Products, Processes and Systems Engineering Laboratory (LIPPS)

Established in 1998, the Products, Processes and Systems Engineering Laboratory, which comprises more than 95 members, is a leader in its sector in Canada. LIPPS conducts research aimed at creating, validating and optimizing products, processes and manufacturing systems, focusing on a multidisciplinary approach that incorporates mechanical engineering, software engineering and industrial engineering concepts.

LIPPS stands apart because of its approach, which combines applied research with industrial development activities.

Research

Research at LIPPS revolves around two complementary axes in modern industry.

Axis 1: Physical domain (materials, tools, processes)

- Optimization of manufacturing processes (machining, welding, grinding, rapid prototyping, moulding and numerically controlled machining)

- High-speed machining and clean machining (environmentally friendly machining that respects workplace safety standards)

- Instrumentation and control of processes and products (non-destructive control)

- Automatic metrology and inspection (CMM, post-processor, vision and laser scanner)

- Materials characterization

- Recycling and reuse of materials

- Tool life and machinability testing

- Materials and composites processing

Axis 2: Virtual domain (CAD/CAM, digitization and optimization of manufacturing processes)

- Design for efficient manufacturing and assembly

- Integrated engineering methods, models and tools (CAD, CAM, FE, integrated technical data management)

- Dimensional and geometric variation management (tolerancing, planning sheets, process capabilities)

- Product lifecycle management and engineering change management

- Design of experiments (DOE), statistical data analysis and optimization

- High-performance machining of light alloy aeronautic parts

- Integrated product process change management

- Multidisciplinary optimization standardization approach for integration and configurability

- Dust-free composite machining

- Geometric inspection and tolerancing of flexible parts

- Formal representation of multi-axis machining processes for the generation of machining characteristics

- Technological derivation link for capturing and exploiting product-process constraints

- Manufacture of axisymmetric parts with complex high-resistance steel profiles

- Development of an infringement detector for CAD models

- Improvement of plantar prosthesis manufacturing processes

- Prediction of the effect of high-speed machining residual constraints

- Optimization of geometric variation management processes applied to mechanically-welded metallic structures

- Analysis of production-line measurement systems for LPM batteries

- Residual reliability of hydraulic turbines

- Characterization of copper alloys

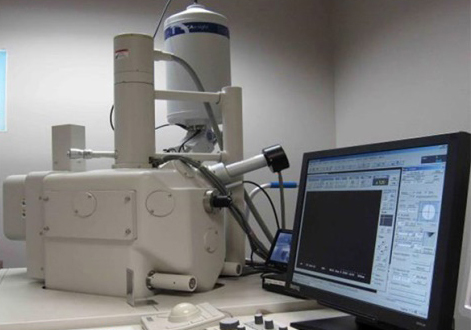

The Materials Characterization Laboratory is a one-of-a-kind facility that is fully integrated into research related to clean manufacturing. It contains the following equipment, among others:

- Atomic force microscope (AFM)

- Variable-pressure scanning electronic microscope

- Confocal laser scanning microscope

- 120,000 fps high-speed camera

- FTIR infrared spectrometer

- 200 kN high deformation tension/compression machine

- Tension/compression/torsion machine and environment room

- Thermal and thermogravimetric analysis system (DTA, TGA: 25 °C to 1500 °C)

