Replacing Synthetic Oils in Capacitors

Purchased on Istock.com. Copyright.

For decades, the technology to manufacture capacitors used in high-voltage systems required the use of synthetic oils as a dielectric wall. These oils have a harmful effect on the environment and on the health of operators in close contact. This paper presents the preliminary results of a study that proposes the development of oil-free capacitors with a similar or better performance than that of those impregnated with oil. Keywords: high-voltage capacitors, resin, impregnation, film.

Dielectric Walls in Capacitors, a Technology that Needs Upgrading

The development of different insulating materials used as dielectric walls in capacitors has revolutionized capacitor manufacturing technologies. These materials play a key role in load control and energy storage. Before the 1970s, kraft paper coated in mineral oil (polychlorinated diphenol) was the main dielectric used in capacitors. Afterwards, because of their low dissipation factor, high dielectric strength, good stability and high accessibility, polymer films gradually replaced kraft paper in capacitors. The switch from paper to polymer film has also shortened the capacitor manufacturing process by reducing the drying time needed for paper before impregnation with oil (Hantouche, 1996; Qi, Petersson, & Liu, 2014).

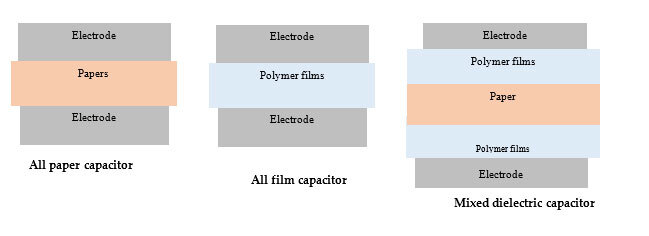

Fig. 1. Different capacitor configurations (not to scale)

The current manufacturing technology for high-voltage capacitors involves using a stack of thin strips (electrodes and dielectric wall) wound in configurations that may change (see Fig. 1) depending on the expected electrical performance. The wound coils are assembled in series or in parallel, forming the so-called active part of the capacitor. Usually, to protect the active part from air and moisture and to fill possible voids, it is inserted in a waterproof insulator and impregnated with a synthetic oil.

Fig 2: Oil capacitors

Although synthetic oil capacitors currently have a high electrical reliability, there is a need to upgrade technology to replace synthetic oils because of their harmful effect on the environment and the safety risk they pose in the workplace. In addition, new environmental protection and conservation regulations may prohibit the use of synthetic oils within a few years. Therefore, there is an urgent need to meet the new challenges in dielectric materials and to enable capacitors to meet health and environmental requirements (Samuel, Lucas, Fu, Howard, & Lafon-Placette, 2012).

The characterization project of new dielectric walls based on thermosetting resins, under the supervision of Professors Éric David and Simon Joncas—a research team from the Department of Mechanical Engineering and the Department of Systems Engineering at ÉTS—is presently looking for solutions to replace dielectric oil with thermosetting resins. The properties of the new dielectric system (films & resin) are characterized mainly by using partial discharge (PD) measurements. This technique ensures that the manufactured capacitors are free of cavities or delamination. Indeed, PD occurrences during the capacitor operation damage its dielectric wall. PD measurement is therefore used as a process quality control method, since a sample with PD cannot be accepted.

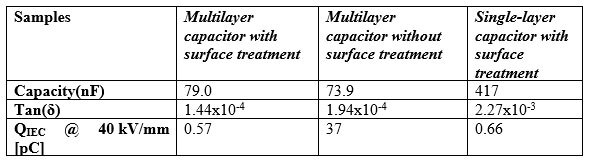

Table 1: PD, capacitance and dissipation factor measurements at 60 Hz

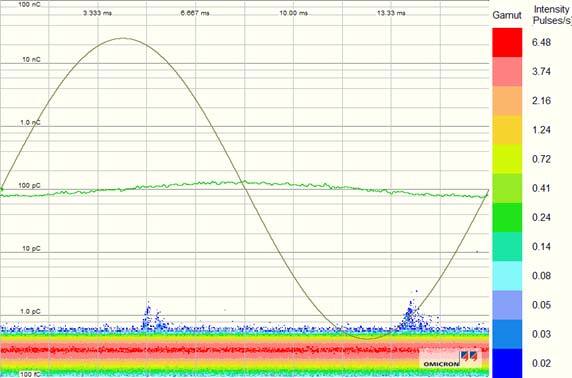

a)

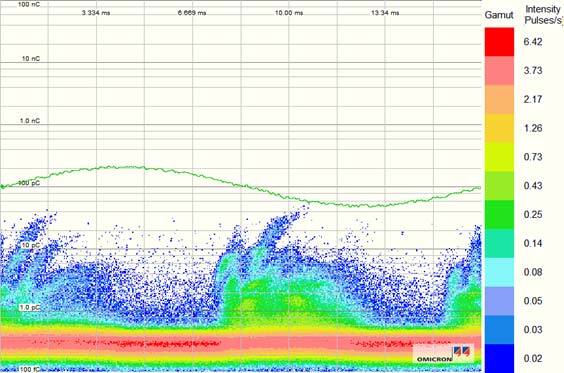

b)

c)

Fig. 3. PD histogram under an electrical stress of 40 kV/mm for different samples of oil-free manufactured capacitor; a) Single-layer capacitor with surface treatment, b) Multi-layer capacitor without surface treatment, c) Multi-layer capacitor with surface treatment.

Figure 3 shows the PD histograms for different dielectric wall configurations. Comparing PDs with these results shows that “rabbit ear” type PD patterns were observed in the multi-layer capacitor without surface treatment (Figure 3b). The single-layer capacitor with untreated surface shows a low PD level. The surface-treated multi-layer capacitor does not exhibit PD under an applied electrical stress of 40 kV/mm. These results confirm the quality of the impregnation method, the choice of material and surface treatments as well as the potential use of this new technology.

Conclusion

These preliminary results show a significant increase in performance of the dielectric wall with the surface treatment of films impregnated with a commercial thermosetting resin. Also, in its further development, a single-layer dielectric wall does not appear to be suitable for oil-free applications.

Additional Information

This paper was presented at the IEEE 2020 International Conference on Dielectrics (ICD 2020) (available shortly).