Improving the Finish of 3D Printed Parts

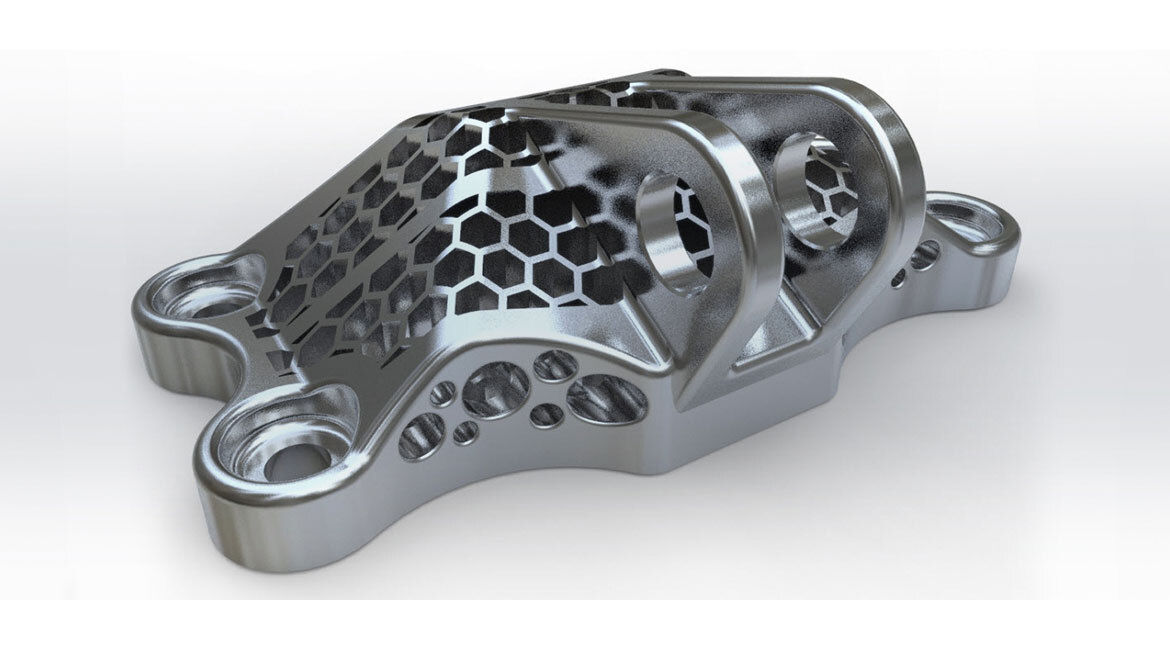

The featured image is from WH Williams. Copyrights.

Background

Frédéric Poulin was working as a manufacturing engineer in the aerospace sector when he was shown a truly complex part made by additive manufacturing. To manufacture the same component by conventional processes would have been almost impossible and its complexity would have required too many man- and machine-hours. In addition, due to its particular configuration, the part produced by additive manufacturing was lighter and had much better mechanical properties. It did, however, have a major flaw: its surface finish was too rough.

A specialist in tribology and metrology, Frédéric Poulin had several ideas on how to solve this problem: FZ Engineering was born a few months later.

A Turnkey Product

FZ Engineering activities cover three areas: consulting/design, manufacturing and surface finishing. The company’s goal is to make additive manufacturing more available to supply chains.

Although additive manufacturing allows the development of complex, light and effective parts, it produces parts with a rough finish, reducing their aerodynamic properties, their resistance to fatigue when subject to surface tension and compression, and mechanical resistance during their life cycle. FZ Engineering can improve the internal or external surface finish of the parts while preserving the geometric integrity and dimensional accuracy sought by their customers. All their processes are fully automated. The loss of material is limited and controlled, which is a definite advantage when it comes to expensive materials. Also, the company collects a large amount of data by testing different geometries, thereby constantly pushing the limits of their knowledge in this area. FZ Engineering is one of the first organizations to tackle the problem of roughness on freestanding surfaces, a phenomenon related to 3D manufacturing. The company works in several fields: medical, military, aerospace and tooling.

Innovative Research and Development Projects

FZ Engineering collaborates with several Montreal universities including Concordia, McGill and Polytechnique. At ÉTS, the company develops some products with the ÉTS Research Chair in Engineering of Processing, Materials and Structures for Additive Manufacturing.

CRIAQ Project

One CRIAQ research project, carried out in collaboration with several partners, including FZ Engineering and ÉTS, is to build one of the first complete supply chains in additive production. The project will span a two-year period.

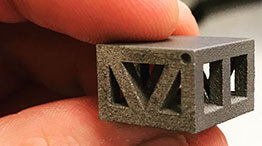

3D printed titanium structure

The same 3D printed titanium structure after post-treatment by FZ Engineering

Two surface post-treatment processes from FZ Engineering are currently in final qualification for commercial aeronautical certification from a major customer. This process could attract other large customers in the field.

SAMUEL Eureka ITEA 3 Project on Advanced Manufacturing (Smart Additive Manufacturing)

The goal of this project, consisting of six Canadian companies and European collaborators, is to build a huge database on the current knowledge of additive manufacturing to help businesses move toward Industry 4.0. Each process to date will be recorded as well as the characteristics and properties of the parts it produces. As part of this project, FZ Engineering will demonstrate the surface quality and dimensional accuracies that can be achieved with its post-processing technologies.

Today, FZ Engineering is well positioned to improve large-scale parts manufacturing for the aerospace industry. Thanks to the networks it has set up, it is a safe bet that this young company will become a key player in the field of additive manufacturing, a market valued in excess of US $12.8 billion.