Bond-Slip Behavior of CFRP-to-Concrete Interface

Purchased from Gettyimages.com. Copyright.

Abstract: The application of externally bonded (EB) carbon fiber reinforced polymer (CFRP) systems for strengthening deficient reinforced concrete (RC) structures is widely approved in the construction industry. CFRP-to-concrete bond-slip behavior governs the effectiveness of EB-CFRP systems, since interfacial debonding leads to premature failure of these strengthening tools. This study aims to evaluate CFRP-to-concrete bond-slip behavior under monotonic loading through a series of pull-out tests. Results show that using a CFRP fabric sheet instead of CFRP laminate can improve bond load-carrying capacity. Furthermore, a bilinear bond-slip model is proposed through analyses of databases in the literature. Keywords: CFRP composite; Reinforced concrete structures; CFRP-to-concrete interface; Pull-out test; Bond-slip model.

Application of Fiber-Reinforced Polymer on Concrete

The use of externally bonded (EB) fiber-reinforced polymer (FRP) composites to retrofit reinforced concrete (RC) structures has received worldwide acceptance. A common failure mode in EB-FRP strengthened concrete structures is the debonding of FRP systems from the concrete substrate, which prevents FRP composites from reaching their full tensile capacity.

Relevant test observations revealed that a typical FRP-bonded concrete specimen under monotonic loading can collapse mainly due to debonding of the concrete layer beneath the adhesive, namely, concrete surface separation [1-3]. A wide range of parameters have been investigated to better understand the behavior of the FRP-to-concrete bond. These include concrete strength, concrete surface preparation, FRP bond length, FRP-to-concrete width ratio, FRP material properties and thickness, applied adhesive epoxy and anchorage systems [4, 2, 5-12].

An experimental program in the form of double-lap pull-out testing was conducted in this study. The aim was to examine the monotonic behavior of CFRP-to-concrete interface by applying two different CFRP types (laminate “L” vs. fabric sheet “S”), different bond lengths, and different CFRP widths. The test results are mainly presented in terms of bond-slip relationships, and further discussions are included to compare the effects of experimental variables. In addition, based on experimental data analyses in the literature, a bilinear bond-slip model is proposed.