- Gas analyzer

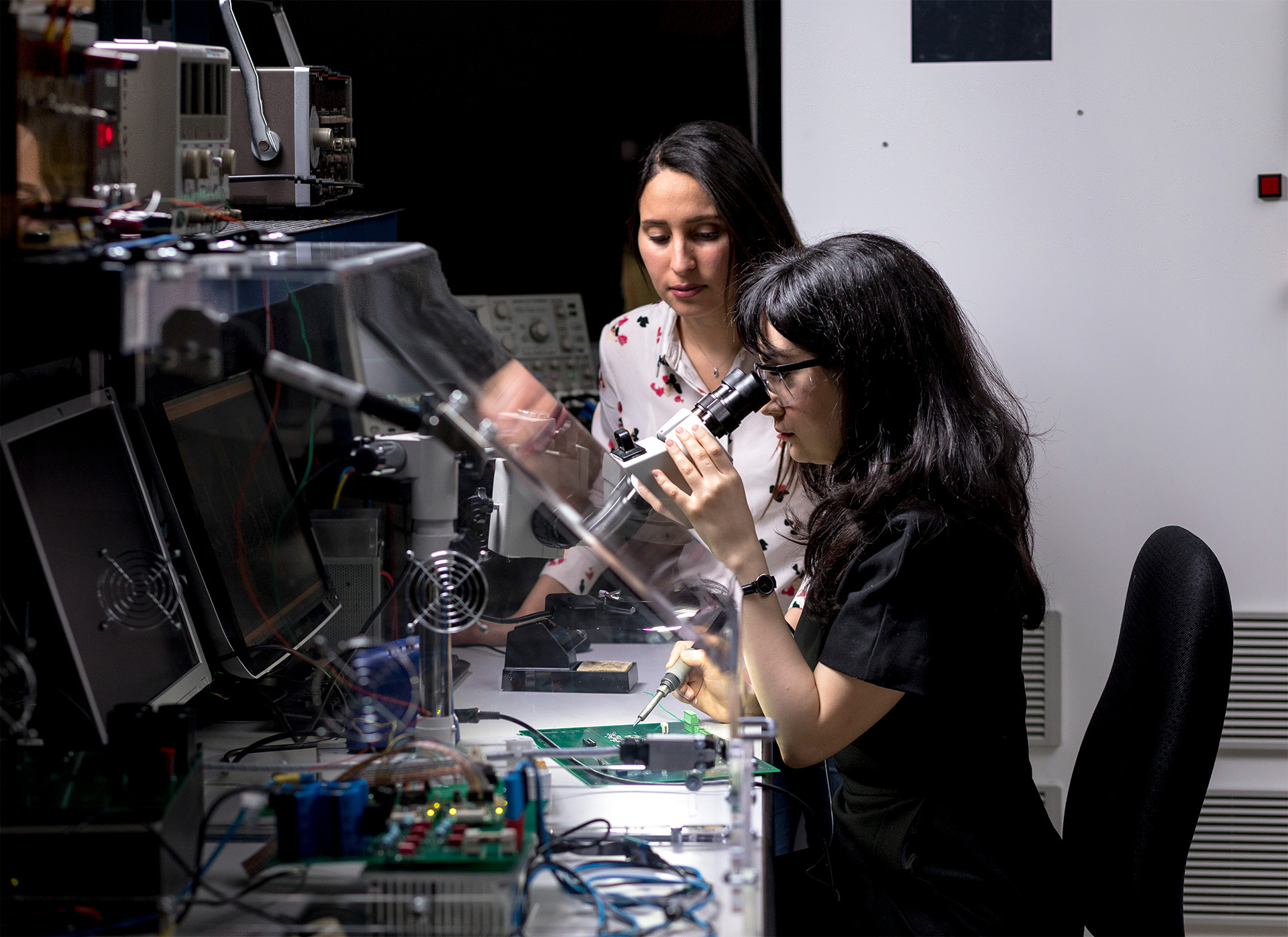

The Manufacturing Laboratory features cutting-edge industrial production and design equipment and dimensional measurement equipment, and has CAD/CAM/CAI software installed on its computers. It contains the following equipment, among others:

- INTEGREX 200 IIIST CNC turning & milling centre (Mazak, 2004)

- Huron K2X10 High-speed CNC milling machine (Huron Graffenstaden, 2007)

- NEXUS 410A 3-axis CNC milling machine (Mazak, 2004)

- NEXUS QT100 3-axis CNC milling machine (Mazak, 2007)

