Abstract

Power plants are among the largest sources of carbon dioxide emissions, a major driver of climate change. Capturing and storing CO2 from their exhaust streams is a promising pathway to reduce global warming while keeping electricity reliable. Yet, choosing the right capture method is not straightforward. Technologies differ in cost, energy use, and readiness for deployment. This article draws on a systematic review of recent studies and applies a structured evaluation method to compare carbon capture strategies for coal, lignite and natural gas power plants. The results show that calcium looping, and other post-combustion techniques perform best for natural gas plants, that amine absorption remains the strongest option for lignite plants, and that Selexol-based pre-combustion stands out for coal. These findings highlight how both economic and technological maturity determine the most promising solutions for near-term adoption.

Keywords: Multi-criteria decision analysis; Oxy-fuel combustion; Post-combustion; Pre-combustion; AHP; TOPSIS; CO2 capture

Graphic Abstract

Climate Challenge

The past decade has seen record-breaking temperatures, sea levels increase, and more extreme weather events. Despite international agreements such as the Paris Accord, global carbon dioxide levels keep rising, reaching 427 parts per million in 2024 [1]. If this trend continues, global CO2 concentrations could reach 550 ppm by 2050[2]. The electricity sector, which accounts for around 40% of emissions, sits at the center of this challenge. Reducing its carbon footprint is essential to stay on track with climate goals.

Carbon capture and storage (CCS) have been studied since the 1970s and is now considered one of the most important near-term solutions [3]. The idea is simple: instead of releasing CO2 into the atmosphere, it is captured at the source and either stored underground or reused in products like fuels and building materials [4]. The execution, however, is complex, and no single “one-size-fits-all” solution exists.

