics platforms, and automation continue to advance, DTs are expected to become a core component of future supply chain strategy.

Additional Information

For more information on this research, please read the following paper: Syed Adeel Haneef Zaidi, Sharfuddin Ahmed Khan, Amin Chaabane, Unlocking the potential of digital twins in supply chains: A systematic review, Supply Chain Analytics, Volume 7, 2024, 100075, ISSN 2949-8635.