- Hitachi-Seiki VS50 5-axis CNC milling machine (1998)

- Mazak Variaxis i-500 5-axis CNC milling machine (Mazak, 2013)

- KUKA KR 160 R1570 Nano High-payload industrial robot (Kuka, 2014)

- Prodigy Plus Melt-deposition rapid prototyper (Stratasys, 2001)

- Bright Strato 7106 5-axis CMM (Mitutoyo, 2004)

- Keyence VHC-500F Digital microscope (Keyence, 2011)

- Mitutoyo SJ400 Contact profilometer

- Creaform EXAscan Portable 3D scanners (2011 and 2015)

- Kistler 9255B 3-axis dynamometer

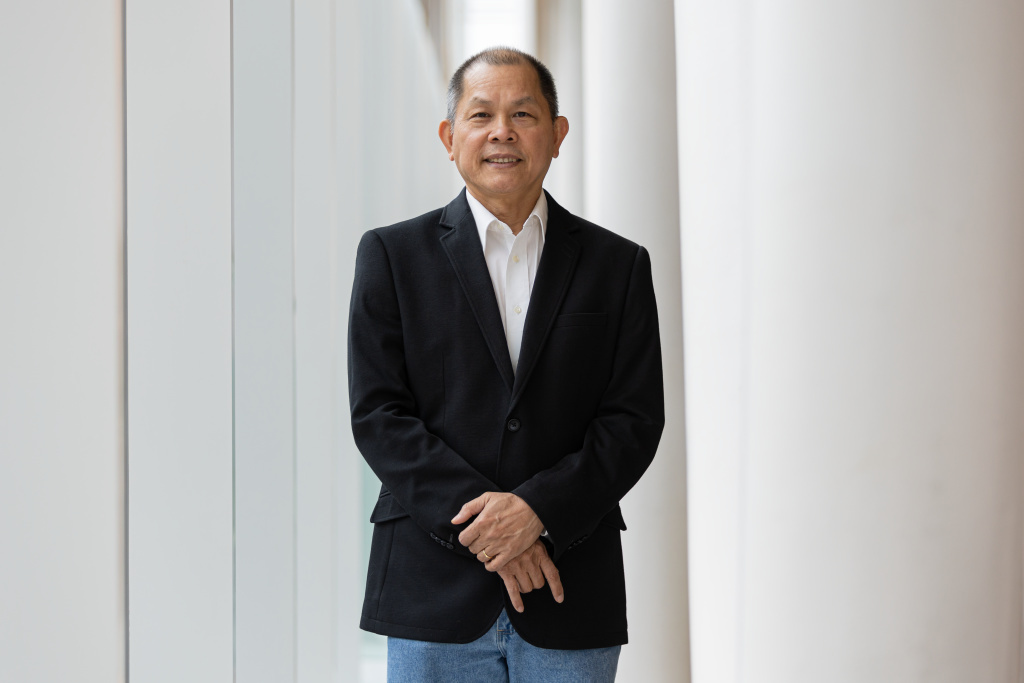

Team

Research Staff

- Mahshad Javidikia, PhD, Research Assistant

- Jules Kouam, PhD, Research Associate

- Morteza Sadeghifar, PhD, Research Associate

- Davood Shahriari, postdoctoral fellow, researcher

Institutional partners

- Aluminium Research Centre (REGAL)

- Industrial Research Chair in Forming Technologies of High Strength Alloys (CM2P)

- Natural Sciences and Engineering Research Council of Canada (NSERC)

- Consortium for Research and Innovation in Aerospace in Québec (CRIAQ)

- Canada Foundation for Innovation (CFI)

- Fonds de recherche du Québec - Nature and technologies

- Institut de recherche Robert-Sauvé en santé et en sécurité du travail (IRSST)

- Mitacs

Industrial partners

Contact us

Research at ÉTS

ÉTS provides an ideal environment for conceiving and creating the ideas that will shape the world of the future.