Capture Toolbox

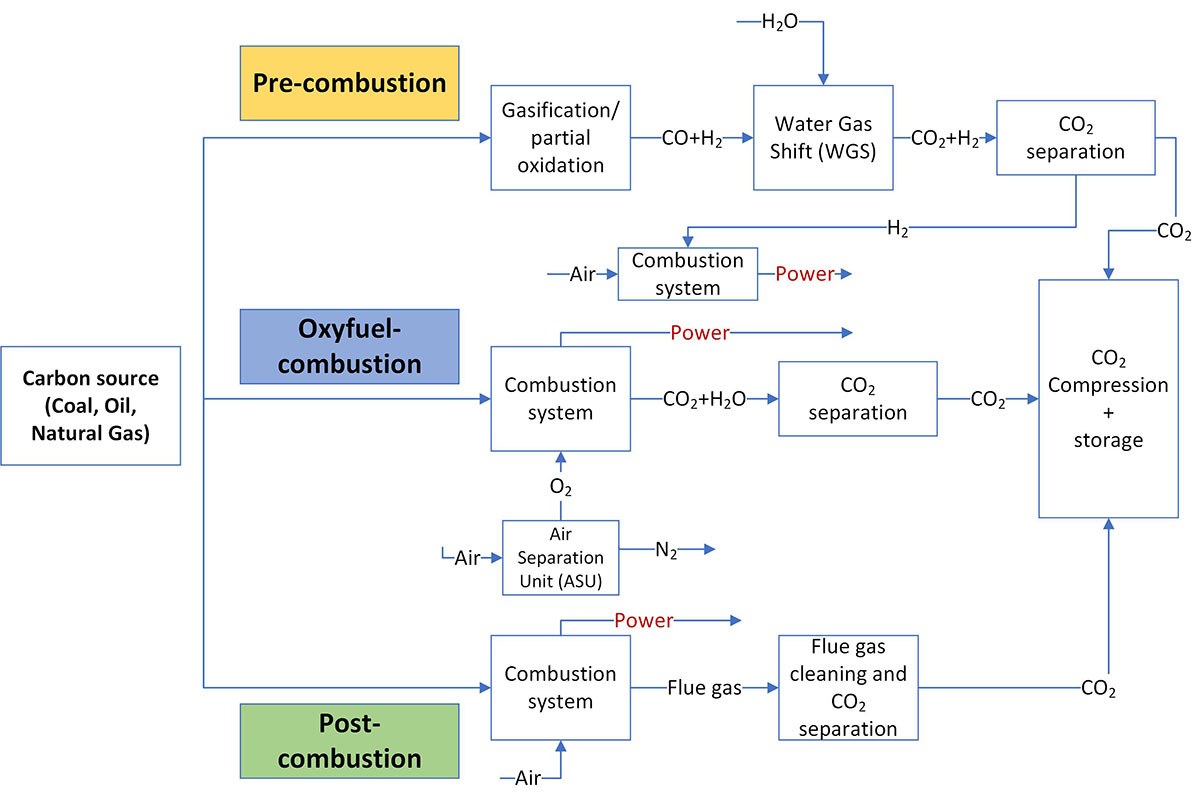

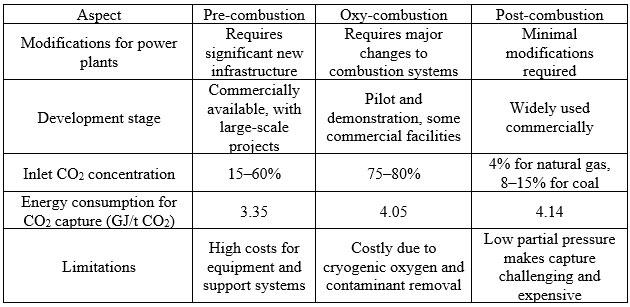

Power plants differ widely in design and fuel type, which means their CO2 capture strategies must also differ. In general, three broad approaches are used:

- Pre-combustion, removing CO2 before fuel is burned, common in gasification-based systems.

- Post-combustion, capturing CO2 after combustion, often by using chemical solvents.

- Oxy-fuel combustion, burning fuel in pure oxygen to create a flue gas rich in CO2 that is easier to separate.

These strategies can be combined with specific technologies such as absorption (liquid solvents like amines), adsorption (solid materials that trap CO2), membranes or chemical looping. Each option involves trade-offs in terms of energy efficiency, costs, and readiness for large-scale use.

Table 1: Comparison of CO2 Capture Technologies modified from [8], [9]

