Optimizing the Reverse Logistics of Medical Face Masks

Purchased on Gettyimages. Copyrights.

The Importance of Face Masks

In recent years, face masks have become an essential public health tool to prevent the spread of airborne infections and germs. As an example, the Canadian government implemented mandatory face mask wearing in public spaces in all provinces from 2020 to 2022 to slow the spread of the COVID-19 pandemic (Karaivanov et al., 2021).

Consequences of the Increased Use of Face Masks

This unfortunate event generated an unprecedented increase in face mask use and an alarming production of plastic waste on a massive scale. According to the World Health Organization (WHO), people worldwide wore approximately 129 billion face masks monthly in 2021 (Oginni, 2022). Assuming that each face mask weighs 3.5 grams, this equates to 451,500 tons of waste per month generated around the world that year alone (Occasi et al., 2022). In addition, many sectors were using this protective equipment even before the pandemic, such as the health, food, veterinary, electronic, chemical, and mining sectors. This confirms the urgency to implement adequate processing or disposal of this product at the end of its useful life.

Proposed Alternatives

This sparked an interest in used masks processing alternatives. After completing a decontamination process, used face masks could be recycled to produce polypropylene pellets (Saraswaty et al., 2021), a valuable material that is largely used in industry to manufacture plastic products. In addition, the metal contained in face masks (the part that covers the nose) could be extracted and sold to other industries.

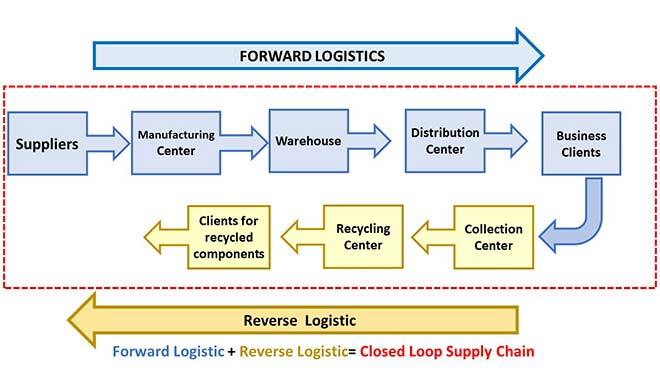

Therefore, there is a need to develop strategies to efficiently collect and recycle masks at the end of their useful life. From the logistics perspective, establishing reverse logistics networks (RLN) or closed-loop supply chains (CLSC) is an interesting avenue. A configuration of such supply chains is depicted in Figure 1. Designing and optimizing RLNs or CLSCs helps us determine the most efficient paths for end-of-life product collection and recovery, such as recycling, to favor value creation from what would otherwise be considered a contaminated pollutant. This is an example of how a component of the circular economy could be implemented in practice.

Figure 1: Schematic representation of a closed loop supply chain

Proposed Mathematical Model

The main goal of this research project is to propose a decision support tool to determine the best RLN or CLSC design in dealing with end-of-life procedural face masks considering different parameters, constraints, and scenarios.

To achieve this goal, we developed a mixed integer linear programming (MILP) model that includes the revenues from selling face masks, polypropylene, and aluminum, as well as the costs of raw materials, transportation, manufacturing, and recycling. Several constraints were also considered, including suppliers, production and transportation capacities, demand satisfaction, and preserving material flows in the network.

Decisions to be made include determining material flows in the network and supplier selection of raw materials. The objective is to maximize profit. Furthermore, the Return on Investment—ROI (Profit/Investment)—was calculated to evaluate the economic viability of the proposed CLSC or RLN, and various scenarios were analyzed to identify profitability conditions. For example, we considered varying the percentage of collected masks (e.g., 80%, 50%, or 25%) and proposed different locations for collection and recycling centers.

Results show that expanding and sharing existing facilities (warehouse or manufacturing centers) for collecting and recycling used masks are some of the conditions that will lead to profitability. It is not recommended to establish an RLN to collect and recycle masks unless it is integrated with the supply chain (CLSC) or a substantial government subsidy is granted.