Experimental Pull-Out Testing

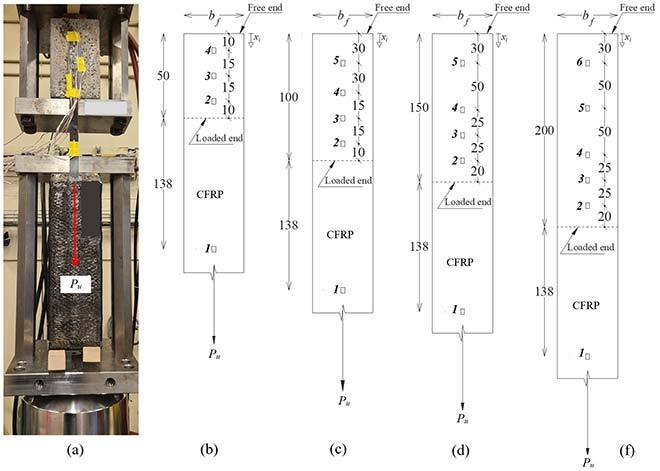

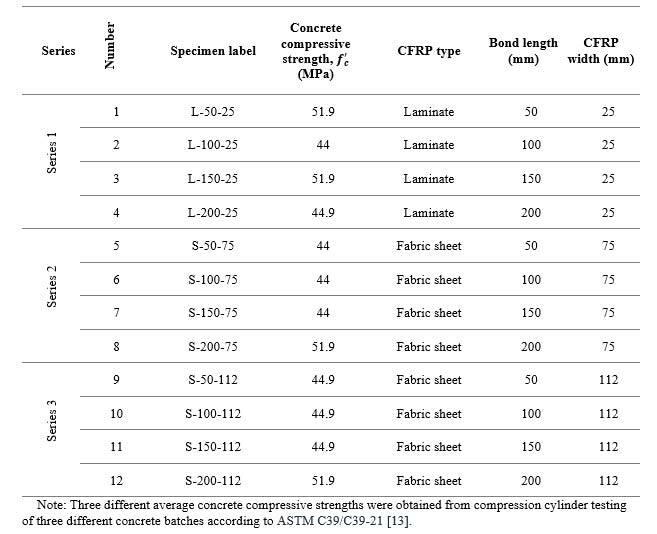

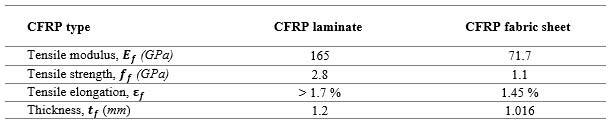

Three series of double-lap pull-out tests were performed on a total of 12 concrete blocks with EB-CFRP configurations (see test set-up in Fig. 1 (a)). The variables include CFRP type (laminate vs. fabric sheet), bond length, Lb, (50 mm, 100 mm, 150 mm & 200 mm) and CFRP width, bf , (25 mm, 75 mm, 112 mm), as presented in Table 1. The CFRP material properties are also summarized in Table 2. Several strain gauges were affixed along the bonded length of the CFRP composite to capture the strains, εi, during the monotonic testing (see Fig. 1 (b), (c), (d) & (f)).

Fig. 1. Pull-out test set-up and strain gauge configurations of specimens with different bond lengths: a) Specimen L-200-25; b) Lb= 50 mm; c) Lb= 100 mm; d) Lb= 150 mm; and f) Lb= 200 mm (all dimensions in mm)

Table 1. Experimental details of specimens

Table 2. CFRP material properties

Experimental Observations of CFRP-to-Concrete Bond Behavior

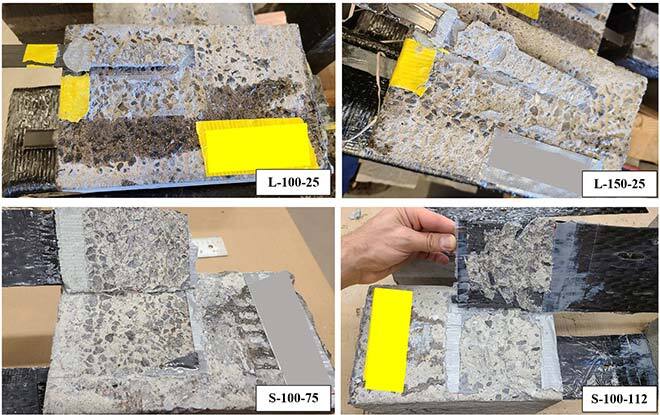

The main debonding failure mode of specimens occurred as a result of concrete surface separation (see Fig. 2). This mode of failure is evidenced by the ruptured concrete layer visible on the debonded CFRP. Indeed, this is attributed to the lower tensile strength of the concrete substrate in comparison with epoxy and CFRP composites. Similar studies have also revealed that the failure of FRP-bonded concrete specimens under monotonic loading is mainly governed by the initial failure of concrete substrate [1-3].

Fig. 2. Concrete surface separation failure mode

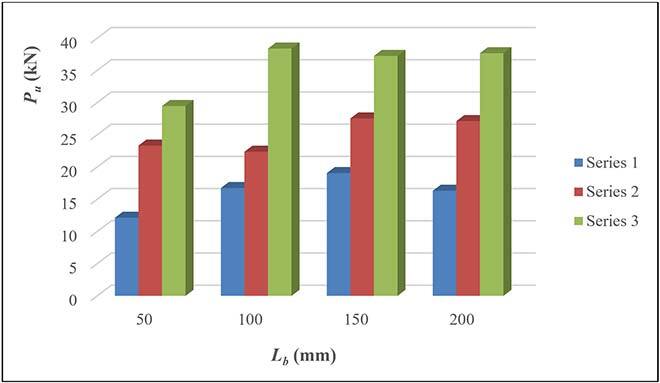

Fig. 3 shows the pull-out force (i.e., bond strength) versus the bond length of specimens under monotonic loading. The bond strength generally increased with increasing the bond length, until the effective bond length. In other words, the maximum pull-out force, Pu, of specimens with bond lengths greater than the effective bond length remained almost the same. Furthermore, specimens with a CFRP sheet reached higher bond strengths compared to their counterparts with laminate. Finally, increasing the CFRP width has shown to improve the bond strength.

