LAMSI - Shape Memory Alloys and Intelligent Systems Laboratory

LAMSI in brief

The Shape Memory Alloys and Intelligent Systems Laboratory (Laboratoire sur les alliages à mémoire et systèmes intelligents – LAMSI) promotes the design and development of shape memory alloy components for various industrial applications. Its mission is to serve as a bridge between theory and practice for shape memory alloys and smart systems that use these materials.

Since 2015, the LAMSI team has worked on numerous projects involving additive manufacturing, which is at the forefront of mechanical design, materials science and manufacturing.

LAMSI is affiliated with CREPEC, a multi-institutional research center that specializes in the development, transformation and processing of new advanced materials.

From idea to functional prototype in one lab

— Vladimir Brailovski, director of the Shape Memory Alloys and Intelligent Systems Laboratory

Vladimir Brailovski is a Full Professor in the Mechanical Engineering Department and a renowned Researcher who specializes in the design and manufacturing of shape memory alloy components, with a focus on industrial applications. His areas of expertise also include process engineering for additive manufacturing (AM).

HI-AM (Holistic Innovation in Additive Manufacturing) 2023 conference

Congratulations to Donatien Campion who received the 2nd place award for his poster presentation ! His poster was about Performance Evaluation of Machine Learning Models in the Prediction of Melt Pool Dimensions and Density in Laser Powder Bed Fusion.

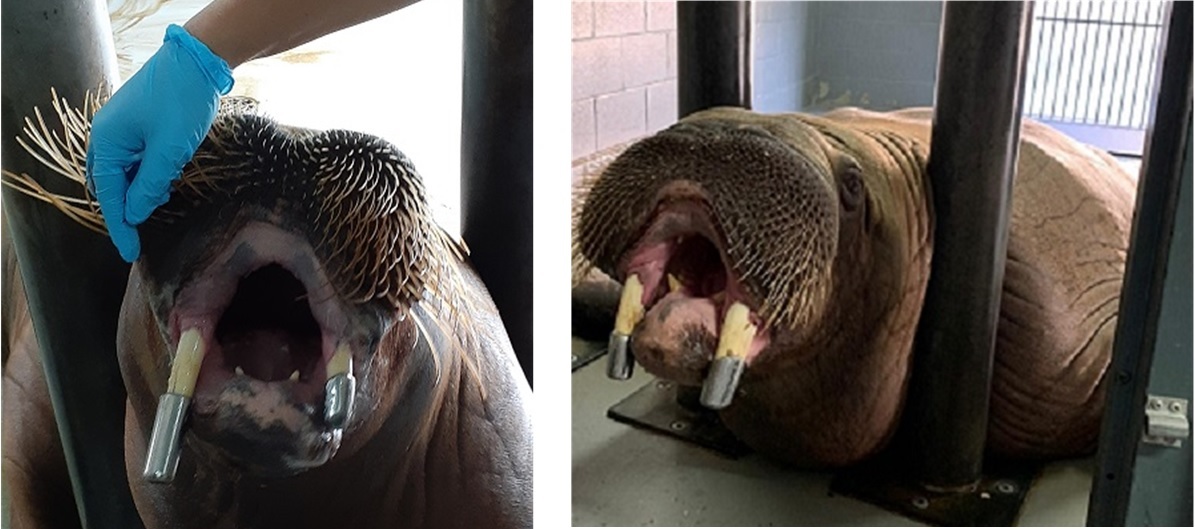

New tusk prosthetic crowns for Lakina and Balzak !

LAMSI team visited the Aquarium of Québec to bring its female and male walruses, Lakina and Balzak, new personalized 3D printed tusk crowns. The 6-year-old female initially received a cobalt-chromium prosthetic crown for its left tusk in 2020. Now, both of them have two tusk prosthetic crowns. Come visit them and see their brand new smile at the Aquarium !

First time in Quebec : surgical implantation of an ocular prosthetic for a striped bass.

The LAMSI team got involved in the installation of an ocular prosthesis of a one eye blind striped bass. With a 3D printed adjustable chirurgical guide and the use of marine epoxy, the team was able to modify a taxidermy eye to make it fit into the fish's eye socket. This operation, led by Dr. Claire Grosset, professor at Université de Montréal, is a first of its kind in Quebec. Thanks to Krystel Lacasse-Aubin who took the pictures.

Discover the projects we published in Sustance, the ÉTS popularization portal

- Optimized,Customized 3D-Printed Steering Wheel for Baja SAE

- Production kit for reusable respirator masks

- 3D-printed prosthetic crowns for walrus tusks

- 3D-printed model of implant for pectus excavatum

- 3D-printed personalized canine protheses

- Structural design challenge for a C-class catamaran

- Printing a 3D stomach teaching tool for bariatric surgery

- Additive manufacturing of Argon 18's olympic race bike stem

- Optimizing spinal implants through modeling

- Making the most of additive manufacturing

- Increasing hip prostheses' lifespan

- Design and additive manufacturing of mast foot and support for a C-class catamaran

- A 3D-printed frame assembly for a quadrorotor drone

Industrial Collaboration: LAMSI can help you innovate!

Because we work on all of the various aspects of additive manufacturing (AM), LAMSI is a great place for AM experts to receive advanced training. From developing new AM materials to designing new parts to becoming an expert in AM, LAMSI offers the best possible support.

Is your company looking to develop an innovative technology? Do you lack the expertise, time or necessary equipment to move the project forward? Have you considered collaborating with LAMSI? We might have exactly the expertise and equipment you need!

We can also help to train highly qualified personnel.