Research areas

Research areas

The research conducted at LIPEC contributes to technical and scientific advances, and more specifically, leads to the creation or enhancement of polymers and composite materials and facilitates the transfer of new knowledge related to real-world applications for industry.

Development and processing of functional thermoplastics

This research area is divided into three major components:

- Thermoplastic-based functional blends and nanocomposites;

- Rheology;

- Electrospinning and additive manufacturing.

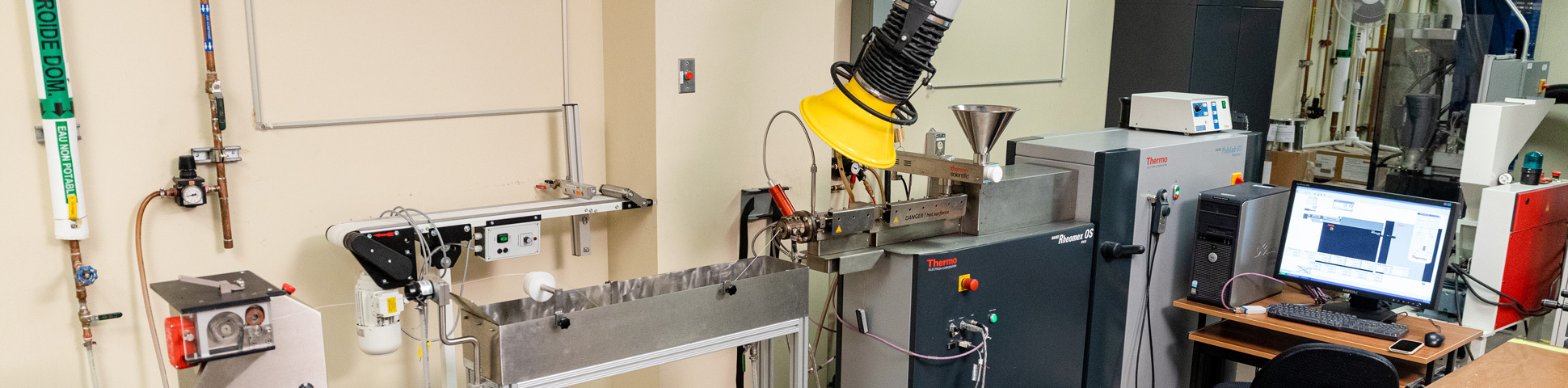

The researchers at LIPEC are working on a number of projects involving the development of new polymer-based materials, polymer blends and functional fillers. Applications are beneficial to the electrotechnical, biomedical, aerospace, transportation and packaging sectors. The development of these materials relies on a fundamental knowledge of rheology and polymer science.

We are also studying manufacturing methods, including the modification of traditional plastic processing methods and the development of innovative nano- and micro-manufacturing methods, such as electrospinning and additive manufacturing. We have access to a semi-industrial electrospinning machine that allows us to produce non-woven membranes that can be used for biomedical applications, in smart textiles, for separating different fluids and for filtration.

Processing of high-performance composites

- Thermoplastic composites: Compression moulding, thermoforming, welding, 3D printing

Research work under the thermoplastic composites component targets the development of processing and assembly processes involving welding and other procedures. The focus is just as much on low-TRL (Technology Readiness Level) projects, where processes and materials are developed, as on high-TRL projects, where we work with our industrial partners on the automation and industrialization of processes.

The welding processes available at LIPEC include resistance welding and induction welding, along with laser welding and ultrasound welding, which were developed in cooperation with industrial partners.

LIPEC also conducts research projects related to compression moulding and thermoforming of thermoplastic composites in connection with the recycling of composite materials and the recovery of production scraps.

- Thermosetting composites: RTM, infusion

Research work under the thermosetting composites component primarily targets injection moulding manufacturing processes: RTM (Resin Transfer Moulding), infusion and others. The objective of our research activities is to promote the emergence of new advanced industrial applications based on a variety of basic or applied concepts:

- Process automation;

- Development of manufacturing moulds;

- Digital simulation of processes and virtual manufacturing;

- Modelling of flow phenomena in multi-scale porous media;

- Advanced characterization of fibrous reinforcements.