Mechanical Evaluation of Geosynthetics in Bituminous Pavements

Purchased on Istock.com. Copyright.

Mechanical evaluation in a laboratory environment of deteriorated bituminous layers reinforced with a layer of geosynthetics is a challenging task in terms of attaining rational values as inputs in performance-based design methods. The complexity has two origins. On the one hand, the current practice of specimen preparation and test methods needs to be updated to consider the mechanical effect of the interlayer; on the other hand, results derived from the developed test methods must be a genuine reflection of the field response under real conditions. The focus of this paper is to present new findings through novel approaches on the mechanical reaction of a reinforced-rehabilitated asphalt overlay to traffic and temperature fluctuations. Keywords: Reinforced-Rehabilitated Asphalt Concrete; Geosynthetic Material; Mechanical Response

Evaluating Geosynthetics Efficiency: A Challenge

Geosynthetics are synthetic polymeric materials progressively employed in practice as an interlayer within different levels of pavement cross sections to enhance the mechanical performance of the system, thanks to its high tensile strength and elongation under loading [1]. In this respect, applying geosynthetics followed by a new asphalt overlay over a deteriorated bituminous surface has recently received much interest as a way to delay the propagation of reflective cracking from the tip of an existing discontinuity to the top surface that is subject to passing traffic wheels [2–6]. On top of that, this newly developed technique could take the economic burden of maintenance activities required to restore road serviceability to users away from pavement authorities. However, gaining an in-depth knowledge of the mechanical response of a reinforced system using geosynthetics is essential to ensure a widespread usage of these reinforcing materials.

Furthermore, the majority of test methods and their relevant available equipment in context to evaluate the mechanical responses of an asphalt overlay were designed to include solely one type of material. In the presence of different types of materials, like in a reinforced structure, considering the interaction between the layers while assessing the mechanical response of the whole system is of paramount importance.

Cracks in a paved road

Besides, a variety of geosynthetic materials are available in the market. In terms of pavement application, geogrid, geotextile—sometimes called paving fabric—and geomembrane—a combination of geogrid and geotextile—are those whose suitability to reinforce a pavement system are well documented in the literature [1]. Nevertheless, every one of these products play a designated role in the pavement structure, which requires different test methods to capture their possible mechanical benefits.

Finally, it should be emphasized that the current practice in the structural design of a pavement system does not take into account the mechanical effects of the paving fabric [7]. This stems from the lack of reliable test methods to properly specify the mechanical changes in a reinforced system.

Testing Setups and Results

In this section, new approaches to quantify the mechanical effects of geotextiles between two separate asphalt concrete layers are discussed. To highlight the differences, results will be compared with the traditional rehabilitation method, which only takes advantage of a new asphalt overlay attached to the existing cracked layer through the application of a thin layer of tack coat—a thin film of asphalt emulsion to provide adhesion between layers.

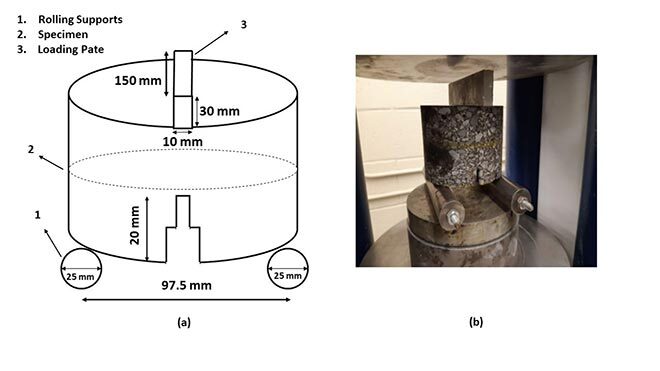

As mentioned earlier, the main purpose of introducing paving fabrics between dissimilar bituminous layers is to postpone crack propagation and discontinuities existing in the old bottom layer to the top surface of the newly applied asphalt overlay, and to waterproof the system against water percolation. To simulate the crack generation phenomena in a bilayer structure in a laboratory environment, the conventional 3-point bending test (3-PBT) was modified by taking advantage of a notched cylindrical-shaped specimen loaded with a straight plate at the top and supported by two bars at the bottom, as illustrated in Figure 1.

