LTCC@ÉTS

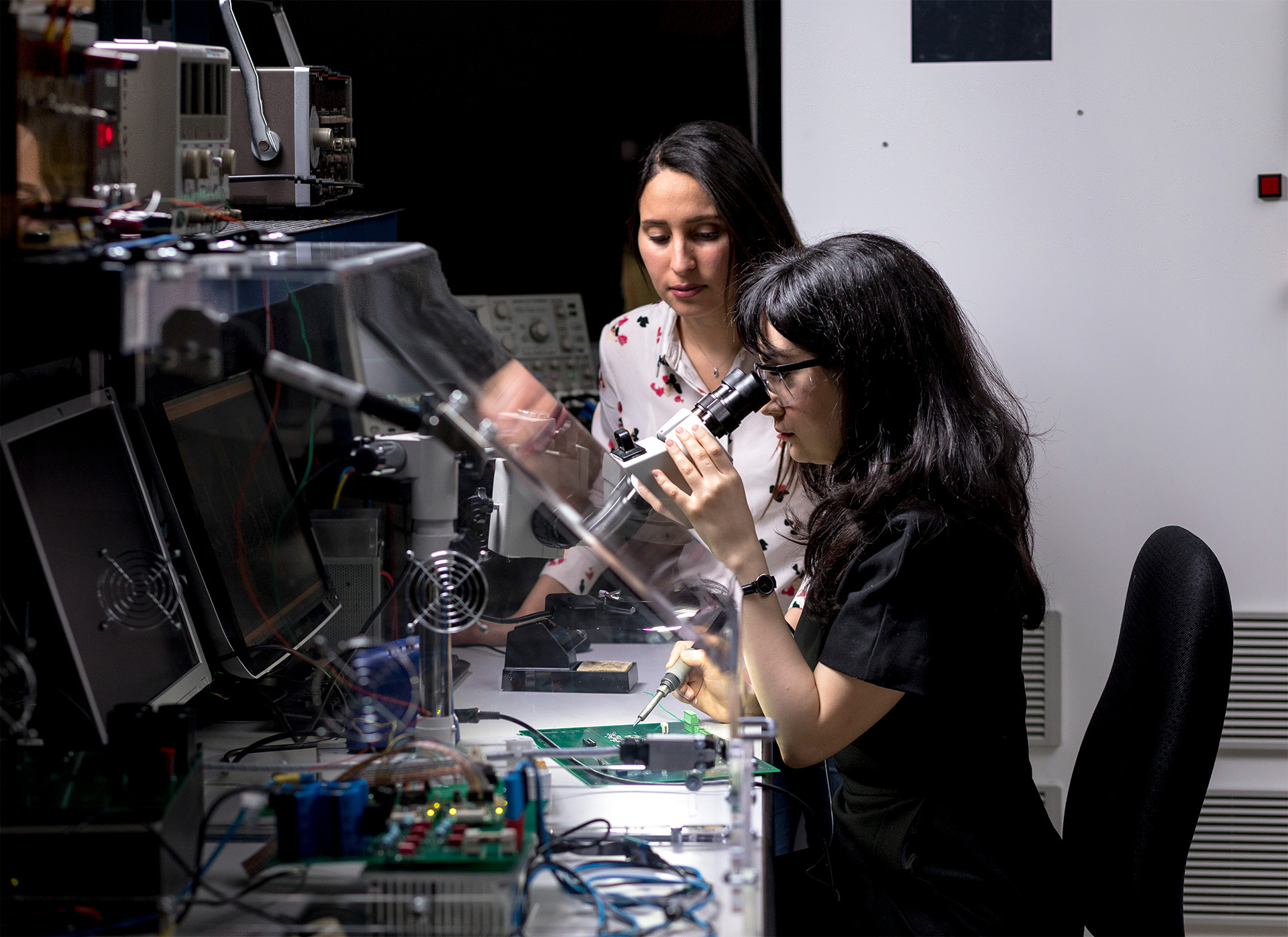

Presentation of the LTCC@ÉTS laboratory

LTCC is the abbreviation of "Low Temperature Co-fired Ceramic". This technology is a way to produce low cost ceramic multilayer circuits using single soft tapes, which are used to apply conductive, dielectric, or resistive pastes on. It is well suited to realize innovative RF and microwave components and sub-systems.

