The Duality of Ultraviolet Light

Ultraviolet (UV) light occupies the 100 to 400 nm spectral range, which is subdivided into UVC (100 to 280 nm), UVB (280 to 315 nm), and UVA (315 to 400 nm). While the sun is its primary natural source, UV is also produced by artificial sources like germicidal and tanning lamps. This radiation presents a significant duality: it is essential to health, aiding in vitamin D production and blood pressure regulation, and for applications ranging from sterilization to phototherapy. However, overexposure carries severe risks, including sunburn, premature skin aging, vision damage, and material photodegradation. Critically, UV radiation is a known carcinogen across its entire range. To safely harness its benefits while mitigating these dangers, it is important to quantify cumulative UV doses in real time during outdoor or workplace activities.

Despite progress in UV sensing, current technologies have notable limitations, including low material flexibility, complex fabrication, and reliance on costly scientific instruments or subjective visual inspection. For example, polysulfone films, considered the gold standard in UV dosimetry, undergo an irreversible color change upon exposure. However, interpreting this change to determine a cumulative dose requires a spectrophotometer and calibration curves, tools that are impractical for the general public. To bridge this gap, we have fabricated a highly flexible optical fiber. This technology aims to provide a more reliable, accessible, and accurate sensor that offers a convenient alternative to rigid UV light detectors, making it ideal for integration into wearable devices and textiles.

Designing a New UV Sensor

We chose to design our sensor as a flexible optical fiber, much like a strand of fishing line, for several key reasons. This design is easy to integrate into wearable devices and textiles, and works well with the simple electronic parts needed to build a quantitative optical sensor, like LEDs and photodetectors. Research also shows that the fiber's operating principle makes it far more sensitive than a simple flat film. Indeed, the long interaction length between the sensing material and the light guided along the fiber amplifies the sensing effect. Additionally, optical fibers are immune to electromagnetic interference and corrosion, and therefore resistant to outside conditions.