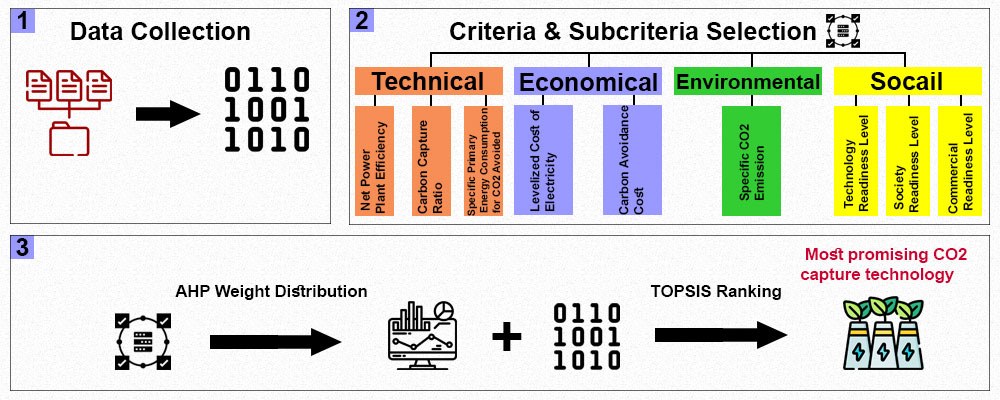

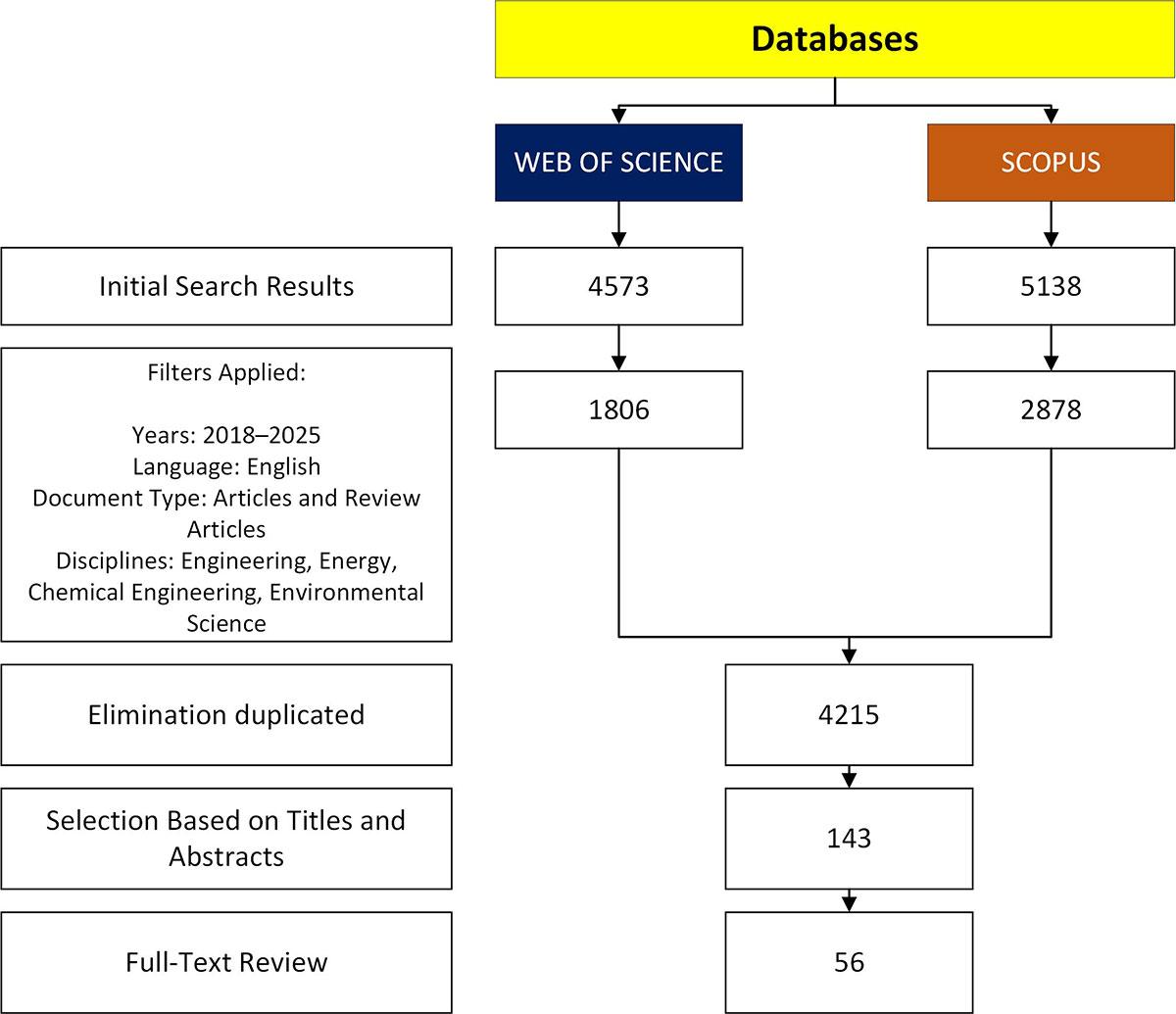

How the Study Compared the Options

To identify the most promising choices, a systematic literature review covering 2015–2024 was conducted. The review focused on technical performance (like energy efficiency), economics (cost per ton of CO2 avoided and electricity price), environmental impacts (specific CO2 emissions), and maturity indicators (technology readiness, commercial readiness, and social acceptance).