Fig. 3. Pull-out force (Pu) vs. bond length (Lb)

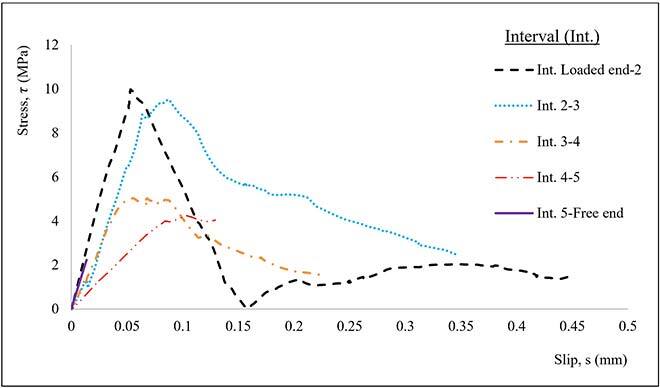

The bond-stress slip curves of Specimen S-150-112 are shown in Fig. 4. As we can see, the curves at different intervals of the bonded length generally show an ascending segment followed by a descending segment. Furthermore, the intervals closer to the loaded end carry higher bond stresses compared to intervals near the free end.

Fig. 4. Bond-slip curves of Specimen S-150-112

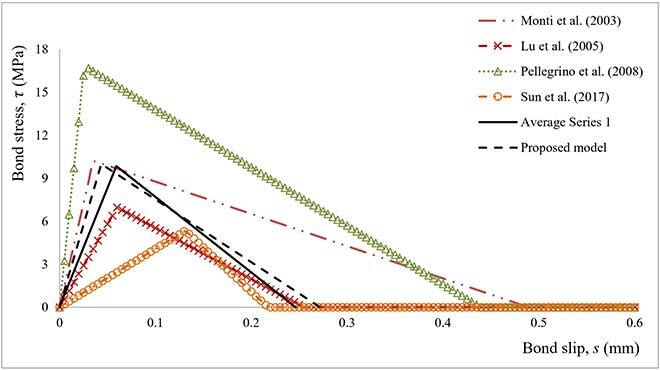

A bilinear bond-slip model was proposed during an analytical investigation to predict the bond-stress slip responses. Fig. 5 shows the average experimental bond-slip relationship of Series 1 specimens along with the corresponding predictions derived from the proposed model versus other existing models in the literature [14-17]. As we can see, the predicted results by the proposed model are in better agreement with the experimental data compared to other models.

Fig. 5. Average bilinear bond-slip curves of Series 1 specimens

Conclusion

An experimental study was conducted to examine the CFRP-to-concrete bond-slip behavior under monotonic loading. It was found that the concrete substrate is the weakest link during the debonding failure. Also, of all specimens tested, those with a CFRP fabric sheet and larger bonded width showed the best performance in terms of bond strength. Finally, a bilinear bond-slip model was proposed through an analytical study and its predictions were verified with the experimental data. Findings of this research can better familiarize civil engineers with the application of EB-CFRP strengthening techniques on concrete surfaces and therefore enhance the design of such retrofitting systems in deficient real-life RC structure.

Additional Information

For more information on this research, please see the following article: Fathi A, El-Saikaly G, Chaallal O. Experimental and Analytical Study of Bond Stress-Slip Behavior at the CFRP-to-Concrete Interface. Journal of Composites for Construction. American Society of Civil Engineers (ASCE). https://doi.org/10.1061/JCCOF2.CCENG-4074. 2023; Volume 27, Issue 2.