Compared to a conventional multi-layer laminate structure, such as FR4, LTCC offers a number of advantages:

- Lower loss dielectric.

- Better controlled dielectric properties.

- Well suited to producing modules in low-cost SMT packages (BGA, QFP, PLCC, etc..) as well as bare dies.

- Cavities and integral heat sinks can be easily realized.

- Capability to include embedded passive components such as resistors, capacitors and inductors.

Expertise and services

The LTCC@ETS laboratory can help you for:

The first of its kind in Canada, the LTCC (Low Temperature Cofired Ceramic) process at ÉTS offers prototyping and low volume production capabilities of multilayer ceramic circuits. Thanks to the ceramic materials used and to the inherent 3-dimensional circuit integration capabilities of the LTCC process, this technology offers several advantages such as:

- Excellent performance at microwave and millimeter wave frequencies.

- Considerable circuit miniaturization and high circuit integration density.

- Integration of housing in the circuit fabrication process (System in Package).

- High thermal stability for reliable circuit operation under harsh environmental conditions.

- Excellent hermiticity with no water absorption for reliable operation in wet/humid environments.

Here is a list of documents that you can download:

- Our brochure (PDF) with a summary of our design rules

- Ferro L8 LTCC green tape datasheet (PDF)

- Ferro A6M LTCC green tape datasheet (PDF)

- Dupont 951 LTCC green tape datasheet (PDF)

- Dupont 9K7 LTCC green tape datasheet (PDF)

- You can also download our ADS library definitions (ZIP - for academic use only).

We are committed to providing a website that is accessible to all users. If you have difficulty accessing this content due to accessibility issues, please contact the laboratory.

We can help you develop your idea from concept development to design & modeling and prototype fabrication using our hi-tech tools.

During the concept development phase, we can help you with the following:

- Initial design (including mask design) and preliminary process sequence design for implementing your device for its intended application.

- Analysis of device designs, fabrication approaches, as well as for each step in a process sequence.

- Determination of a realistic timeframe and budgets.

In your MEMS device design & modeling efforts, we can help you with the following:

- Development of a set of models, preliminary process sequence(s), and prototype mask layout set.

- Create and refine analytical and/or numerical device design models (e.g., finite-element and/or boundary-element models) to allow the accurate prediction of the physical behavior of your MEMS device.

- Create designs of test structures to accurately measure the properties of the materials used in a fabrication process.

In your MEMS device prototyping efforts, we can help you with the following:

- Selection of the best processing steps for fabrication of your device.

- Development of custom processes, including process steps, process modules, and complete process sequences.

- Implementation of yield and quality improvement methodologies.

Facilities

LTCC Fabrication

Equipment

- LTCC printer: P200S

Manufacturer: KEKO - LTCC perforator: PAM4s

Manufacturer: KEKO - Cutting and ablation: Protolaser U3

Manufacturer: LPKF - Cutting machine: CM-15A

Manufacturer: KEKO - Automatic stacker: IS4PL

Manufacturer: KEKO - Isostatic press: ILS66S

Manufacturer: KEKO - Cofiring oven: PEO603

Manufacturer: ATV

We are committed to providing a website that is accessible to all users. If you have difficulty accessing this content due to accessibility issues, please contact the laboratory.

MEMS Fabrication

We are committed to providing a website that is accessible to all users. If you have difficulty accessing this content due to accessibility issues, please contact the laboratory.

Equipment

- Plasma deposition: SPT-330H

Manufacturer: Plasmionique - Mask aligner: 800MBA

Manufacturer: OAI - Wet bench with DI water generator

Manufacturer: STC - Resin deposition: WS-400BZ-6NPP/LITE

Manufacturer: Laurell - Direct exposition system: SF100

Manufacturer: Intelligent Micro patterning - IBE-RIE: Nanoquest I

Manufacturer: Intelvac - CMP: RBPo-6

Manufacturer: Rtec Instruments

Team

Students

- Madiha Achouri (master)

- Ines Amor (doctorate)

- Charazad Bensid (master)

- Mustafa Elarbi (master)

- Ehsan Fallahnia (doctorate)

- Sabrine Idoudi (doctorate)

- Mehdi Khoee-Kholenjani (doctorate)

- Zina Mohamed (doctorate)

Research projects

Dorra Bahloul's project

Dorra Bahloul is a PhD student in the Electrical Engineering Department at École de technologie supérieure (ÉTS) in Montreal, where she began her master studies. Her research interests focus on the development of reconfigurable RF and microwave components and systems, with specific emphasis on MEMS and LTCC technologies. She works on the development of MEMS process directly on LTCC substrate.