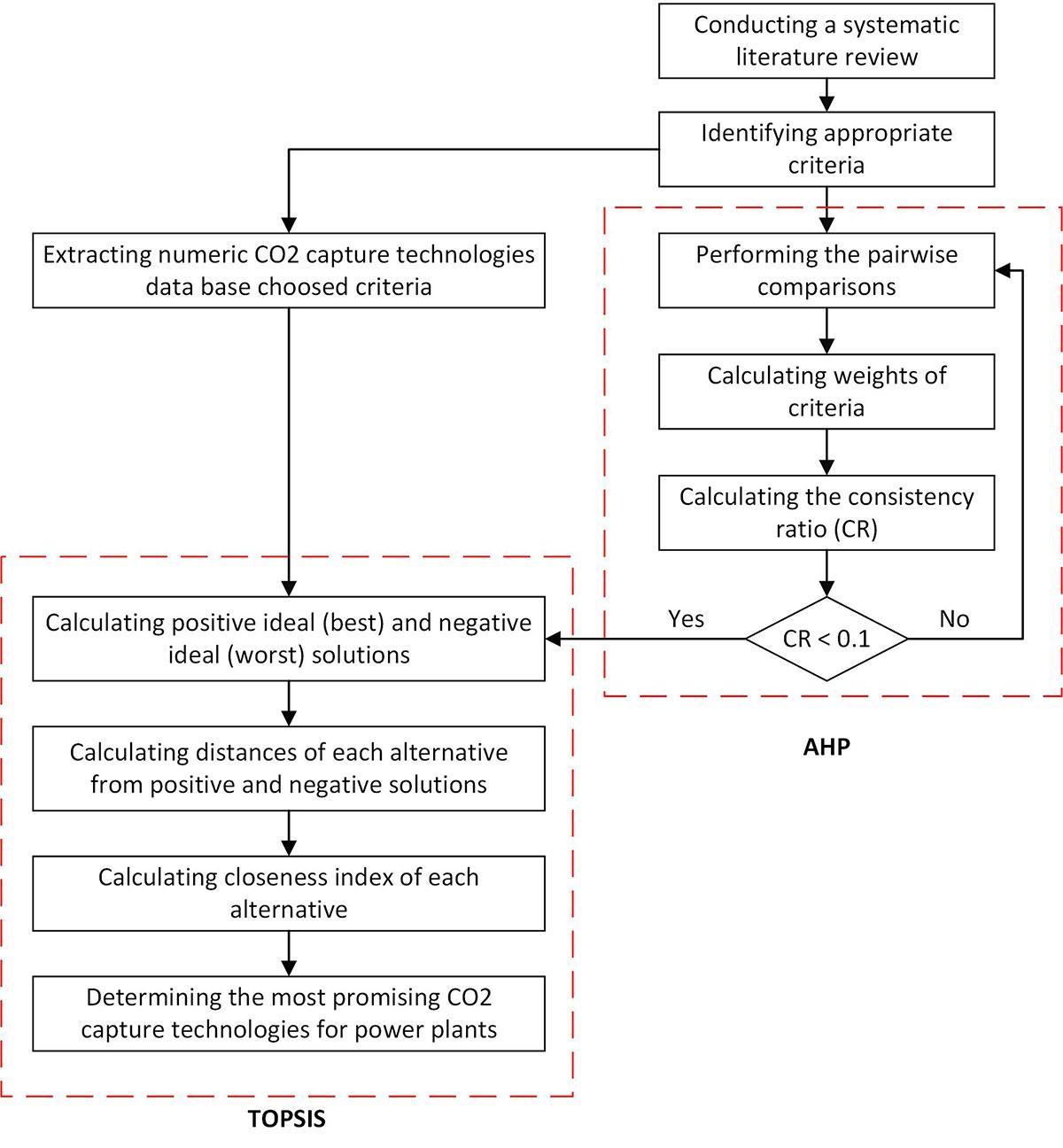

Because these factors are not equally important, a structured decision-making method was applied. The Analytic Hierarchy Process (AHP) assigned weights to each criterion, and the TOPSIS method ranked capture options by comparing them to an “ideal” solution. In this framework, economic indicators such as cost of CO₂ avoided, and levelled cost of electricity carried the most weight, followed by efficiency and readiness.

Results by Plant Type

Natural Gas Combined Cycle (NGCC):

For NGCC plants, post-combustion calcium looping emerged as the most attractive option. It combines relatively low cost ($40 USD per ton of CO2 avoided) with good efficiency (48%) and a medium-to-high readiness level. Carbonate looping also scored well, while standard amine absorption remains reliable but more expensive.

Lignite Plants:

For lignite, amine-based absorption with MDEA ranked first. This process is commercially mature (TRL 9), cost-effective (around $47.40 USD per ton of CO2), and already widely used in industry. Carbonate looping came close behind, particularly in scenarios where heat integration lowers energy penalties.

