Equipment as a Service – More than a Simple Rental!

Purchased on Istockphoto.com. Copyright.

Current Issues Facing Quebec Industry

For the past several years, manufacturing productivity has been low in Quebec due to a lack of investment. The labour shortage, caused by aging demographics and amplified by the health crisis, is now reaching chronic levels, making it difficult to increase production capacity. One of the strategies being considered is the implementation of major technologies. But still, required liquidity or sufficient borrowing capacity are necessary to access these technologies. One solution: Equipment as a Service.

Equipment as a Service

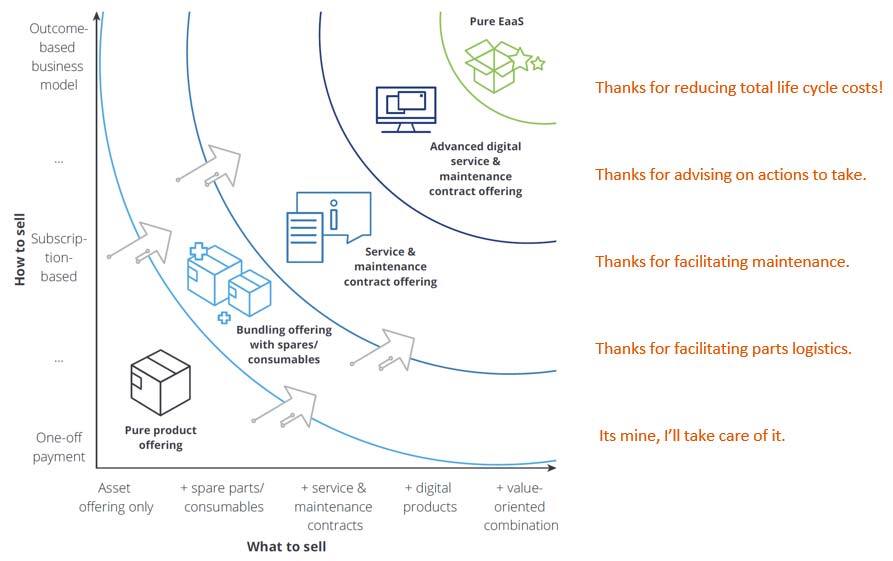

Equipment as a Service is a business model that offers comprehensive solutions. Instead of procuring equipment, a company partners with its customers to provide the output of a product, which will be charged as a service. Customers get a comprehensive solution, including service guarantees without having to make major investments. The result is lower total life cycle costs and simplified equipment operation.

Although marginal in Quebec, Equipment as a Service has been going on for decades, especially in the United States and Europe. Basically, this model takes advantage of a close partnership between suppliers and customers.

Suppliers, now responsible for their equipment, can offer more robust products that consume less energy and require much less maintenance. Thanks to 4.0 technologies, they will be able to understand the types of failures that occur and offer solutions that are much more appropriate than simply replacing parts.

A Win-Win Business Model

Users no longer have to finance their equipment. They also avoid the logistics of maintaining their equipment, such as managing spare parts, and no longer need specialized maintenance personnel. They no longer have to predict the best time to replace equipment and avoid most operational disruptions when warned by their supplier. Finally, they can focus on their own customers rather than on any equipment issues.

Suppliers, on the other hand, end up with more customers because they make it easier to access their product. They no longer have to compromise on the quality of parts and equipment. On the one hand, this business model no longer involves selling spare parts or maintenance time. On the other hand, high-quality components can be recycled from one product generation to the next. As specialists of their own equipment, they can analyze the data collected through connected objects to understand the types of failures and prevent them (maintenance 4.0). Revenues are stabilized over time. Suppliers are able to invoice an additional service with high added value for their users.

What About the Spotify Effect?

A common fear among suppliers is that Equipment as a Service will make it easier for customers to move from one supplier to another, encouraging them to negotiate contract terms. In fact, quite the opposite is observed in the field: Equipment as a Service builds customer loyalty. The user-supplier synergy helps customers become more profitable, more competitive in the international market and even capture additional market share. These successes translate into more demand for the supplier’s products.