This process will be then used for the development of novel types of adaptive and miniaturized RF components with enhanced RF performances. An agile amplifier where the different key blocks like matching networks as well as control circuits and thermal management structures are formed on the same LTCC multilayer substrate is a potential application of this work.

Mustafa Elarbi's project

With the increasing widespread use and popularity of cell phones, laptops and similar electronic mobile equipment, there is a subsequent rising need for faster operational speeds. At the same time, increasing amounts of energy are both being used and demanded. How to satisfy these growing needs through longer battery life is currently a major focus of research.

Power amplifiers (PAs) on wireless devices are causing endless problems for users of wireless telecommunication equipment due to their drain on the power system.

Researchers are also looking into ways to increase the operational power-added efficiency (PAE) in amplifiers. With PAE increased, the device is able to output the same amount of power with less DC power consumed.

Non-linear Class-F and Class-F-1 PAs have drawn the most attention among all different classes of PAs from engineers because of their capability of outputting high power and providing good PAE. Class-F boosts up PAE by controlling the harmonic content at the output. Advanced Design System (ADS) from Agilent is used for design and simulation class F power amplifier based on the ADS model of Cree’s CGHV1J006D high electron mobility transistor (HEMT). A high efficiency power amplifier is fabricated on LTCC. In this design, the harmonics at the input are controlled as well as the harmonics at the output. An input wave-shaping network is designed to shape the waveforms at the gate. By terminating harmonics with proper impedances at the output, a square voltage waveform and a half-sine current waveform are obtained at the transistor drain terminal. The overlapping area between the voltage and current waveforms can be reduced as well as the active device power consumption.

The final design operating at 5 GHz produced a PAE of 72% with 38.50dBm output power in simulation and I am still measuring the results of fabrication.

Hana Mohamed's project

The research focus on the embedded system for RF vector measurements in frequency agile and reconfigurable Front-Ends to be tuned and operate at the frequency of choice. This technique realise on measuring the amplitude and phase of two RF signals through two power detector circuits using four-port reflectometer which simulated by HFSS and fabricated by using LTCC martial. The proposed reflectometer consists of TL transmission line which connected to port 1 (source) and port 2 (load), two vais (implement the sniffers) that placed close to TL and separated by the distance d, and two power detecting circuits (LTC558) which are placed at port 3 and 4 respectively. This reflectometer characterized by very small size and very low coupling (below -30 dB) so that become suitable for circuit integration and embedded measurement. This topology can be integrated in different application such as Six-port Technique and Monolithically Gain Phase Detection which require using directional coupler to sample the two waves for which the complex ratio is to be measured.

Madiha Achouri's project

Nowadays, location-based services are integral part of everyday life. In addition, there are more and more GNSS constellations being deployed. This will help improve the accuracy and precision of positioning from some meters to some centimeters, in real-time and at any point on the Earth or on space. This involves sophisticated GNSS receivers which in turn require GNSS simulators able to generate a large number of GNSS signals from a variety systems, such as GPS, Glonass, Galileo, Compass (Beidou-2), QZSS etc., and their multipath components. In this context, simulators that use dedicated hardware, such as FPGAs, become too costly and may even not be feasible. This project will target ways to leverage the full power of commercial CPUs and GPUs to address this challenge. In order to accomplish this, issues related to computer hardware resource management, operating systems interrupts and constraints as well as software/hardware co-design will be investigated.

Partners

The LTCC@ETS lab members are actively involved in different projects in close collaboration with various insdustrial and university partners:

- Vibrantz (formerly Ferro): supports us in LTCC innovation by providing their A6M and L8 tape system.

- C12 Advanced Technologies: supports us in LTCC innovation by providing carbon tapes and LTCC separator powder sheets.

Ammar B. Kouki, Director of LTCC@ÉTS

514 396-8554

ammar.kouki@etsmtl.ca

Normand Gravel, Laboratory manager and technician LTCC-MEMS

514 396-8800 ext.7309

normand.gravel@etsmtl.ca

Research at ÉTS

ÉTS provides an ideal environment for conceiving and creating the ideas that will shape the world of the future.