Figure 1. Modified 3-PBT: (a) schematic design; (b) test setup

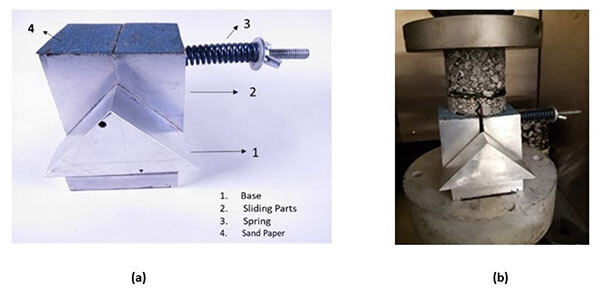

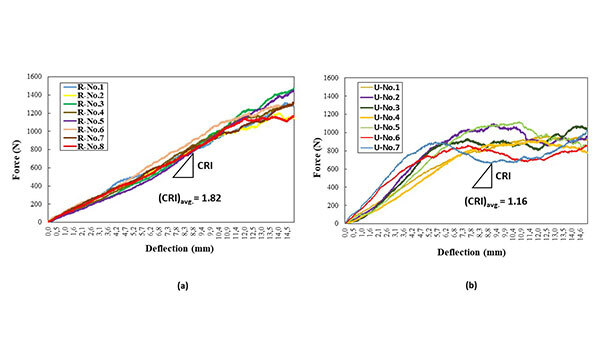

In the second stage, the crack propagation phase driven by temperature fluctuations was reproduced via a newly developed device named crack-widening device (CWD), which can evaluate the crack resistance property of the system in a variety of crack widths. Figure 2 demonstrates a schematic view of the CWD. Enhancing the anti-reflective property of the system was quantified by defining a crack resistance index (CRI), which is actually the slope of the force-displacement curve developed during the crack propagation stage. As seen in Figure 3, on average, the reinforced structure could enhance by 40 percent the anti-reflective property of the system.

Figure 2. Crack widening device (CWD): (a) schematic design; (b) test setup (adapted from [8])

Figure 3. Force-displacement curves for: (a) reinforced structure with paving fabric; (b) unreinforced structure (adapted from [8])

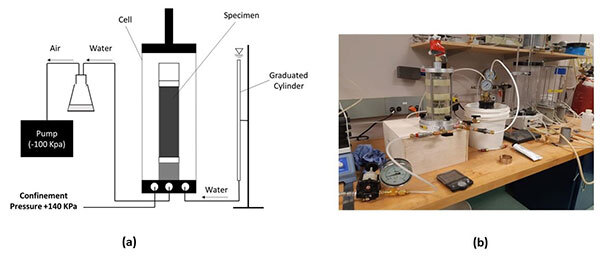

Figure 4. Water-vacuum permeability device (WVPD): (a) test design; (b) test setup

This test revealed that the reinforced structure could retain its impermeability sufficiently in different crack widths compared to the corresponding unreinforced structure.

Conclusion

This study was conducted to evaluate the mechanical benefits of using paving fabrics between bituminous layers. Results showed that the reinforced system could retain its structural integrity even at high crack widths present at its bottom layer. Besides, in reinforced systems, the crack width reflected from the bottom to the top surface was three times lower than in similar unreinforced cases, showing its suitability to delay reflective cracking. Additionally, the reinforced systems showed a great potential to withstand water movement, even under accelerated test methods, compared with unreinforced systems.

Additional Information

For more information on this research, please read the following research paper:

Solatiyan E, Bueche N, Vaillancourt M, & Carter A (2020) Permeability and mechanical property measurements of reinforced asphalt overlay with paving fabrics using novel approaches. Materials and Structures, 53(1), pp.1-15.