Coal Plants:

Coal plants presented a different picture. Pre-combustion capture using the Selexol process combined with chemical looping achieved the best results. It offered the lowest cost of avoided carbon ($23.70 USD per ton) and decent efficiency (37%). Oxy-fuel combustion appeared as a competitive alternative depending on the oxygen supply system, though it still faces cost and infrastructure hurdles.

Key Takeaways

Across all three plant types, one trend stood out: cost matters most. The cost of avoided CO2, and the overall price of electricity were the strongest drivers in determining the top technologies. Technical efficiency came second, followed by the maturity of the technology. Emerging options such as membranes or cryogenic separation did not perform well because of high energy needs, high costs or lower readiness. While they may improve with further research, they are not yet ready for widespread adoption.

Looking Ahead

CCS technologies are not a silver bullet, but they are critical for decarbonizing electricity while renewable systems continue to expand. The findings suggest that industry and policymakers should prioritize solutions that are both cost-effective and commercially mature, such as amine absorption for lignite and Selexol for coal. At the same time, investment in newer options like calcium looping is essential, since they could deliver better long-term performance once scaled up.

The future of CCS lies in balancing economics, technology readiness and environmental impact. Through careful selection and continued innovation, power plants can move from being some of the world’s largest carbon emitters to being part of the solution in meeting global climate goals[10].

References

[1] “Monthly atmospheric CO2 concentration 2024 | Statista.” Accessed: Jun. 08, 2024. [Online]. Available: https://www.statista.com/statistics/1091999/atmospheric-concentration-of-co2-historic/

[2] “CO2 Concentration.” Accessed: Jun. 08, 2024. [Online]. Available: https://www.theworldcounts.com/challenges/global-warming/CO2-concentration

[3] M. Pal, V. Karaliūtė, and S. Malik, “Exploring the Potential of Carbon Capture, Utilization, and Storage in Baltic Sea Region Countries: A Review of CCUS Patents from 2000 to 2022,” Processes 2023, Vol. 11, Page 605, vol. 11, no. 2, p. 605, Feb. 2023, doi: 10.3390/PR11020605.

[4] S. P. Filippov, “The Economics of Carbon Dioxide Capture and Storage Technologies (Review),” Thermal Engineering , vol. 69, no. 10, pp. 738–750, Oct. 2022, doi: 10.1134/S0040601522100020/TABLES/8.

[5] A. G. Olabi, T. Wilberforce, K. Elsaid, E. T. Sayed, H. M. Maghrabie, and M. A. Abdelkareem, “Large scale application of carbon capture to process industries – A review,” Aug. 15, 2022, Elsevier Ltd. doi: 10.1016/j.jclepro.2022.132300.

[6] T. M. Gür, “Carbon Dioxide Emissions, Capture, Storage and Utilization: Review of Materials, Processes and Technologies,” Mar. 01, 2022, Elsevier Ltd. doi: 10.1016/j.pecs.2021.100965.

[7] P. Madejski, K. Chmiel, N. Subramanian, and T. Kuś, “Methods and Techniques for CO2 Capture: Review of Potential Solutions and Applications in Modern Energy Technologies,” Feb. 01, 2022, MDPI. doi: 10.3390/en15030887.

[8] V. Sang Sefidi and P. Luis, “Advanced Amino Acid-Based Technologies for CO2 Capture: A Review,” Ind Eng Chem Res, vol. 58, no. 44, pp. 20181–20194, Nov. 2019, doi: 10.1021/ACS.IECR.9B01793/ASSET/IMAGES/LARGE/IE9B01793_0002.JPEG.

[9] A. Yagmur Goren, D. Erdemir, and I. Dincer, “Comprehensive review and assessment of carbon capturing methods and technologies: An environmental research,” Environ Res, vol. 240, p. 117503, Jan. 2024, doi: 10.1016/j.envres.2023.117503.

[10] N. Sepahi, A. Ilinca, and D. R. Rousse, “Multi-criteria decision analysis for evaluating carbon capture technologies in power plants,” Renewable and Sustainable Energy Reviews, vol. 219, p. 115699, Sep. 2025, doi: 10.1016/J.RSER.2025.115699.