A Global Need for Simple and Affordable Water Solutions

Access to safe drinking water remains one of the world's greatest challenges. While urban centers in industrialized nations rely on complex and costly treatment plants, many small or remote communities, particularly in developing regions and northern areas, lack the infrastructure, technical expertise or financial means to operate such systems. Conventional processes rely on multiple tanks, precise pH and dosage control, and the use of metal-based coagulants such as alum, which require trained operators and constant supervision.

To address this global issue, an innovative, compact water treatment process that is both simple and efficient, capable of simultaneously improving water quality and sludge dewatering, has been developed at the École de technologie supérieure (ÉTS) in Montréal. Using fiber-based super-bridging agents that form very large flocs, the system can simultaneously purify water and dewater sludge in a single step. This innovative, low-maintenance solution offers a promising alternative for decentralized water management, and could help extend access to safe water to communities long excluded from conventional treatment systems.

A Compact Three-in-One Process

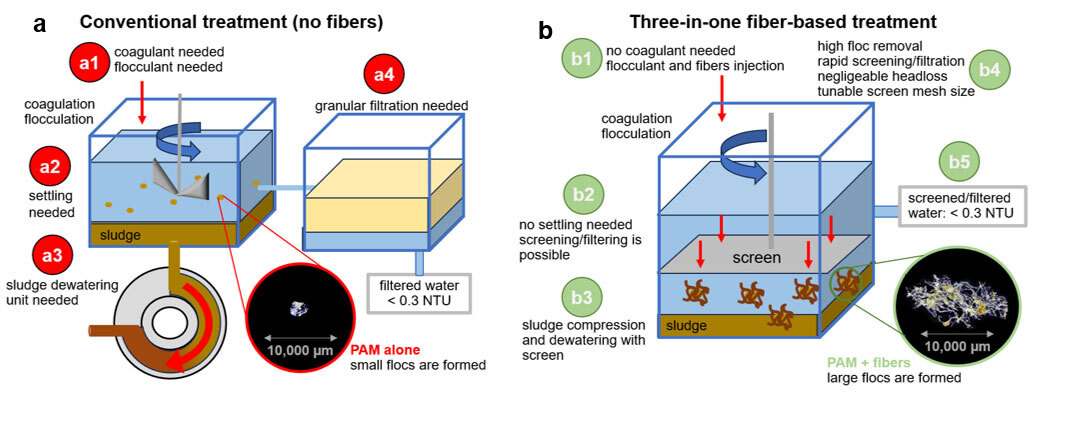

The new system integrated three treatment stages (flocculation, separation and sludge dewatering) into a single, compact unit. Its effectiveness relies on the use of fibrous super-bridging agents, which are natural cellulose fibers made from recycled paper that act like tiny natural nets in the water. These fibers capture and bind small particles together, forming very large and stable clusters called flocs. When combined with a small amount of flocculant (polyacrylamide or PAM), the fibers form extremely large and stable flocs that can be efficiently removed using a coarse screen instead of large settling tanks.

This approach eliminates the need for multiple treatment stages and simplifies operations. The same reactor that separates the flocs can also press and dewater the resulting sludge, avoiding the use of additional chemicals and reducing the overall footprint of the process.

Transforming Complex Chemistry Into Simple Mechanics

Conventional treatment plants rely on a chain of chemical and physical steps (coagulation, settling, filtration), each requiring separate tanks and careful control. This new process simplifies all this into one compact unit.

Instead of relying on complex chemistry, it uses the physical action of cellulose fibers to do most of the work. These paper-like fibers create bridges between suspended particles, helping them stick together and form large, dense flocs that are easy to trap.

Because these flocs are visible and heavy, they can be removed using simple screen filters instead of fine membranes or settling tanks. This turns a delicate chemical operation into a robust mechanical process, reducing maintenance needs and making it ideal for decentralized or off-grid water treatment.

Key Results: Cleaner Water and Drier Sludge

Tests conducted on both Canadian surface water (St. Lawrence River) and highly turbid waters from the Democratic Republic of the Congo (DRC) demonstrated the versatility and remarkable efficiency of this technology. For comparison, the St. Lawrence River—already relatively clear—shows an initial turbidity of about 4 NTU, while raw water from DRC can exceed 500 NTU, similar to muddy river water after a storm. Despite these extreme differences, the system performed remarkably well.