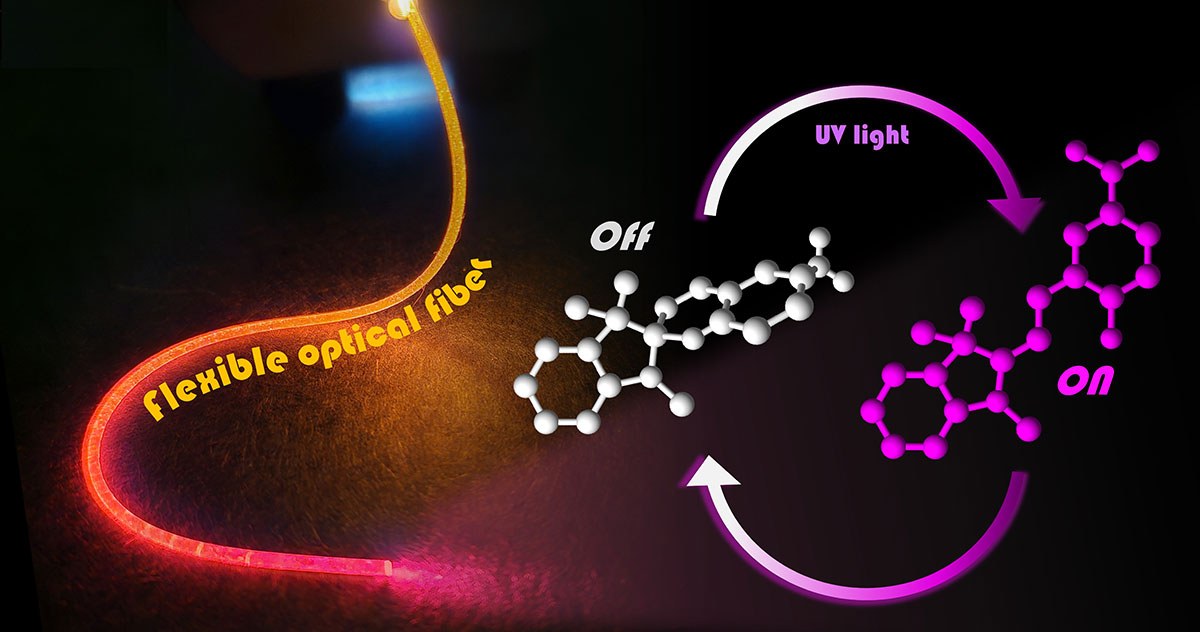

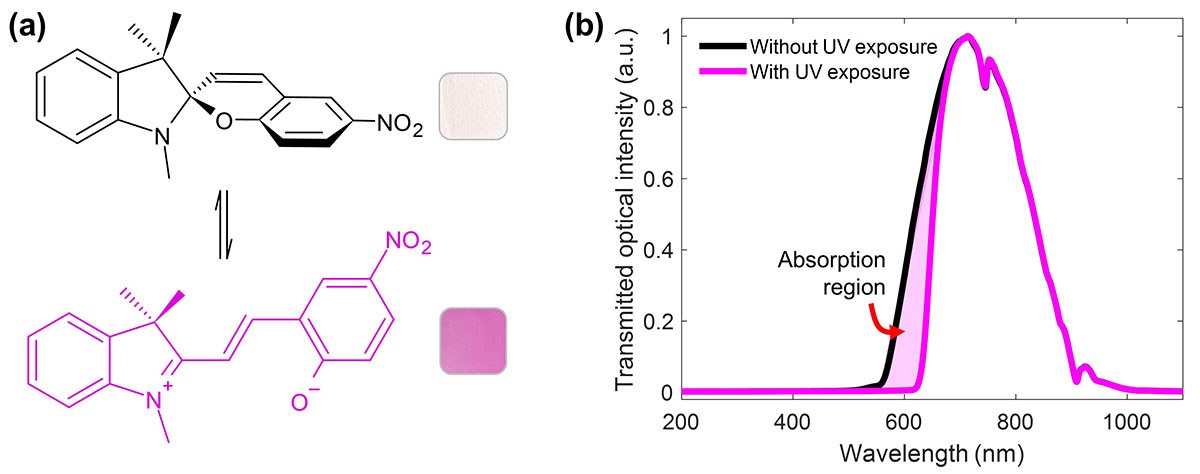

To build this fiber, we needed a material that was transparent so light could travel through it, but also supple and highly flexible—think of the elastic in clothing—so it could be worn comfortably and withstand constant movement. It also had to be resistant to UV damage. Ideally, it would also be biocompatible to minimize adverse reactions when in direct contact with the skin. The perfect candidate was poly(dimethylsiloxane) (PDMS), the same silicone used in medical implants, whose interesting properties are detailed in our review paper (see reference below). However, a clear silicone fiber alone cannot detect UV light. To give it this sensing ability, we embedded a special organic dye called Spiropyran. This dye acts like a light-activated molecular switch. In its "off" state, the dye is colorless. But when exposed to UV light, the molecule changes shape and switches to its "on" state (Figure 1a). This new pink form acts like a color filter, absorbing a specific portion of the light traveling through the fiber (Figure 1b). The more UV light the fiber is exposed to, the more "switches" are flipped, and the more the signal is reduced. Once the UV light is gone, the molecular switch flips back, the pink color fades, and the sensor is ready to be used again.

Putting the Optical Fiber to the Test

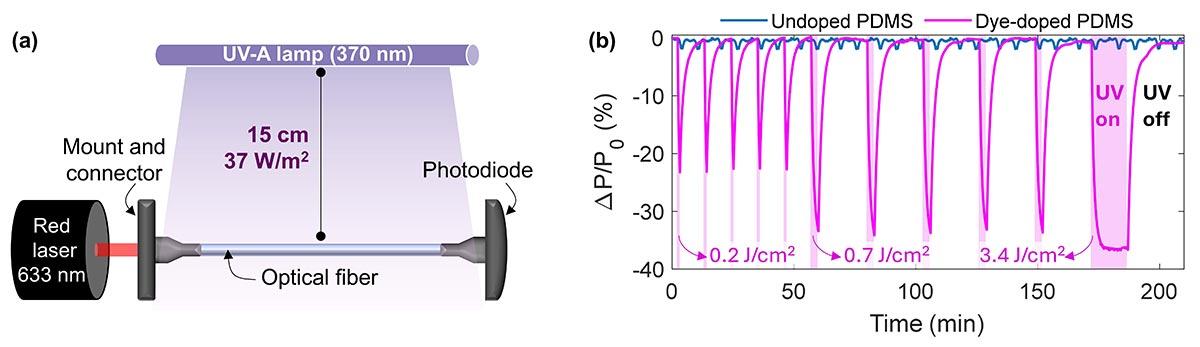

To test the fiber's response to UV light, we sent a 633 nm red laser beam through it and measured the output using a light sensor (photodiode), as shown in Figure 2a. This wavelength of red light aligns with the fiber's peak absorption, making changes easily detectable. The fiber was then exposed to a UVA lamp (370 nm) at several doses (0.2, 0.7 and 3.4 J/cm²) to measure its response (Figure 2b).

As seen in Figure 2b, the amount of light passing through the dye-doped PDMS optical fiber [∆P/P0 (%)] sharply dropped the moment the UV light was turned on. This is the light-sensitive dye at work: UV light triggers a structural change, blocking the red laser. When the UV light was turned off, the recovery process began, until the optical fiber became transparent again, showing a reversible effect over many cycles at different UV doses. The sensor’s sensitivity was estimated at 115 % per unit of UVA dose, reaching its maximum response at a UV dose of 0.4 J/cm².This detection range is aligned with real-world applications like agricultural lighting, 3D printingand phototherapy. Remarkably, the fiber’s performance is unaffected by bending, making it perfect for use in textile or wearable sensors.

Conclusion

In this work, we have demonstrated that a silicone (PDMS) mixed with a smart dye (molecular switch) can be used as a highly flexible and robust optical fiber sensor for UV dose monitoring. Its rubber-like nature makes it an excellent candidate for integration into smart textiles and wearable devices, enabling convenient and personal continuous UV monitoring, while offering a practical alternative to traditional rigid UV detectors.

A friendly reminder: don’t forget the sunscreen! 😊

Additional Information

To learn more about this research, please read the following research papers:

Zimmermann, C. A., Amouzou, K. N., Sengupta, D., Kumar, A., Demarquette, N. R., & Ung, B. (2024). Novel elastomeric spiropyran-doped poly(dimethylsiloxane) optical waveguide for UV sensing. Frontiers of Optoelectronics, 17(1), 21. https://doi.org/10.1007/s12200-024-00124-4

Zimmermann, C. A., Amouzou, K. N., & Ung, B. (2025). Recent Advances in PDMS Optical Waveguides: Properties, Fabrication, and Applications. Advanced Optical Materials, 13(1), 2401975. https://doi.org/10.1002/adom.202401975