When fibers were added, turbidity removal—a measure of water clarity—rose from 39% to 94%, bringing the treated water below 0.3 NTU, which meets North American drinking water standards. Turbidity simply describes how cloudy the water appears: the lower the value, the clearer and safer it is. This technology also tackled emerging pollutants. In tests on the St. Lawrence River, nanoplastic removal increased from 20% to 72%, and microplastic removal reached up to 95%. In the highly turbid waters of the DRC, more than 99% of suspended particles were removed while using fewer chemical additives than conventional methods.

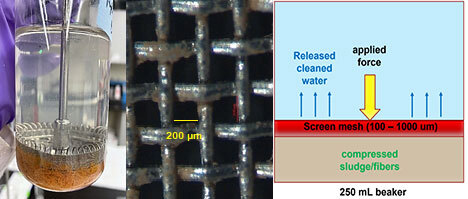

The process also proved highly effective for sludge dewatering. Once pressed, the solid content of the sludge increased more than tenfold compared to conventional treatment, reducing the amount of waste to be transported and the energy required for drying. These results confirm that fibrous materials not only improve contaminant removal, but also make sludge management more efficient and easier to operate.

Large flocs settle and are separated using a coarse screen mesh (image on the right shows a 200 µm screen). Simplified diagram of the dewatering stage, where pressure is applied to compact the fiber–sludge layer and release clean water. From Mebarki et al., npj Clean Water 2025.

A Step Toward Decentralized Treatment

The simplicity and scalability of this three-in-one fibrous process make it especially well-suited for decentralized water treatment in small towns, rural areas and marginalized communities. Unlike conventional plants, it operated without heavy infrastructure, complex control systems or continuous chemical adjustment.

Because the process uses renewable cellulose fibers and low doses of flocculant, it reduces environmental impacts and operational costs. It can also help minimize the health and environmental risks associated with poorly managed sludge. This makes it a promising solution for achieving the United Nations Sustainable Development Goal 6, which aims to ensure universal access to clean water and sanitation.

Scaling Up and Future Prospects

To adapt the system for full-scale applications, further work is underway to optimize fiber distribution, screen durability and continuous-flow operation. Large-scale deployment will also require automating the pressing system and evaluating long-term mesh performance.

This technology could eventually replace or complement conventional units, providing an affordable and sustainable alternative for both drinking water and wastewater treatment. By merging nature-based materials with engineered design, this study demonstrates that innovative science can translate directly into practical benefits for communities worldwide.

Conclusion

The three-in-one fibrous process developed at ÉTS offers a compact, efficient and practical way to purify water and sludge simultaneously. By combining cellulose fibers and flocculants in a single unit, it simplifies treatment, reduces maintenance, and brings safe water within reach of the communities that need it most.

References

Mebarki, M., Joge Ngale, G., & Lapointe, M. (2025). Fibrous super-bridging agents simultaneously improve contaminants removal and sludge dewatering via a very compact three-in-one process. npj Clean Water.

Lapointe M, Kurusu RS, Hernandez LM, Tufenkji N. Removal of Classical and Emerging Contaminants in Water Treatment Using Super-Bridging Fiber-Based Materials. ACS EST Water. 10 Feb 2023;3(2):377‑86.

Abi Farraj S, Lapointe M, Kurusu RS, Liu Z, Barbeau B, Tufenkji N. Targeting nanoplastic and microplastic removal in treated wastewater with a simple indicator. Nat Water. Jan 2024;2(1):72‑83.

Kurusu RS, Lapointe M, Tufenkji N. Sustainable iron-grafted cellulose fibers enable coagulant recycling and improve contaminant removal in water treatment. Chem Eng J. 15 Feb 2022;430:132927.

Lapointe M, Farner JM, Hernandez LM, Tufenkji N. Understanding and Improving Microplastic Removal during Water Treatment: Impact of Coagulation and Flocculation. Environ Sci Technol. 21 July 2020;54(14):8719‑27.

WHO, UNICEF. Progress on drinking water, sanitation and hygiene: 2017 update and SDG baselines. 2017.